Insulation double-sided tape and preparation process thereof

A double-sided tape and preparation process technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of low compounding accuracy, inability to meet the development trend of light and thin electronic products, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

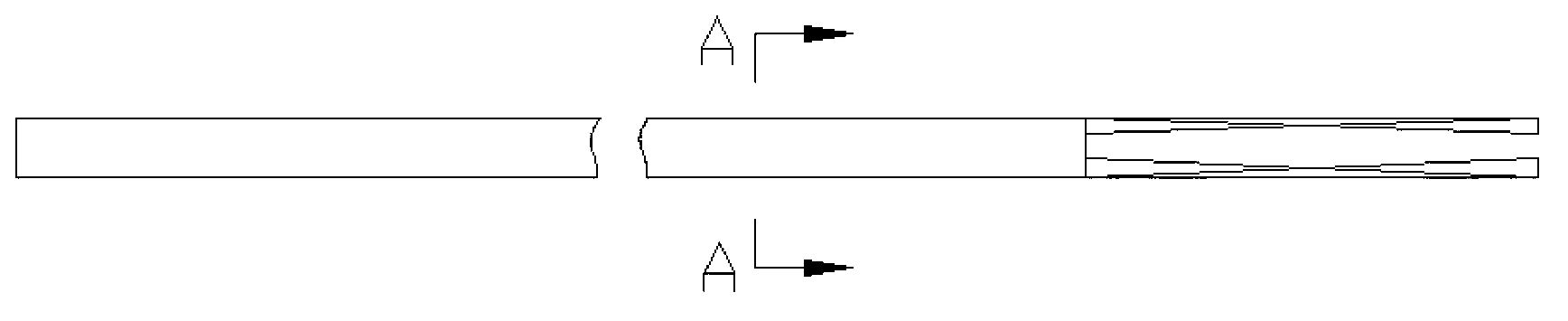

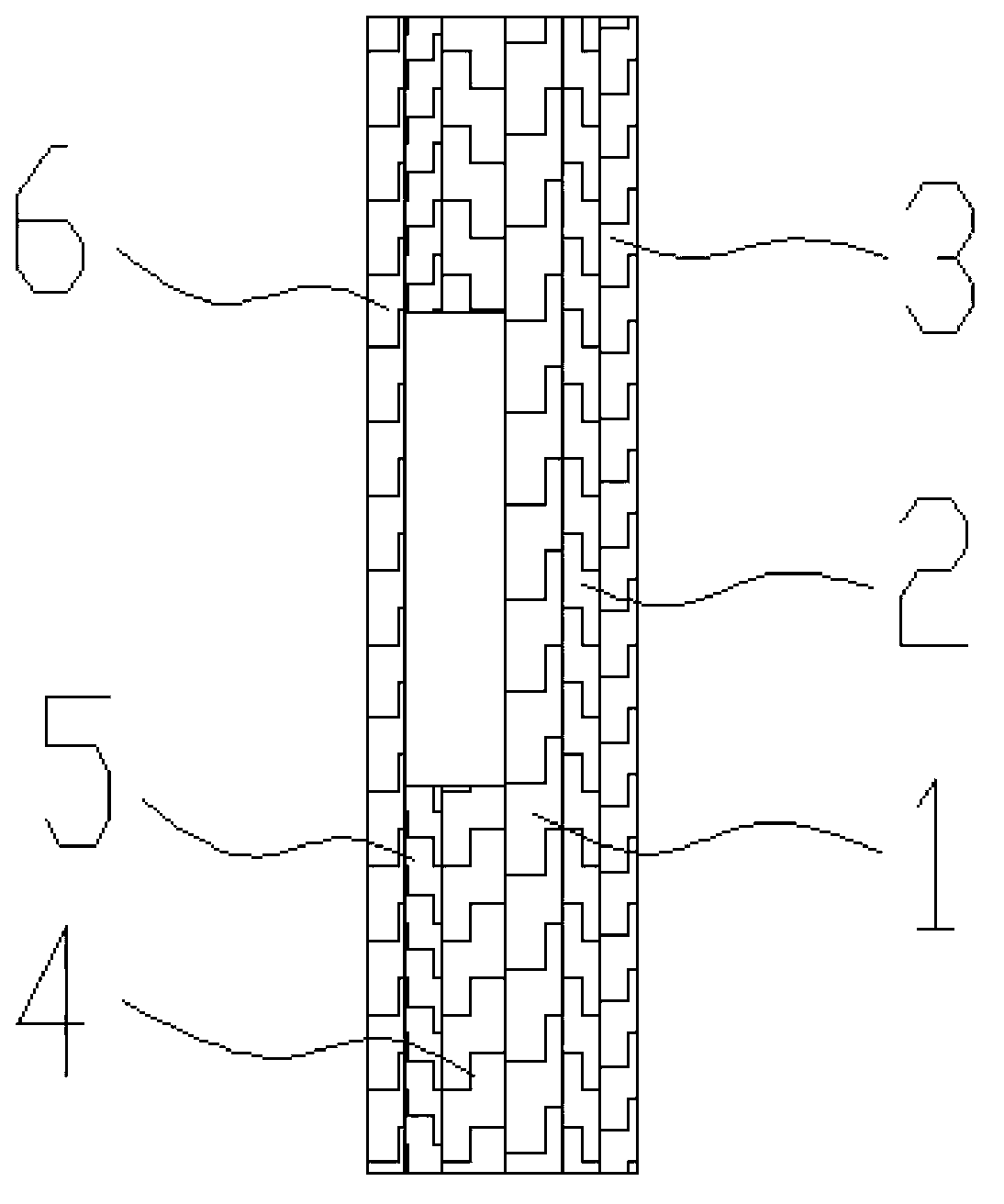

[0066] The present invention is described below in conjunction with accompanying drawing.

[0067] as attached figure 1 , 2 Shown is a kind of insulating double-sided adhesive tape according to the present invention, the first release film 3, the first double-sided adhesive film 2, the insulating film 1, the second double-sided adhesive film 4, which are aligned at one end and bonded sequentially. Two release film 5, texture protective film 6 constitute, described first double-sided adhesive film 2, insulating film 1 and second double-sided adhesive film 4 are equal in length, the other end of described first release film 3 is longer than the first double-sided adhesive film 3 A double-sided adhesive film 2 is 8mm long, and the second release film 5 is 40mm longer than the second double-sided adhesive film 4 .

[0068] The second double-sided adhesive film 4 is composed of two double-sided adhesive strips arranged at intervals in the width direction of the insulating film, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com