A kind of directional high thermal conductivity low expansion graphite aluminum composite material and its preparation method

An aluminum composite material, low expansion technology, applied in the field of metal-based graphite composite material and its preparation, can solve the problems of poor orientation of graphite flakes, inclusion density, etc., and achieve the effects of low cost, increased density, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

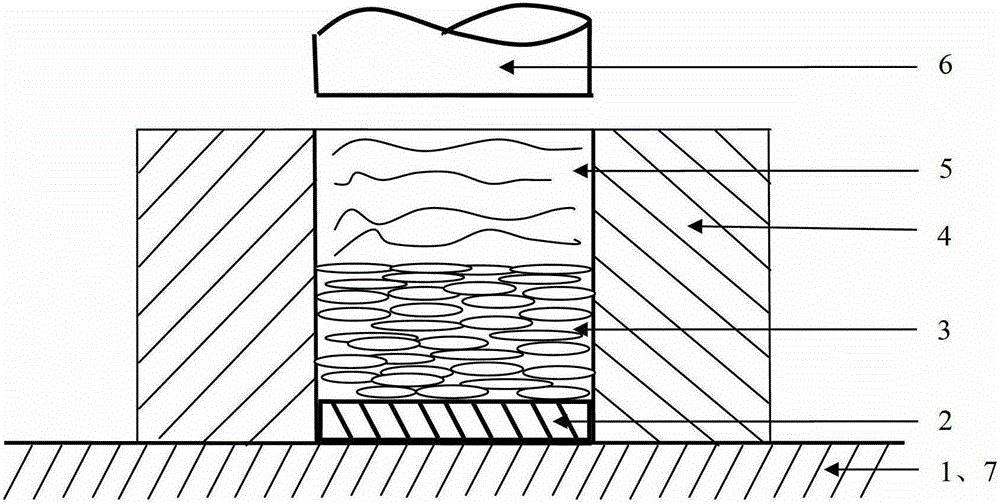

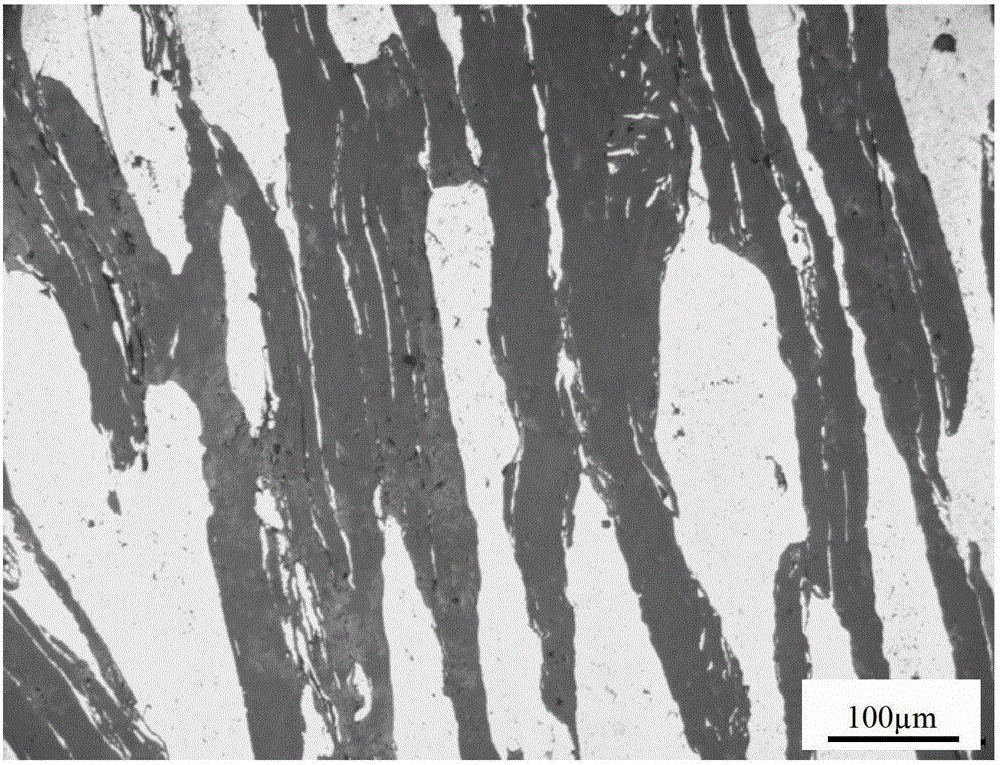

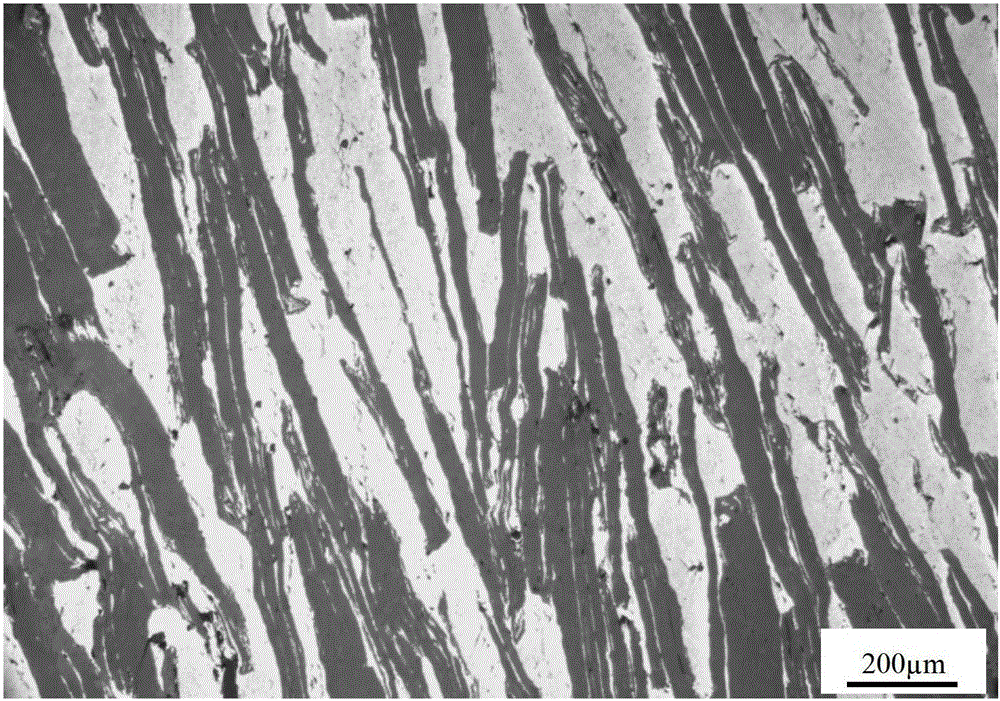

[0020] Specific implementation mode 1: In this embodiment, the oriented high thermal conductivity and low expansion graphite aluminum composite material is made of oriented arranged flake graphite and aluminum metal, the aluminum metal is pure aluminum or aluminum alloy, and the oriented high thermal conductivity low expansion graphite aluminum composite material is made of flakes The graphite content is 30-70vol.%, and the directional arrangement of flake graphite is formed by impact vibration.

specific Embodiment approach 2

[0021] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the aluminum metal component is pure Al, or 1~25wt.% Si is added to Al, or 1~53wt.% Cu is added, or 1~53wt.% Cu is added. 38wt.% of Mg, one or a combination of several components. Other parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: this embodiment is different from specific embodiment one or two in that the aluminum alloy is Al-Si alloy, Al-Cu alloy, Al-Mg alloy, Al-Si-Cu alloy, Al-Si-Mg alloy, One or a combination of Al-Cu-Mg alloys and Al-Si-Cu-Mg alloys, wherein Al-Si alloys are 1~25wt.% Si added to Al, and Al-Cu alloys are 1~53wt.% Cu is added to Al, and 1~38wt.% Mg is added to Al for Al-Mg alloy. Other parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com