Method for preparing long fiber reinforced ABS composite material

A composite material and long glass fiber technology, which is used in the preparation of high-performance long glass fiber reinforced thermoplastic composite materials and the preparation of long glass fiber reinforced ABS composite materials by a suspension impregnation method, can solve the problems of long time consumption, high energy consumption and cumbersome procedures. and other problems, to achieve the effect of reducing processes, low energy consumption, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

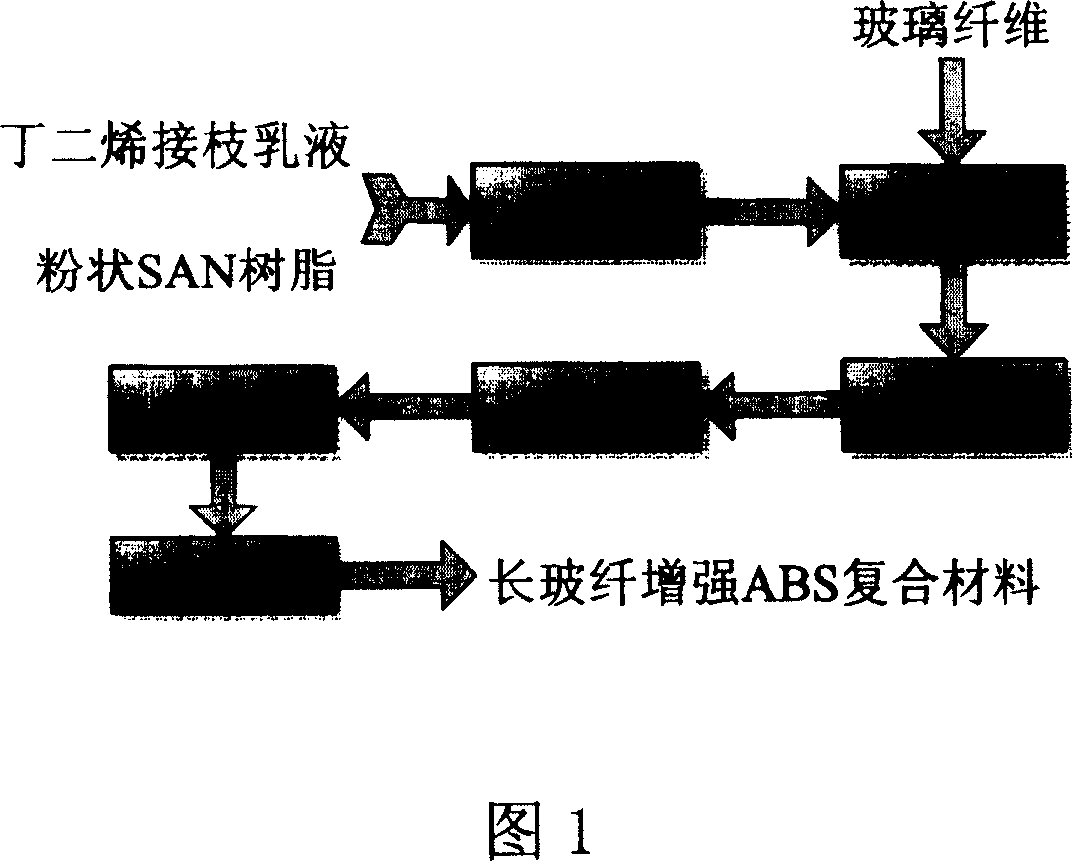

[0026] With reference to accompanying drawing 1, the intermediate butadiene graft emulsion of ABS and SAN resin powder are mixed, the dry weight of butadiene and the weight ratio of SAN are 1: 1.5, add ABS antioxidant 1010 in the mixture, high-speed stirring , to obtain a uniform suspension; place the continuous glass fiber bundle at 400 ° C for 6 hours at high temperature, cool to room temperature naturally, and then soak it in 1.5% silane coupling agent KH-550 aqueous solution for 20 minutes, and then place it in Drying in an 80°C drying oven; the continuous glass fiber passes through the suspension infiltration tank under the action of traction, is dried in an open oven, heated and melted through a closed melting pipeline, and then extruded through a mold, and pelletized to obtain composite material slices; The composite material slices were dried in vacuum at 80°C for 4 hours, and then injection molded by an injection molding machine to obtain long glass fiber reinforced AB...

Embodiment 2

[0028] With reference to accompanying drawing 1, the intermediate butadiene graft emulsion of ABS and SAN resin powder are mixed, the dry weight of butadiene and the weight ratio of SAN are 1: 3, add ABS antioxidant 1010 in the mixture, high-speed stirring , to obtain a homogeneous suspension; place the continuous glass fiber bundle at 450 ° C for 4 hours at high temperature, cool to room temperature naturally, and then soak it in 1.5% silane coupling agent KH-550 aqueous solution for 15 minutes, and then place it in Dry in a drying oven at 90°C for 2 hours; the continuous glass fiber passes through the suspension infiltration tank under the action of traction, is dried in an open oven, heated and melted through a closed melting pipeline, and then extruded through a mold and pelletized to obtain a composite material Slicing: The composite material slices were dried at 70°C for 5 hours under a vacuum degree of 0.1MPa, and injected into an injection molding machine to obtain a lo...

Embodiment 3

[0030] With reference to accompanying drawing 1, the intermediate butadiene graft emulsion of ABS and SAN resin powder are mixed, the dry weight of butadiene and the weight ratio of SAN are 1: 2.5, add ABS antioxidant 1010 in the mixture, high-speed stirring , to obtain a uniform suspension; place the continuous glass fiber bundle at 500 ° C for 4 hours at high temperature, cool to room temperature naturally, and then soak it in 1.5% silane coupling agent KH-550 aqueous solution for 30 minutes, and then place it in Drying in a drying oven at 70°C; the continuous glass fiber passes through the suspension infiltration tank under the action of traction, is dried in an open oven, heated and melted through a closed melting pipeline, and then extruded through a mold, and pelletized to obtain composite material slices; The composite material slices were dried in vacuum at 90°C for 3 hours, and then injection molded by an injection molding machine to obtain long glass fiber reinforced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com