High temperature-resistant casting tin bronze-cast rubbing cylinder rail wheels of graining machine

A track wheel, tin bronze technology, applied in the field of machinery, can solve the problems of deformation of the rubbing cylinder, wear iron filings, reduce the rubbing effect, etc., and achieve the effects of preventing uneven force, small wear and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

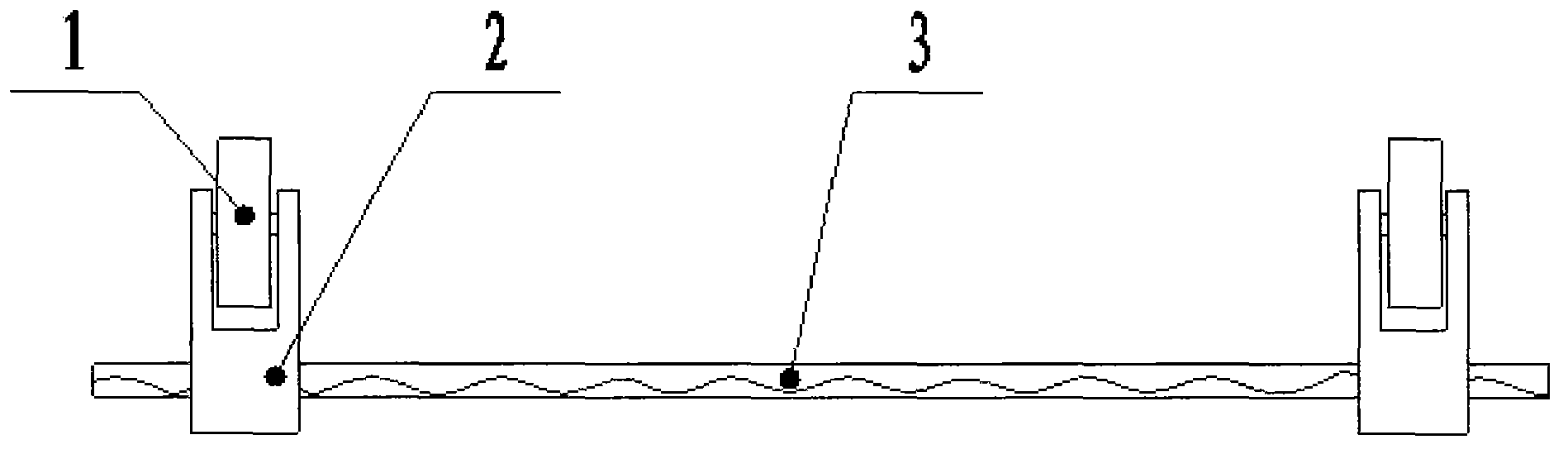

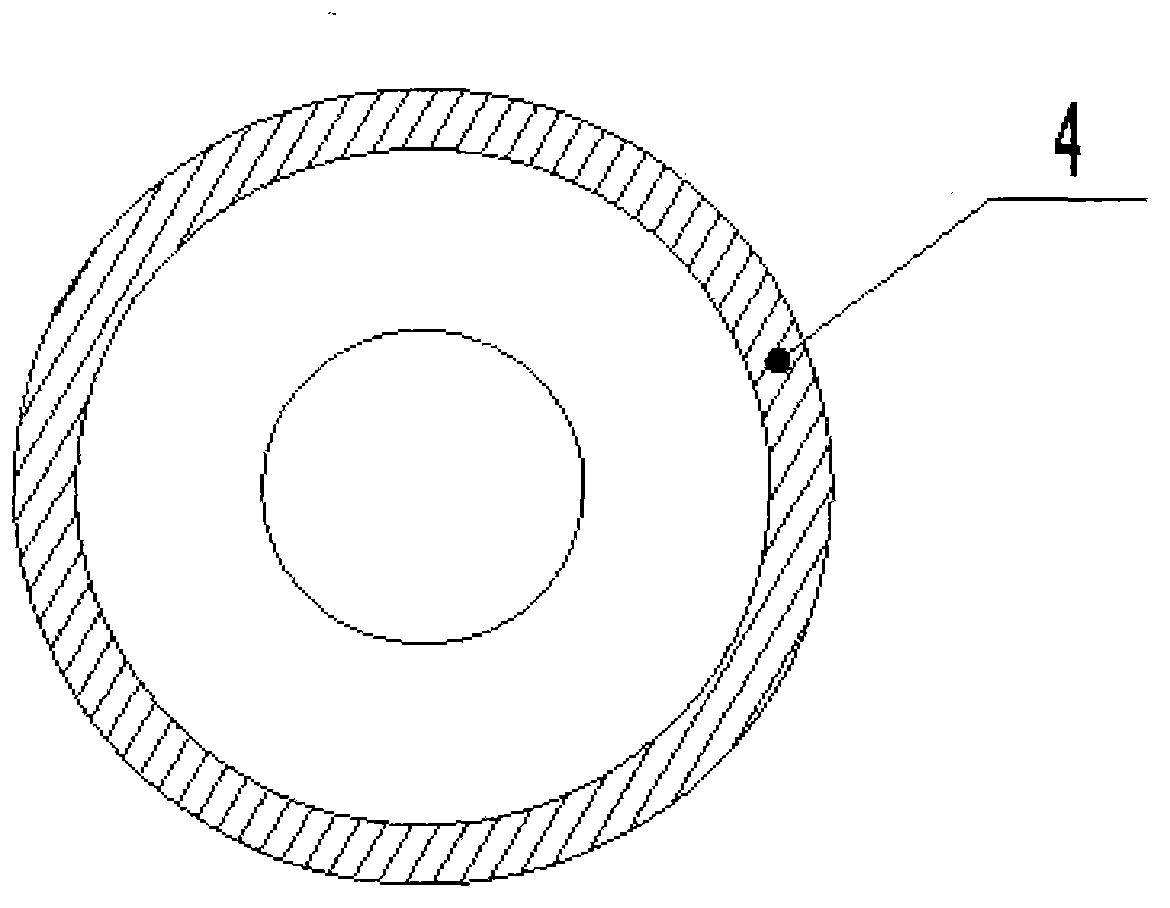

[0014] As shown in the figure, the high-temperature-resistant cast tin bronze kneading cylinder track wheel of the kneading machine includes a pair of symmetrical track wheels 1 and track wheel brackets 2, wherein a synchronous screw 3 is arranged between the track wheel brackets 2, and the track wheel 1 The outer surface is cast with tin bronze 4 at least 20mm thick.

[0015] As shown in the figure, when in use, the track bracket 2 is set on the track, and the raceway on the roller is engaged with the track wheel 1. When in use, the synchronous screw 3 on the track wheel bracket 2 can be adjusted to ensure that each raceway The distance between the track wheels 1 can prevent uneven stress caused by the deformation of the roller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com