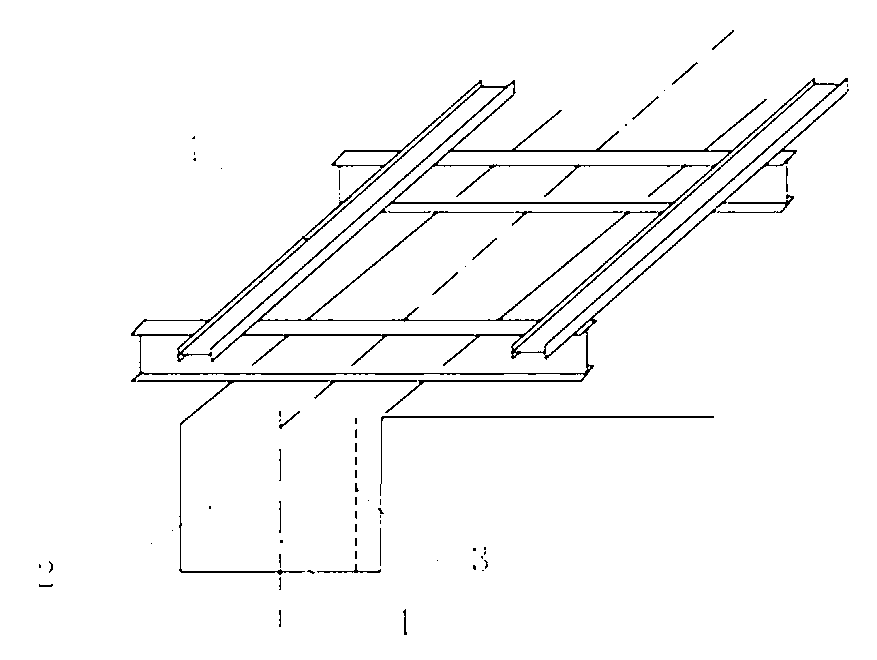

Long auger rotary-jet mixing steel reinforced cement-soil pile foundation pit water-resisting and supporting method

A technology of cement-soil piles and long spirals, which is applied in excavation, foundation structure engineering, construction, etc., can solve the problems of restriction, mixing of sand layers or sand and pebble layers that cannot be implemented, and can achieve reliable water stop and protection of groundwater resources , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Construction preparation

[0024] 1) Collect data, do a good job of on-site survey, and carefully write the construction organization design;

[0025] 2) Clean up the underground and ground obstacles on the construction site, level the site, arrange site facilities reasonably, and ensure normal construction.

[0026] 3) Preparation of raw materials:

[0027] (1) All materials used shall comply with the design, national standards and landmark regulations;

[0028] (2) Cement must have a quality certificate from the factory, and its type, label, packaging, date of delivery, etc. should be checked and accepted when purchasing, and stored in accordance with relevant regulations; every 200 tons of cement supplied must be sampled for inspection. Take a small amount of samples from each of the 10 bags for inspection. H-shaped steel must provide factory quality certificate.

[0029] (3) A 15T crawler crane is used for the joint welding of section steel. The method adop...

Embodiment 2

[0060] 1. Project overview

[0061] The proposed Shunyi District labor training base and e-government center project is located on the north side of the North Second Ring Road, Shunyi District, Beijing, with a foundation buried depth of about 4.15-9.85m.

[0062] 2. Engineering hydrogeological conditions

[0063] The proposed site belongs to the middle and upper part of the alluvial fan of Chaobai River. The terrain of the site is basically flat, and the ground elevation of the borehole is 27.46-30.06m. The strata within the scope of drilling depth (35.00m) in this survey are divided into artificial accumulation layer and Quaternary sedimentary layer according to genetic type and depositional age. Now it is described from top to bottom as follows:

[0064] Artificial fill layer

[0065] a. Silt fill ①: yellowish brown, slightly wet, slightly dense, partially containing more ash, bricks and other building waste and domestic waste. The thickness of this layer is 0.50-3.00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com