Ultra-thin heat insulation composite insulation board and cast-in-place concrete composite wall and construction method

A composite thermal insulation and composite wall technology, applied in thermal insulation, chemical instruments and methods, walls, etc., can solve the problems of inability to guarantee the service life of the thermal insulation system, increase the workload, and low work efficiency, and achieve good economic and social benefits. , Simple construction and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

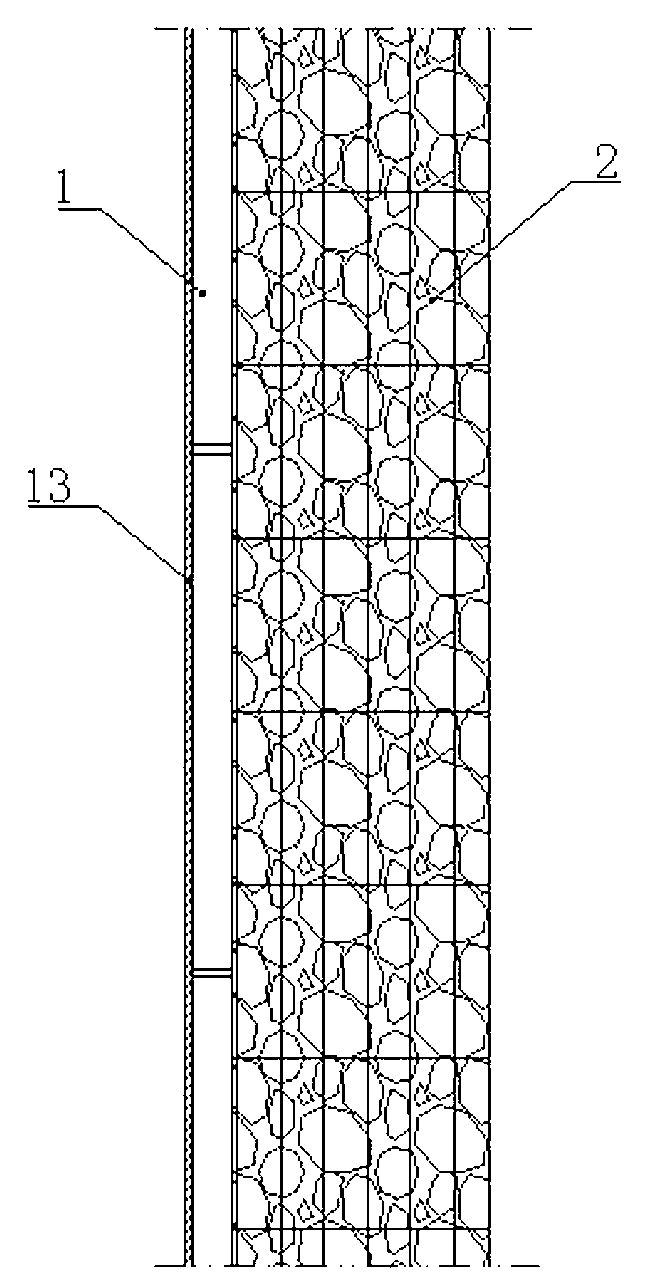

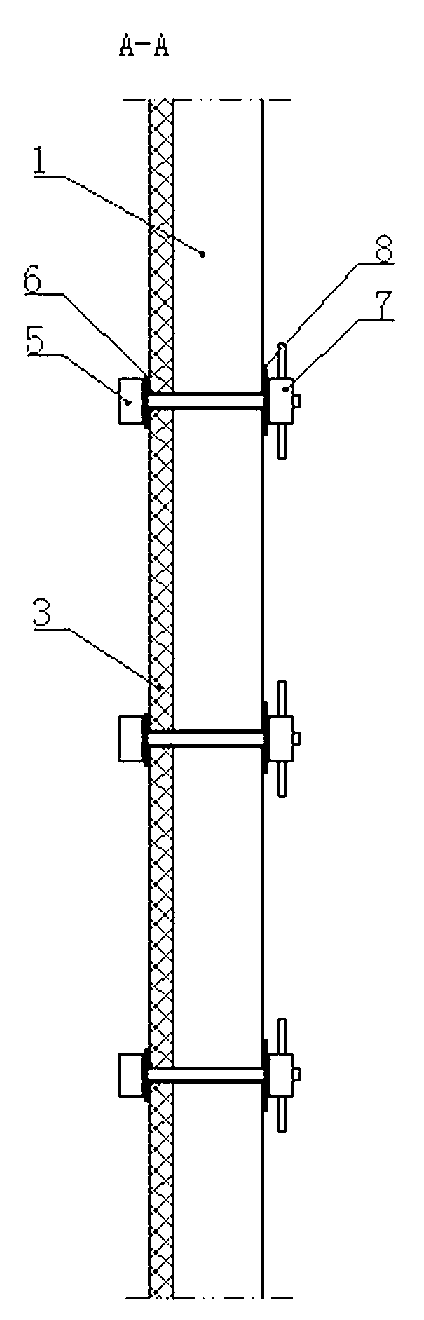

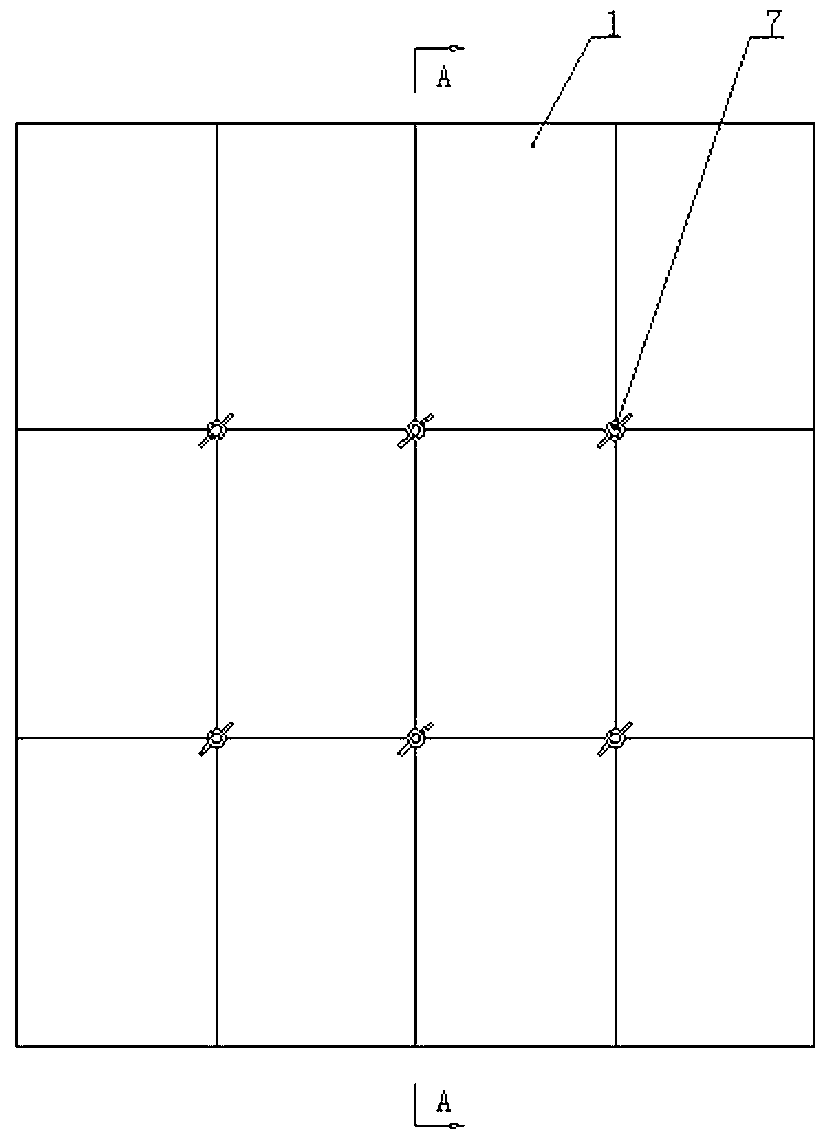

[0034] see figure 1 , the present invention is a composite wall of ultra-thin heat-insulating composite thermal insulation board and cast-in-place concrete, which is characterized in that it includes an ultra-thin thermal-insulation composite thermal insulation board 1, a reinforced concrete wall 2 and a facing layer 13, and the cast-in-place reinforced concrete wall The body 2 is bonded together with the outer ultra-thin heat-insulating composite heat-insulation board 1 , and the outer side of the ultra-thin heat-insulation composite heat-insulation board 1 is provided with a facing layer 13 .

[0035] The concrete strength of the reinforced concrete wall body 2 is C20 or above.

[0036] The cement used in the concrete is Portland cement, aluminate cement, sulphoaluminate cement, iron-aluminate cement, magnesia cement, and high-strength gypsum, or a mixture of several in any proportion. .

[0037] A protective layer with a thickness of 2-25 mm is coated on the periphery of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com