Labyrinth Piston Ring

A piston ring and labyrinth technology, applied in the field of piston rings, can solve the problems of environmental pollution, low economic benefits, affecting the sealing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

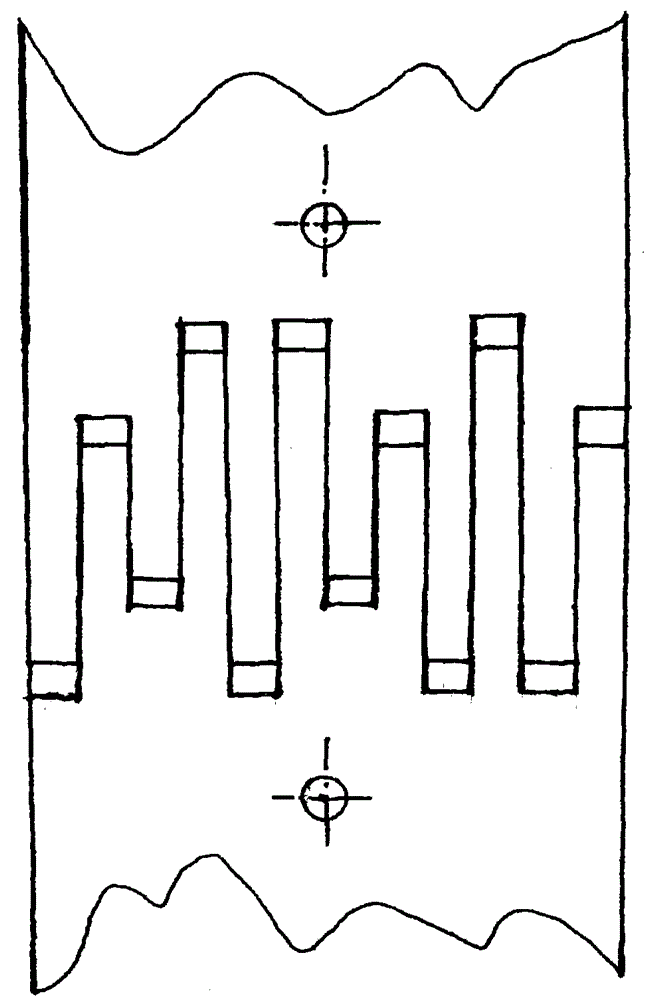

[0005] A kind of labyrinth piston ring, the two ends of the opening of the outer ring surface of the piston ring are symmetrical and evenly distributed with two small blind holes of equal size, which are used for the installation of the piston ring; the sealing of the opening of the piston ring is based on the teeth In the way of meshing with the teeth, the radial meshing gap between the teeth at both ends of the piston ring is equal to the gap at the opening of the piston ring, and the radial meshing gap between the teeth at both ends of the piston ring is much larger than that between the teeth at both ends of the piston ring. The circumferential meshing clearance of the piston ring teeth can be of equal height and width or equal height and unequal width or unequal height and width or unequal height and unequal width. The radial meshing clearance between the teeth and teeth at both ends of the piston ring is equal in size. If conditions permit, the more meshing teeth the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com