High-temperature sealing type two-lug support plate self-locking nut

A high-temperature sealing and self-locking nut technology, applied to nuts, screws, bolts, etc., can solve the problems of poor high and low temperature resistance, achieve good vibration resistance, improve installation reliability, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

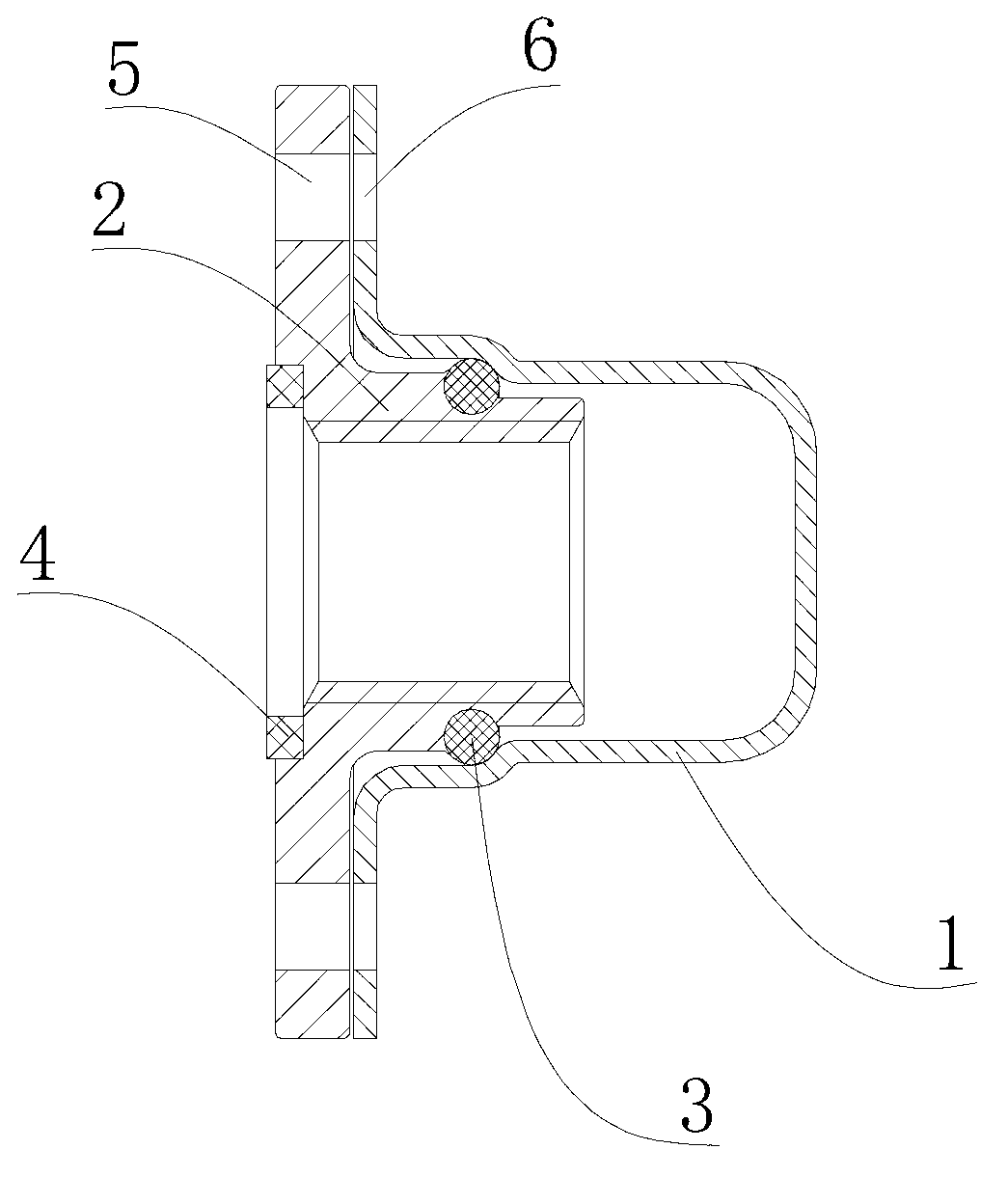

[0022] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

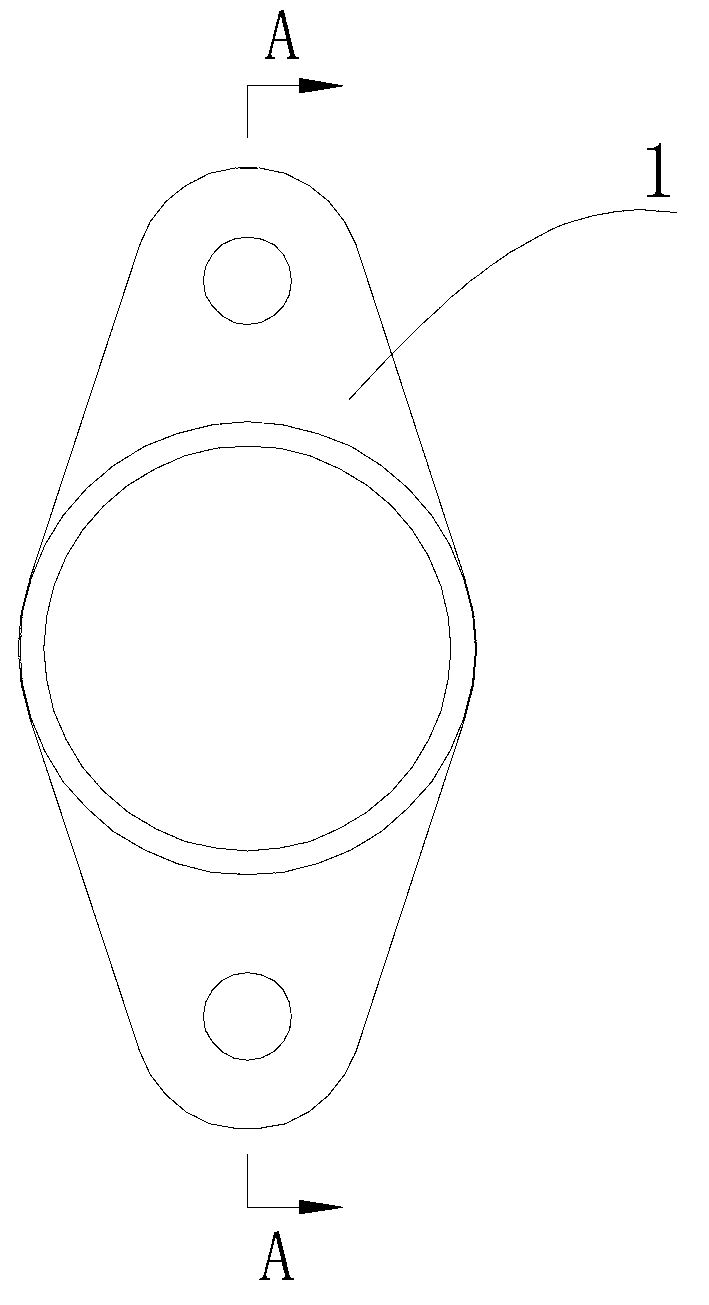

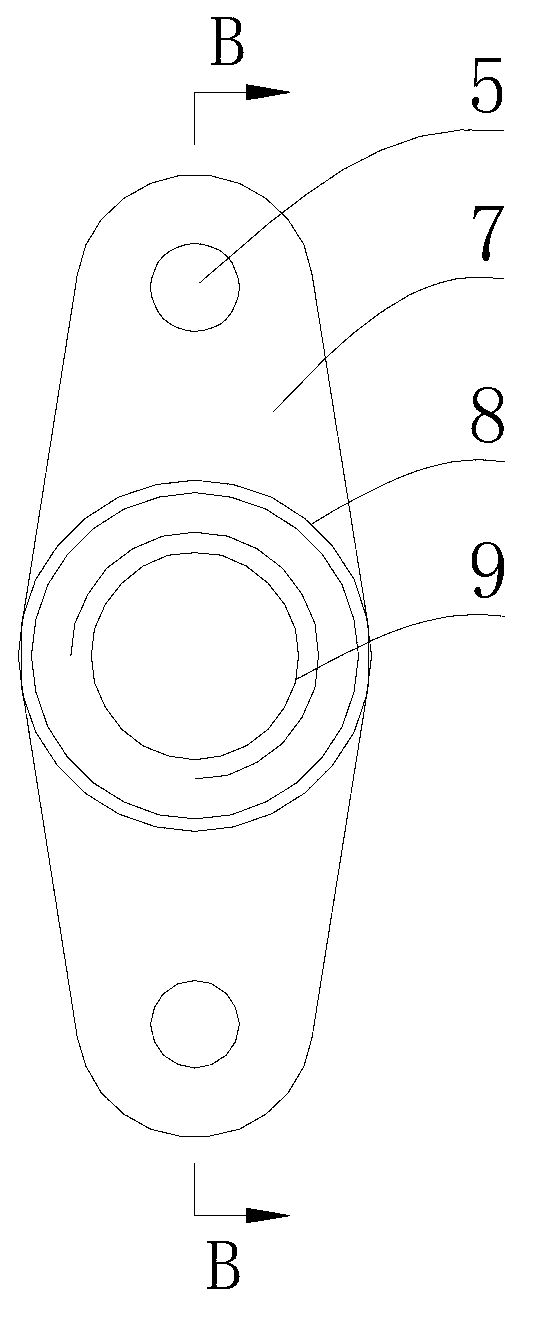

[0023] like Figure 1 to Figure 5 As shown, a high-temperature sealed double-eared self-locking nut includes a nut body 2 and a sealing cover 1 placed outside the nut body 2. The nut body 2 includes a supporting plate 7, a closing section 8 and a nut body 2 The internal thread 9 is provided with a sealing gasket 4 at the bottom of the supporting plate 7, and a sealing ring 3 is set on the outside of the closing section 8.

[0024] The bottom of the supporting plate 7 is provided with a groove 12 for installing the gasket 4 .

[0025] A lower annular groove 10 for installing a sealing ring 3 is provided on the outside of the closing section 8 .

[0026] An upper annular groove 11 matching the outer diameter of the sealing ring 3 is provided inside the sealing cover 1 corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com