Smart pipeline with optical fiber sensing function and manufacturing method for smart pipeline

A technology of intelligent pipes and manufacturing methods, applied in the directions of hoses, pipes, rigid pipes, etc., can solve problems such as damage to sensing optical cables, poor durability of optical cables, false alarms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with drawings and embodiments.

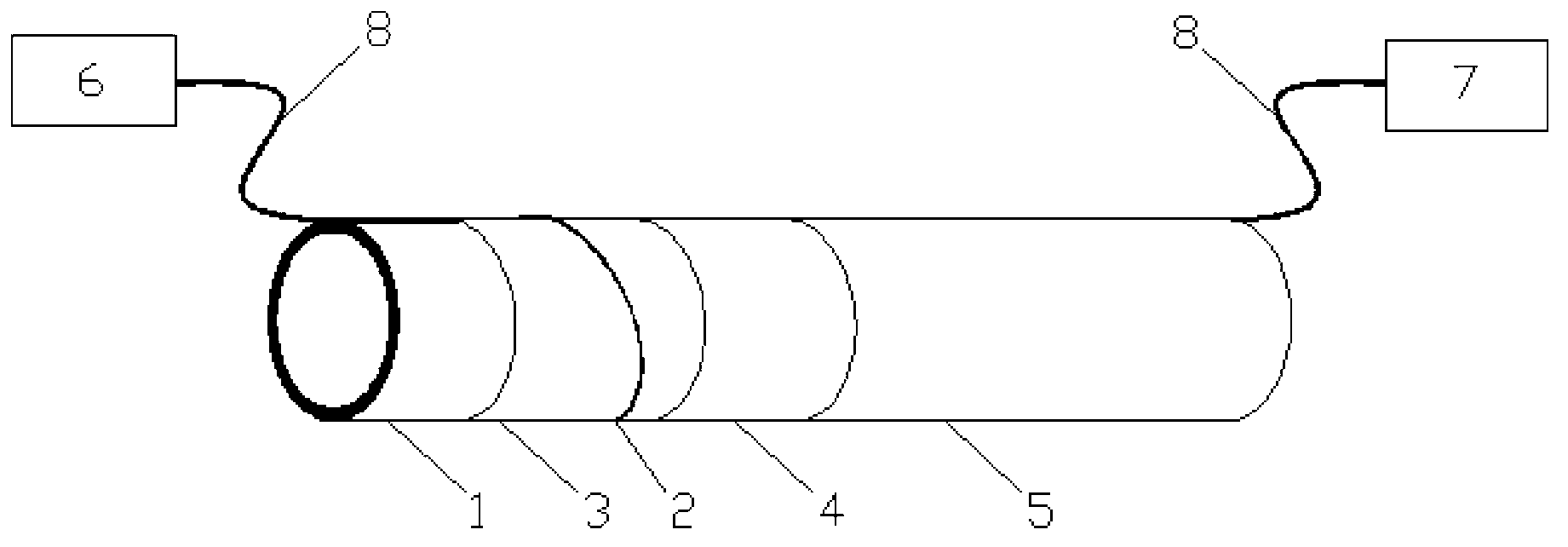

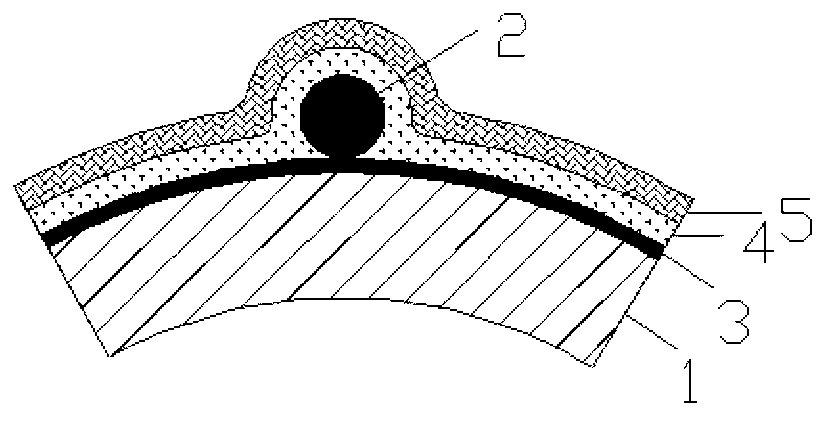

[0045] The basic idea of the present invention is to integrate the laying of sensing optical cables that meet different monitoring and detection requirements into the 3PE anti-corrosion processing technology of pipelines. A smart pipeline with structure and sensing optical cable integrated. After the pipeline is put into use, it is connected with additional components, and one or more parameters such as temperature, stress, vibration, etc. of the pipeline structure itself or the surrounding environment are monitored through the sensor optical cable, so as to realize real-time pipeline leakage, corrosion, third-party interference, etc. Online Monitoring.

[0046] 1. Intelligent pipeline structure with optical fiber sensing function

[0047] 1) The intelligent pipeline structure with optical fiber sensing function is composed of the following basic components: pipelin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com