Device and method for measuring liquid jet on outermost boundary

A liquid jet and measurement device technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve problems such as uneven distribution of gray scale, uneven distribution of droplet concentration, human factors and large uncertainties, and achieve physical well-defined effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

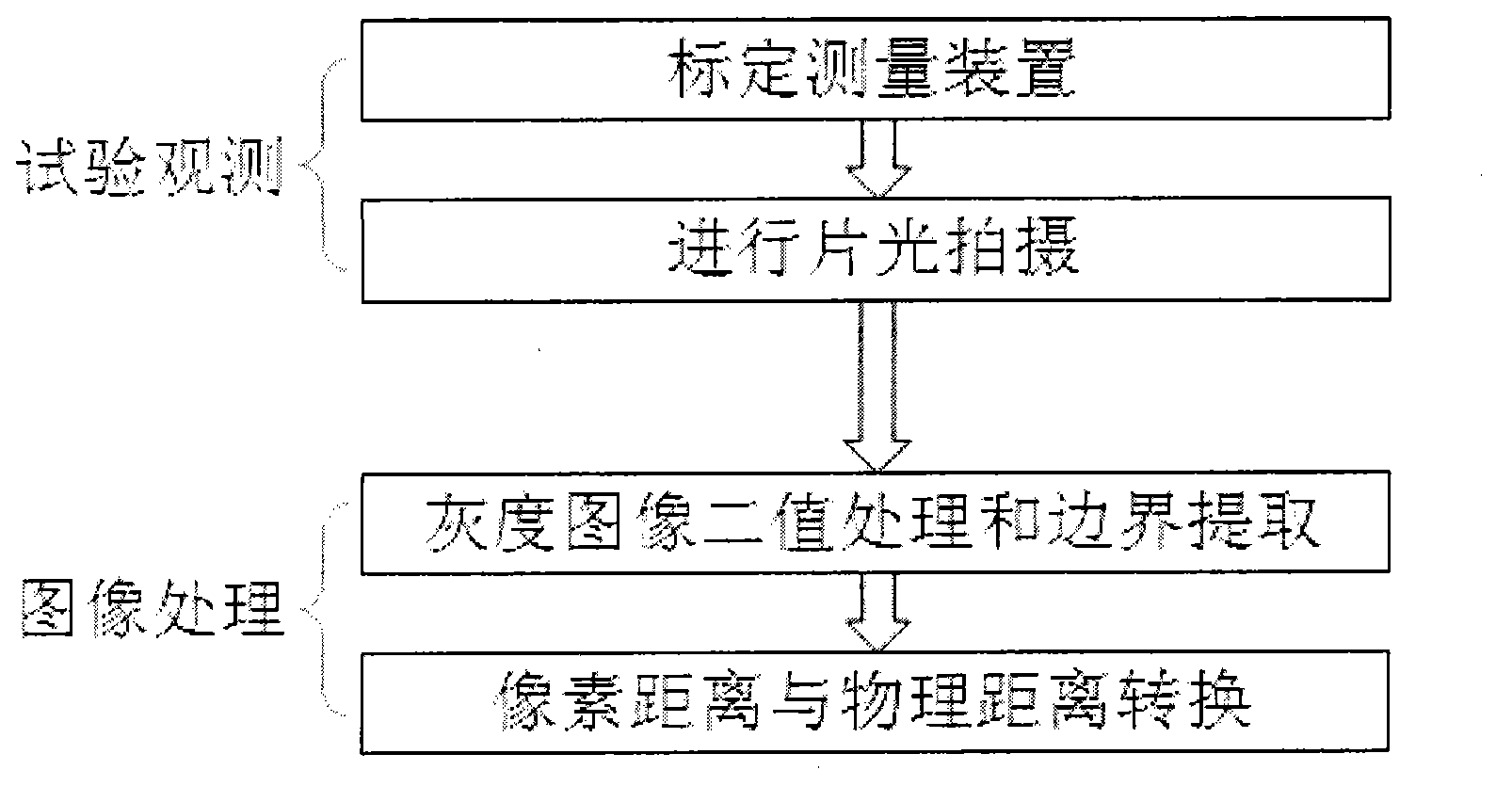

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

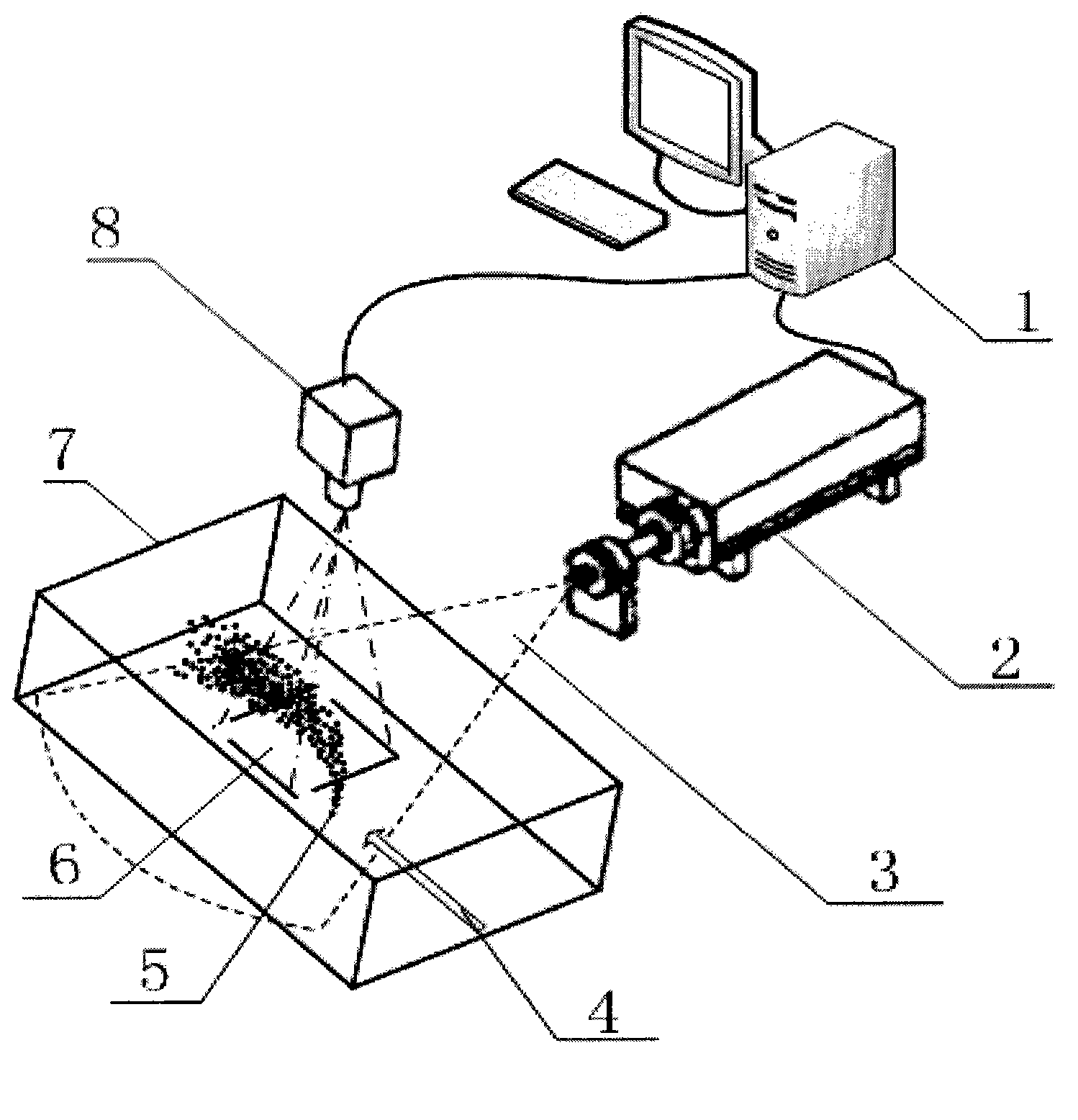

[0025] This embodiment is a measuring device for the outermost boundary of a liquid jet, and its structural schematic diagram is as follows figure 2 shown. Including computer 1, camera 8, test section 7, laser generator 2.

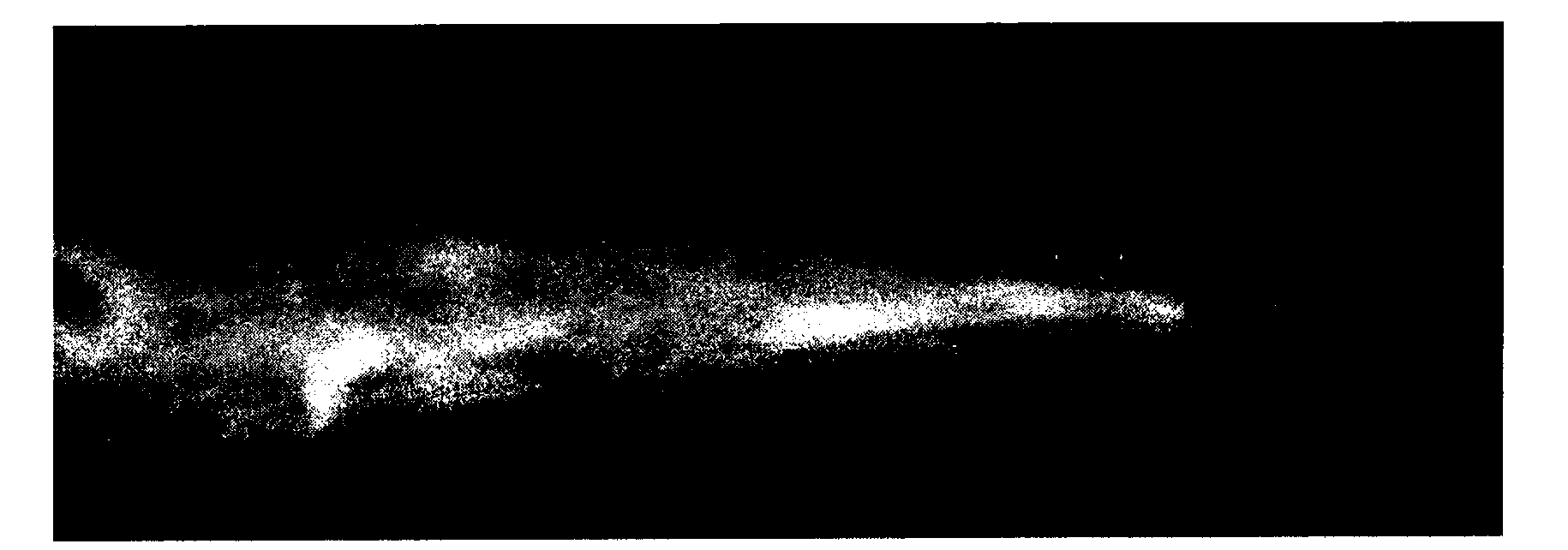

[0026] The jet is ejected from the bottom of the test section 7, deflected, broken, and atomized into small droplets under the action of the airflow 4, and the camera 8 is used to photograph the small droplets; the laser generator 2 emits laser light 3 to irradiate the small droplets , the focal plane 6 of the camera 8, the laser sheet light 3 and the plane to be observed are in the same plane. The shooting surface of the camera 8 corresponding to the test section 7 and the incident surface of the laser sheet light 3 are transparent, and the other surfaces are painted black to maintain the darkroom environment of the laboratory, prevent the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com