High-speed loading material dynamic indentation experimental method

A technology of dynamic indentation and experimental methods, which is applied in the direction of testing material hardness, etc., can solve the problems that the dynamic mechanical properties of materials cannot be measured, and the dynamic mechanical properties of materials cannot be measured, and achieve simple data processing methods and high measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

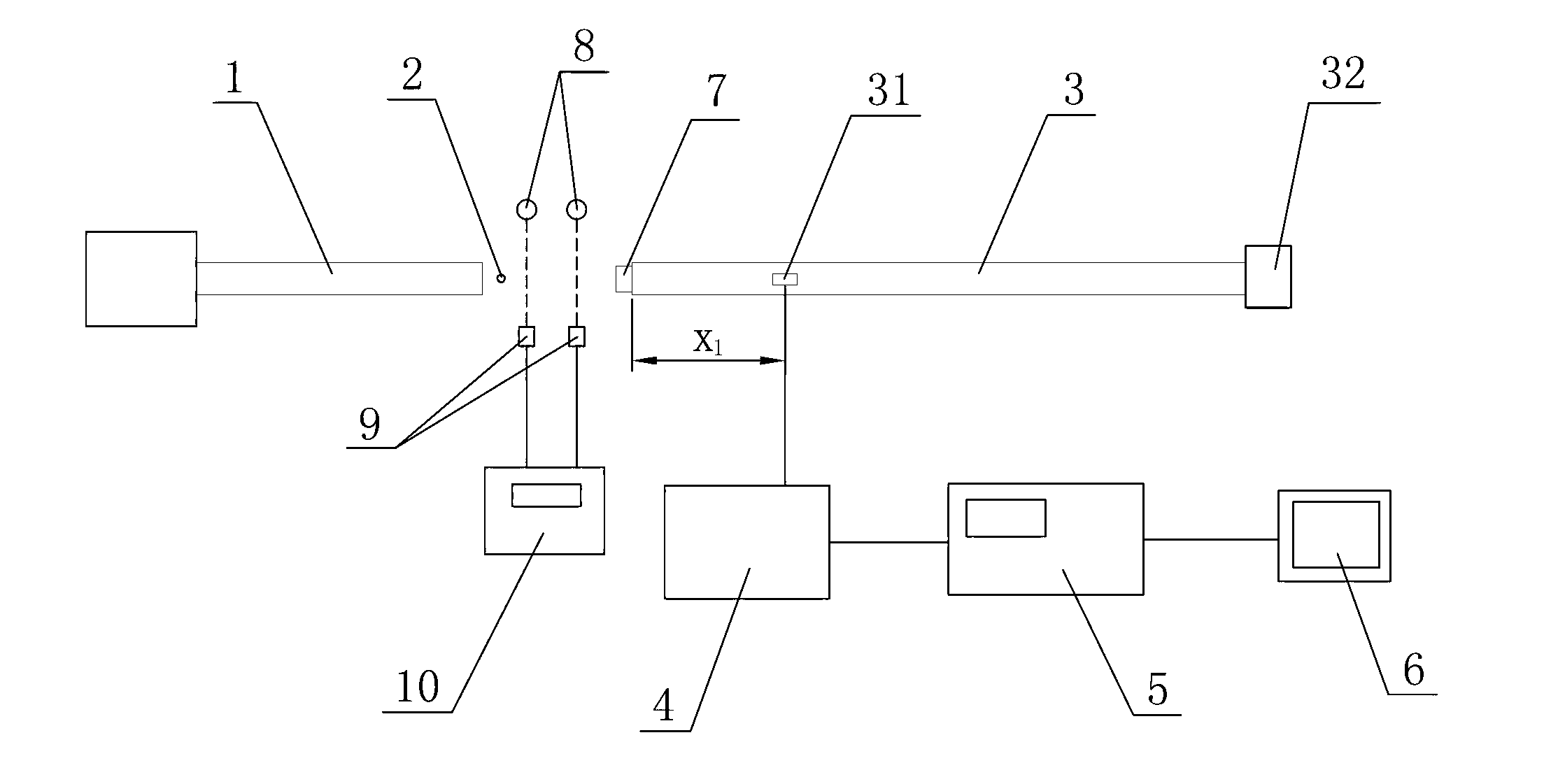

[0026] As shown in the figure, a high-speed loading material dynamic indentation test method includes the following specific steps:

[0027] (1), at the front end face of circular section pressure bar 3 fixedly arrange cylindrical tested piece 7, and make the radius of tested piece 7 slightly less than the radius of pressure bar 3;

[0028] (2), stick strain gage 31 on depression bar 3, and strain gage 31 is electrically connected with ultra-dynamic strain gauge 4, super-dynamic strain gauge 4 and computer processing system 6 are electrically connected with digital oscilloscope 5 respectively, then press The tail end of the rod 3 is fixedly provided with an energy-absorbing block 32 whose material is lead;

[0029] (3), light-triggered speed-measuring device is fixedly installed in front of tested piece 7, and light-triggered speed-measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com