Patents

Literature

44results about How to "The data processing method is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

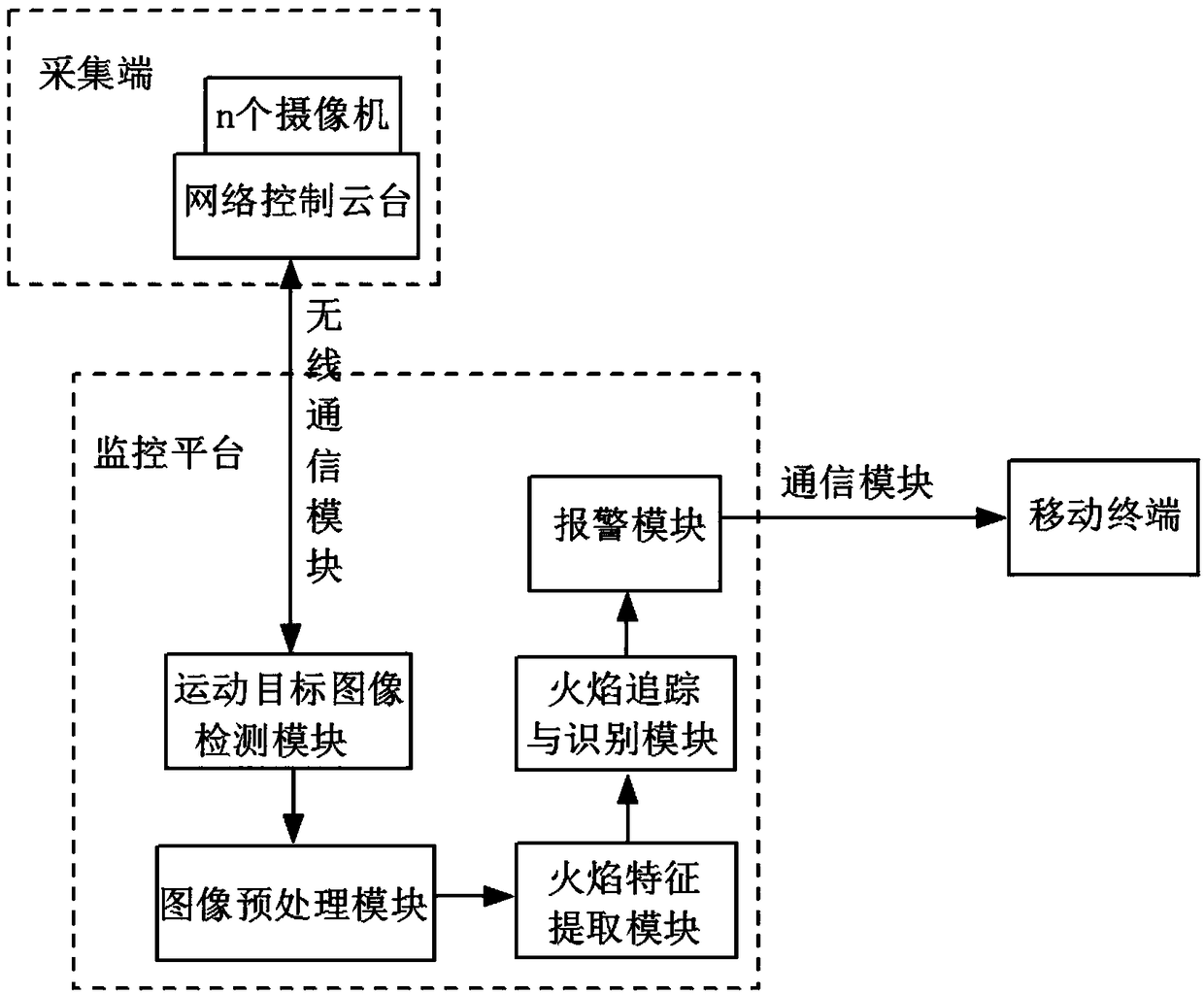

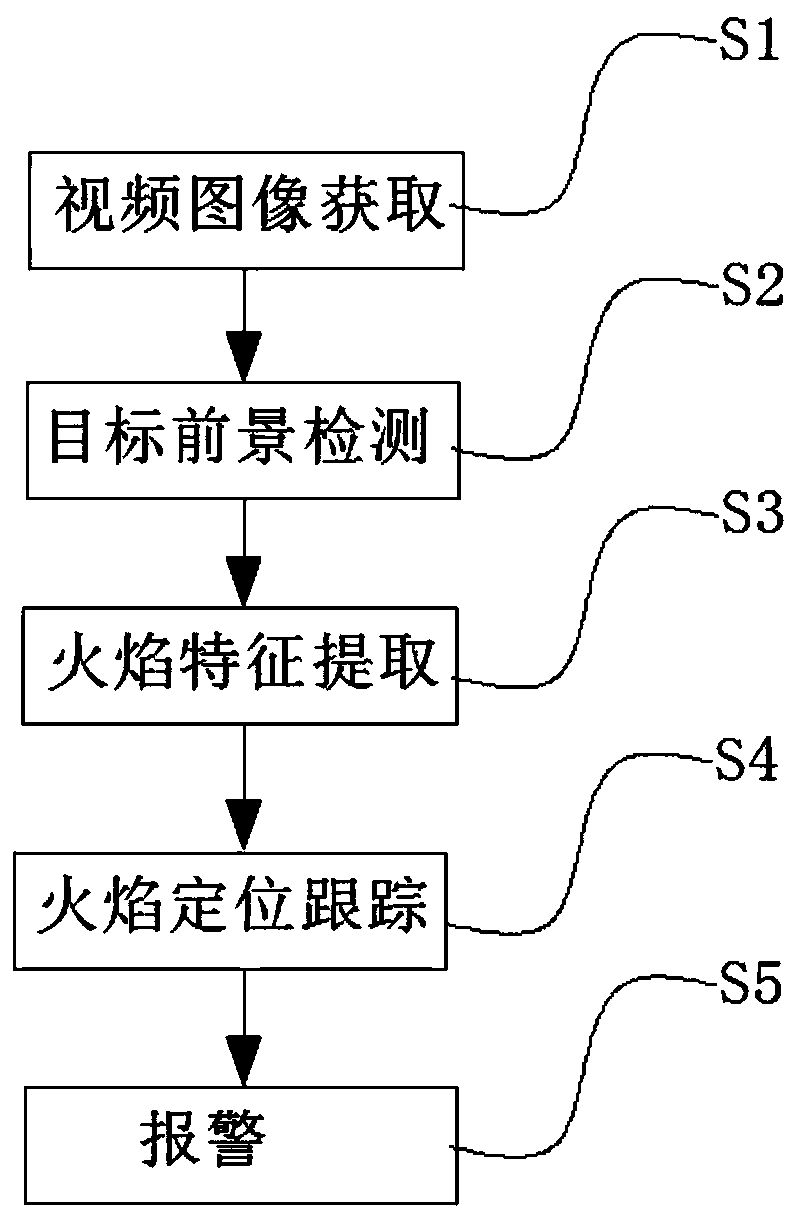

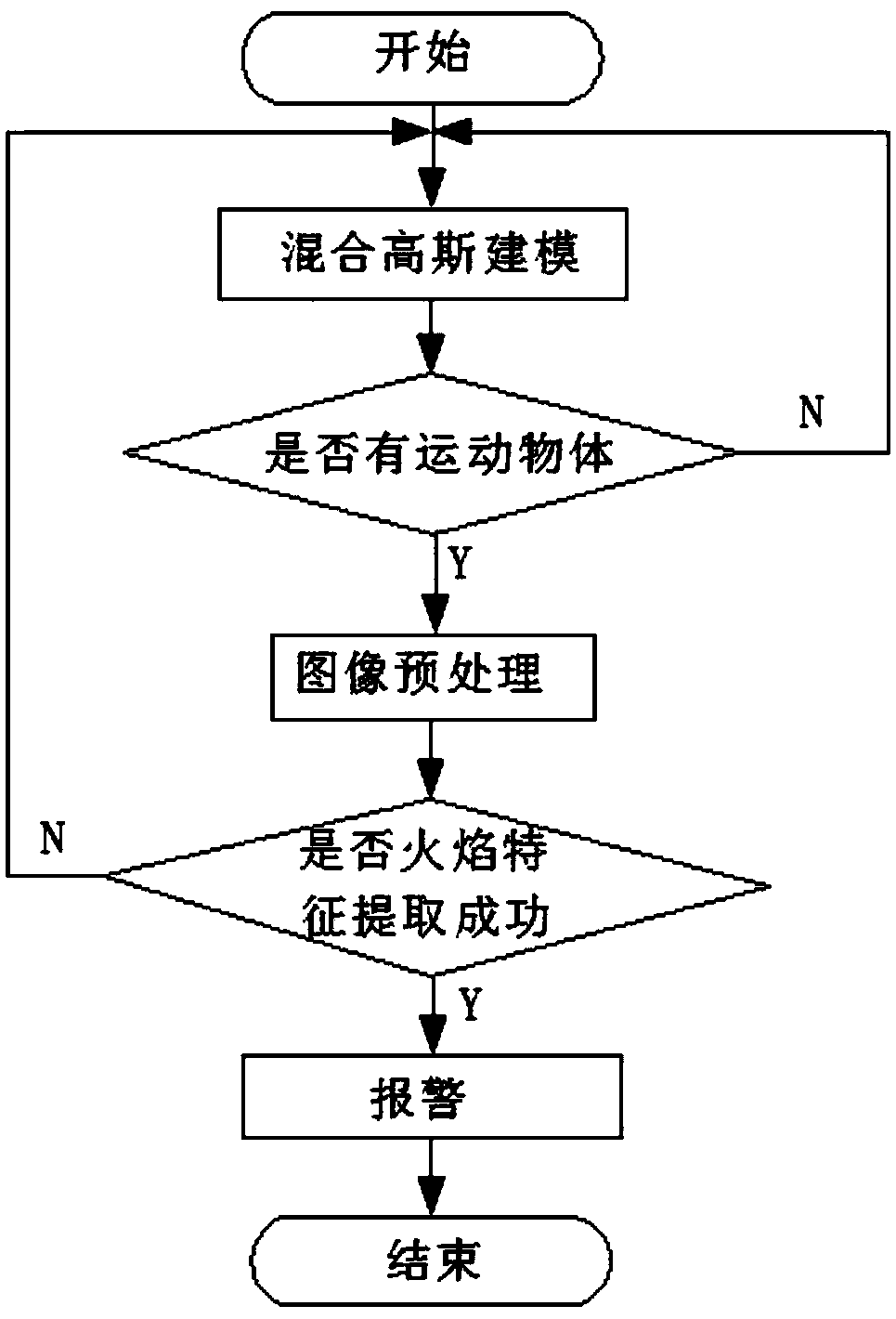

Machine vision based forest fire preventive early warning system and method thereof

InactiveCN109377703AAccurate Disaster Relief MeasuresAccurate trackingImage enhancementImage analysisEarly warning systemMachine vision

The invention discloses a machine vision based forest fire preventive early warning system and a method thereof. The system comprises a collection end and a monitoring platform composed of a movementtarget foreground detection module, a flame feature extraction module, a flame tracking and identification module and an alarm module, can monitor a fire hazard uninterruptedly in 24 hours, can identify occurrence of the fire hazard and track flame accurately, and emits a fire hazard early warning signal by the monitoring platform so that relates work staff can take measures accurately, and the system is high in practicality. A Gaussian mixture background model is sued when video images are detected to identify whether there are moving objects in the video images, a modeling algorithm is complete, targets can be extracted from videos effectively, the fire hazard identification rate can reach more than 92%, and the fire hazard identification accuracy can be improved substantially.

Owner:HECHI UNIV

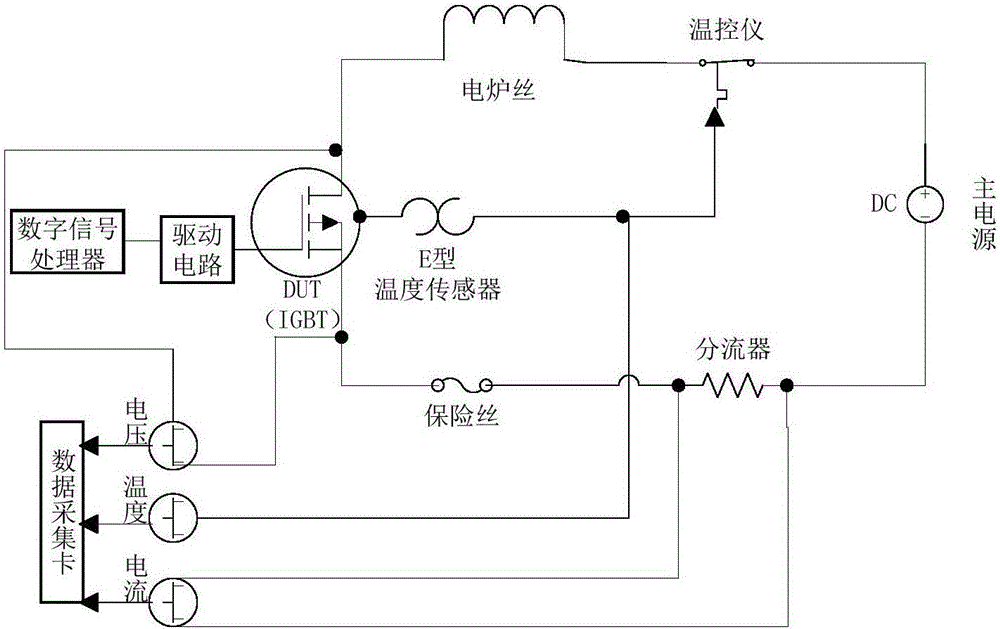

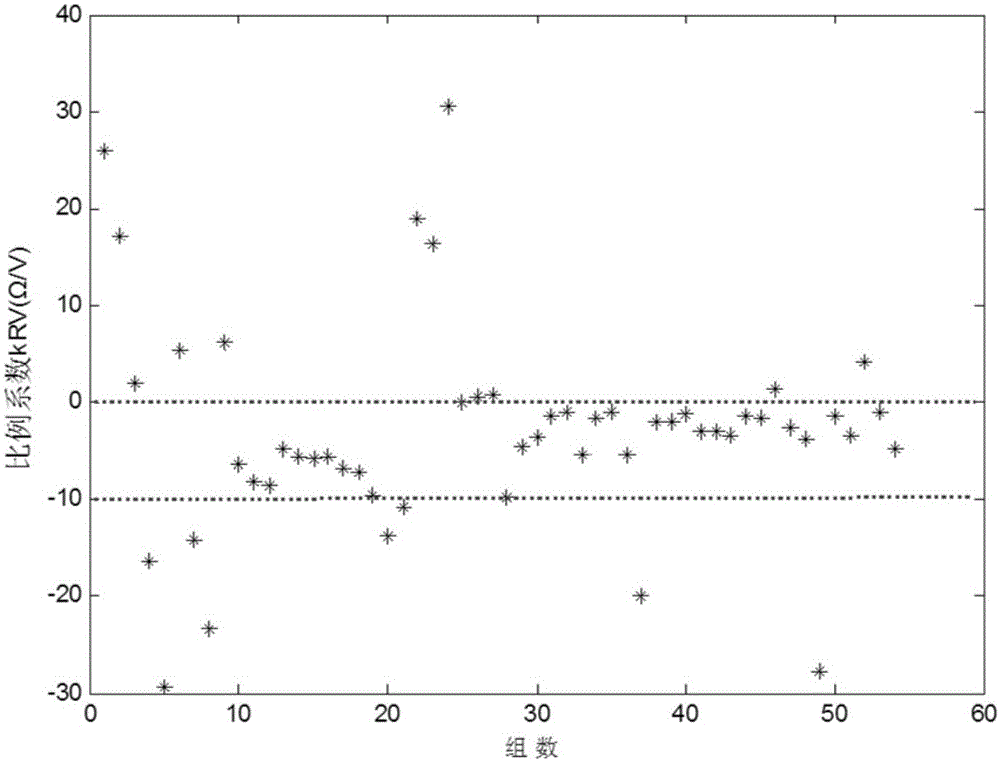

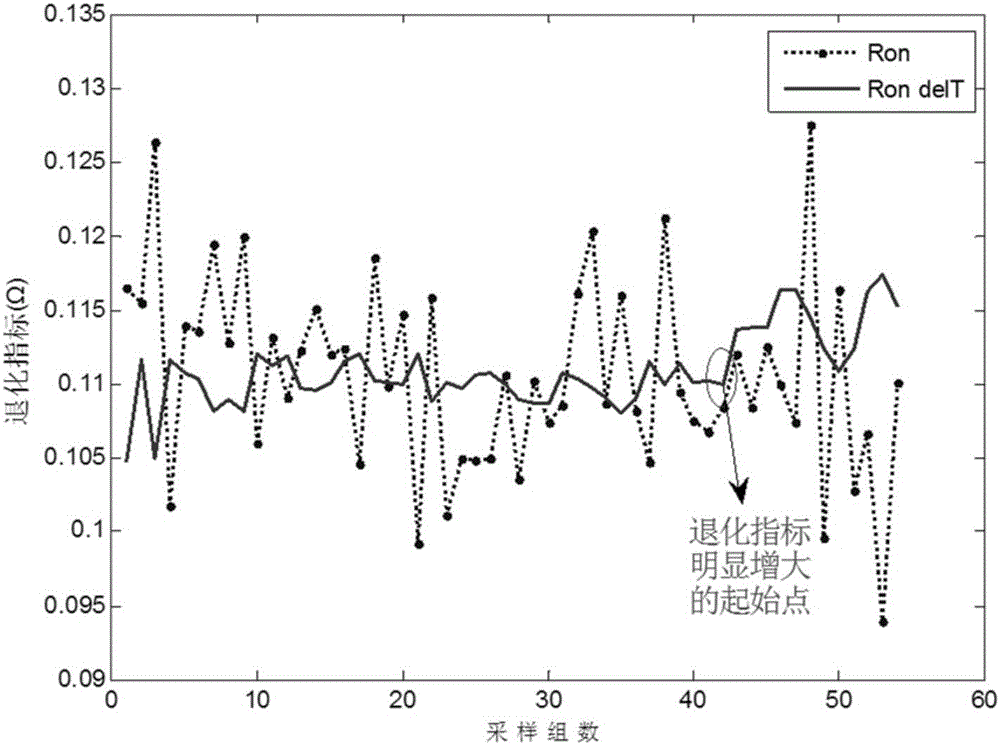

Online monitoring method for degradation of insulated gate bipolar transistor

ActiveCN106124957AAddress reliabilityEasy to operateBipolar transistor testingVoltage dropJunction temperature

The invention discloses an online monitoring method for degradation of an insulated gate bipolar transistor (IGBT). The online monitoring method can be used for monitoring the degradation degree of the IGBT in actual operating process, so as to send out early warning before the IGBT fails. The online monitoring method comprises the steps of: under the condition that the IGBT does not degrade, conducting a temperature experiment on an IGBT to be monitored, measuring junction temperature indexes (invariant voltage drop) representing IGBT junction temperature levels at different junction temperatures of the IGBT to be monitored and degradation indexes (conductive resistance) representing IGBT degradation degrees, and calculating a proportionality coefficient of degradation index variable quantity and junction temperature index variable quantity under the same junction temperature variation; and under the condition that the IGBT degrades, measuring a junction temperature index and a degradation index online, carrying out optimization of removing junction temperature influence on the degradation index by combining with the proportionality coefficient obtained through the temperature experiment under the normal condition, and monitoring the degradation degree of the IGBT to be monitored according to the optimized degradation index.

Owner:ZHEJIANG UNIV +1

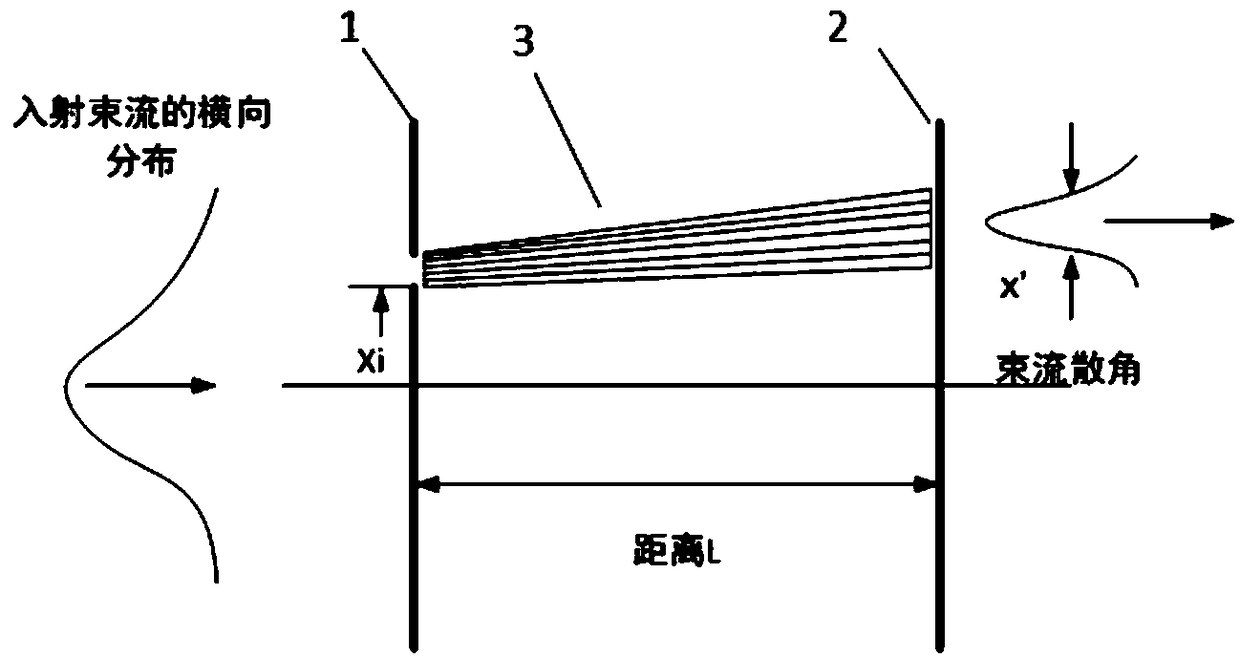

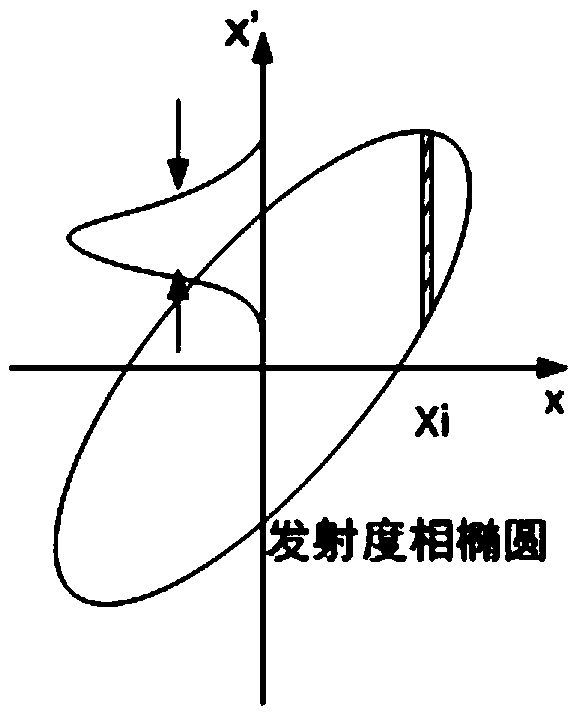

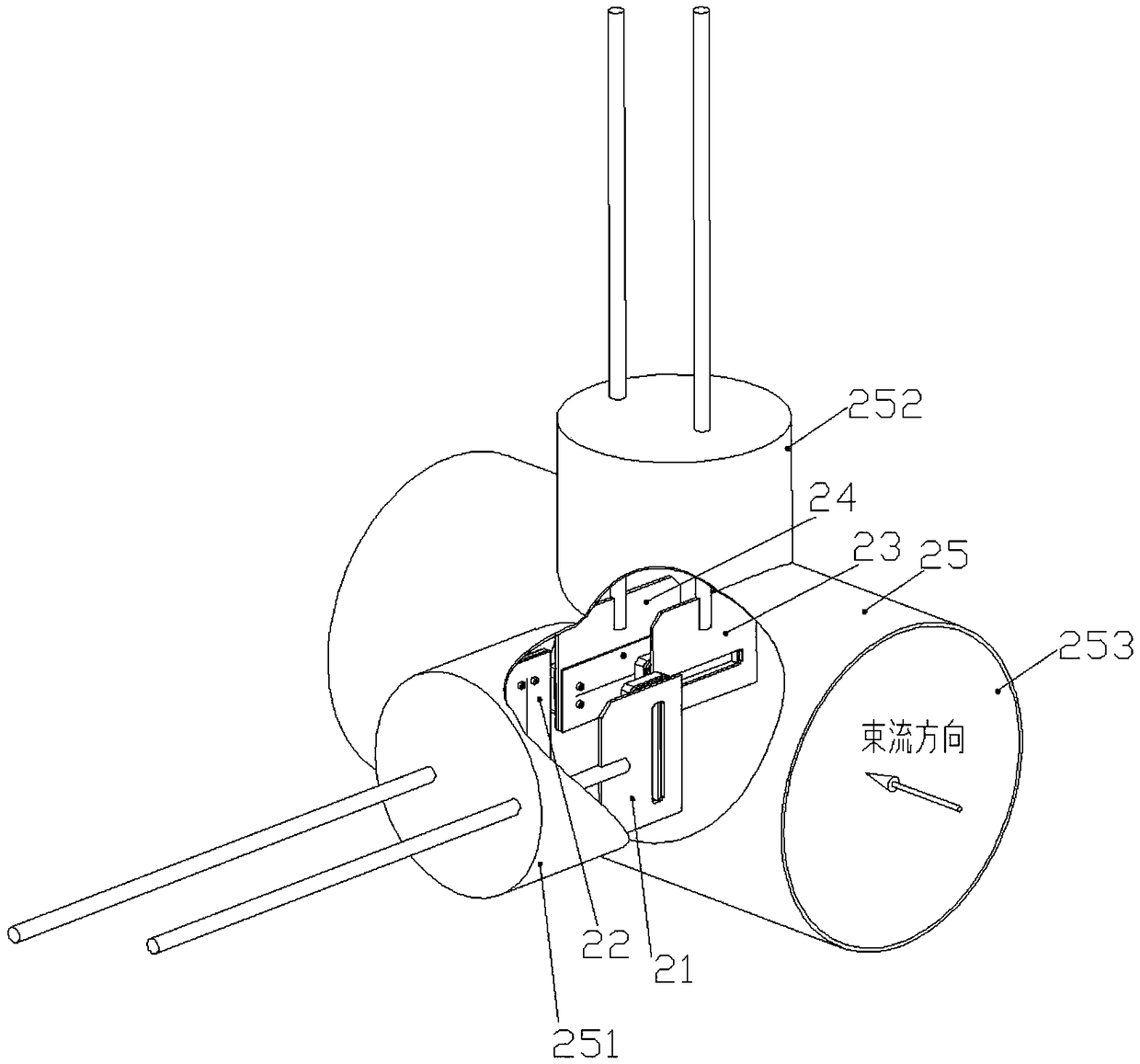

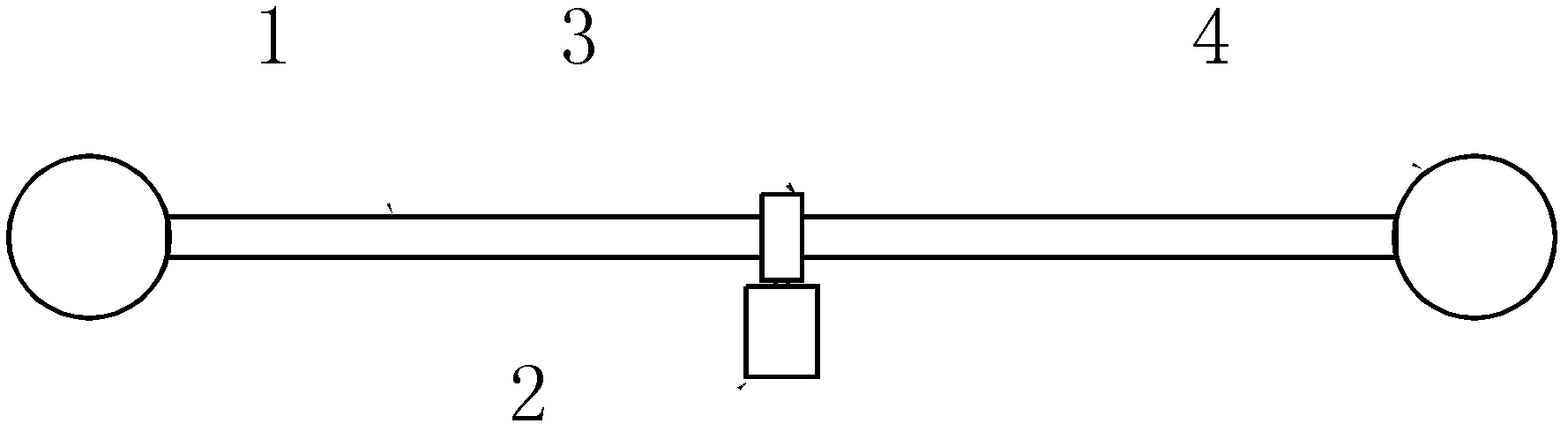

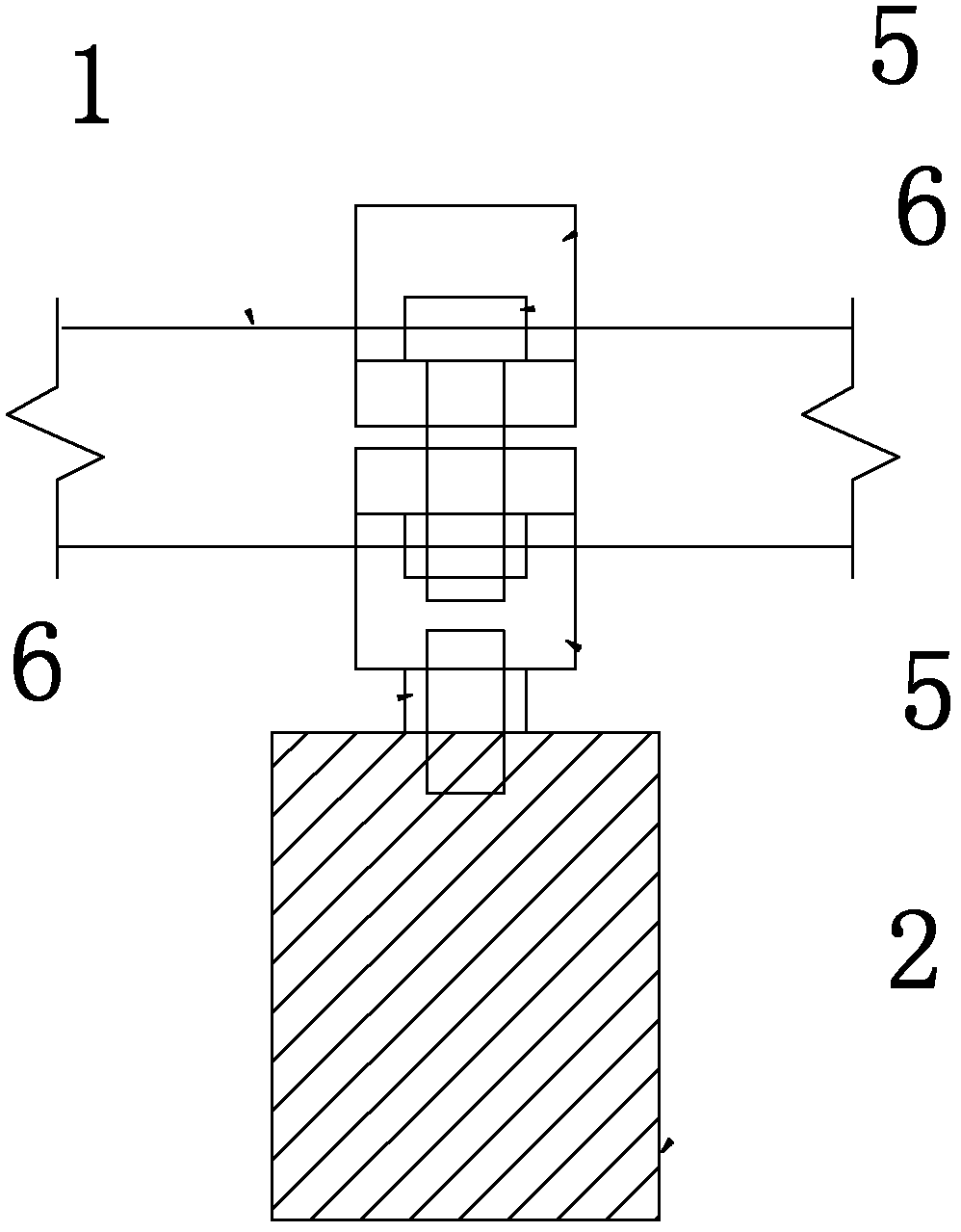

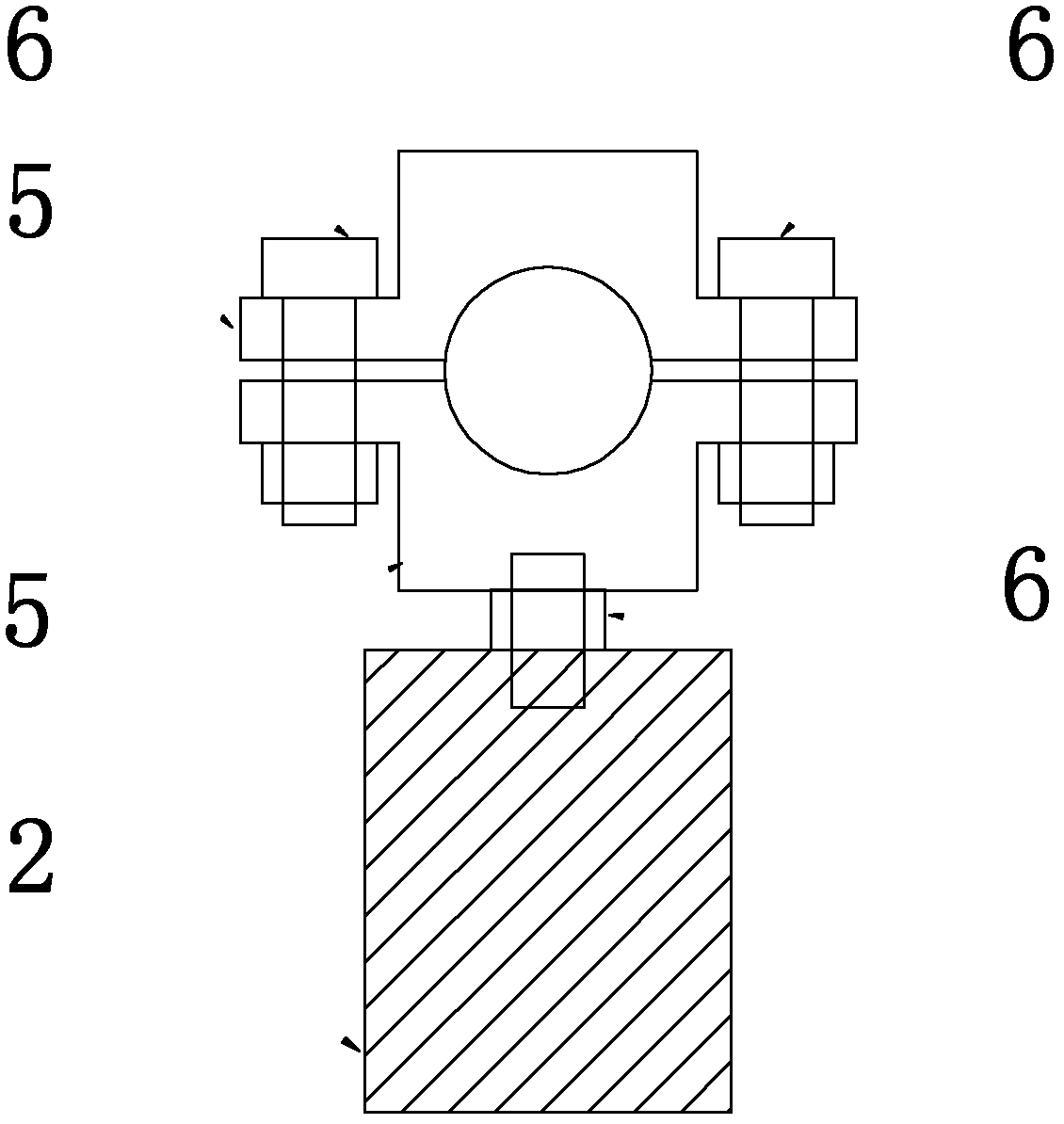

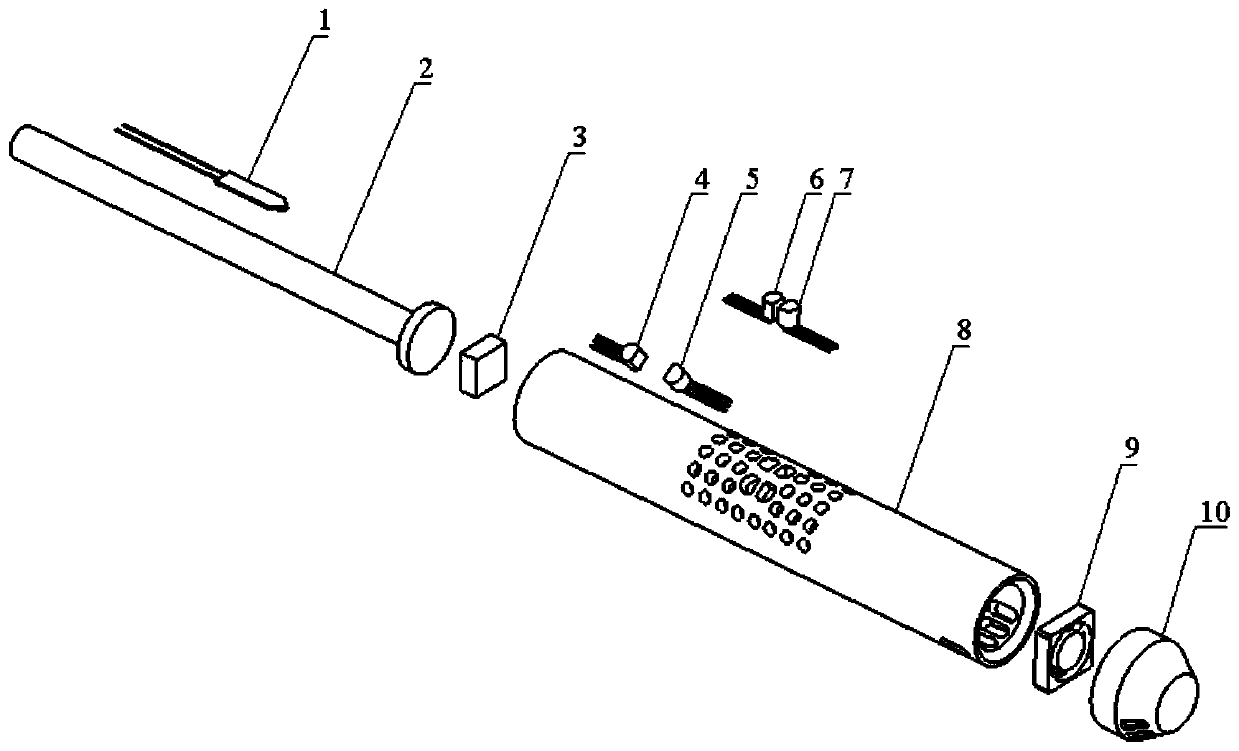

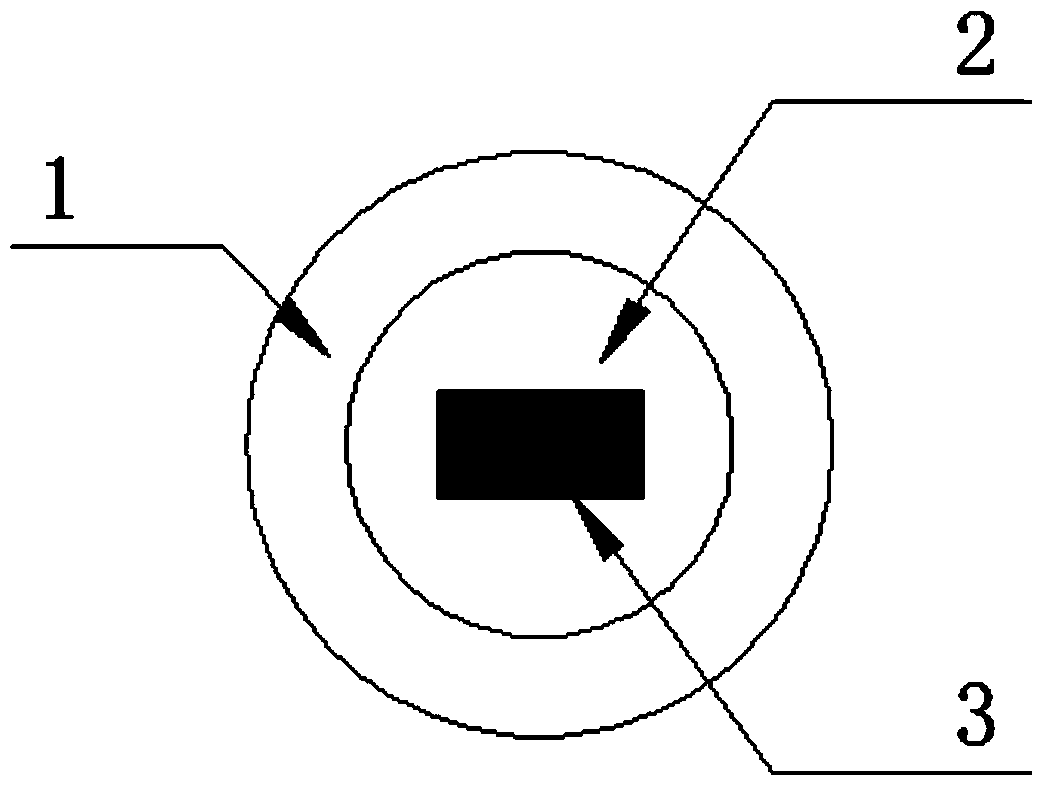

Device and method for simultaneously measuring beam intensity and beam emittance

InactiveCN108873051ACompact structureMiniaturizationX/gamma/cosmic radiation measurmentParticle beamMiniaturization

The invention relates to a device and method for simultaneously measuring beam intensity and beam emittance. The device mainly comprises position sampling slit plates in a horizontal direction and a vertical direction, angle sampling slit plates in a horizontal direction and a vertical direction, and a vacuum system. During the measurement of beam intensity, the intensity of an incident particle beam is obtained according to the sum of the currents received by Faraday cylinders at the position sampling slit plates, the angle sampling slit plates and Faraday cylinders behind the angle samplingslit plates. During the measurement of beam emittance, the position and the divergence angle of the beam are sampled under the driving of a motor, and the beam emittance is measured by measuring the positions of the two slit plates and a current signal received by the angle sampling slit plates. The device is compact in structure, easy to operate and easy to miniaturize, can measure the emittanceof the beam in both the horizontal and vertical directions, can also measure the intensity of the beam, is very suitable for the beam parameter measurement of a low-energy high-intense proton beam.

Owner:NORTHWEST INST OF NUCLEAR TECH

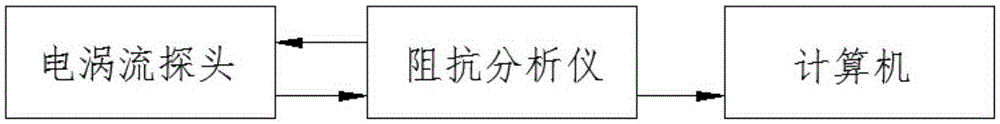

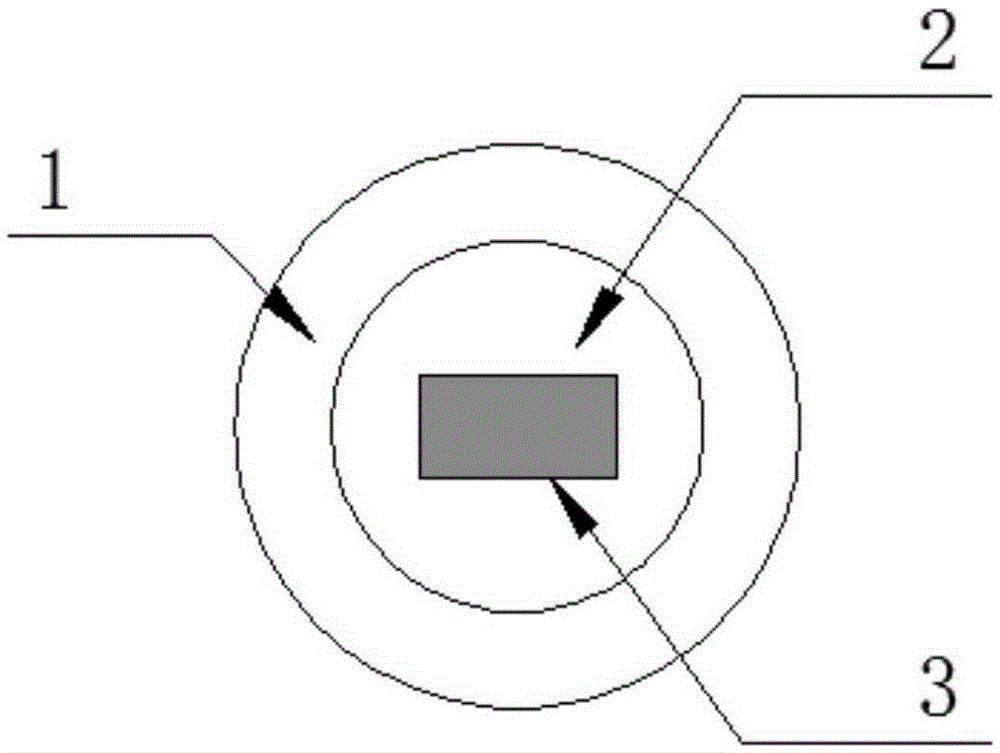

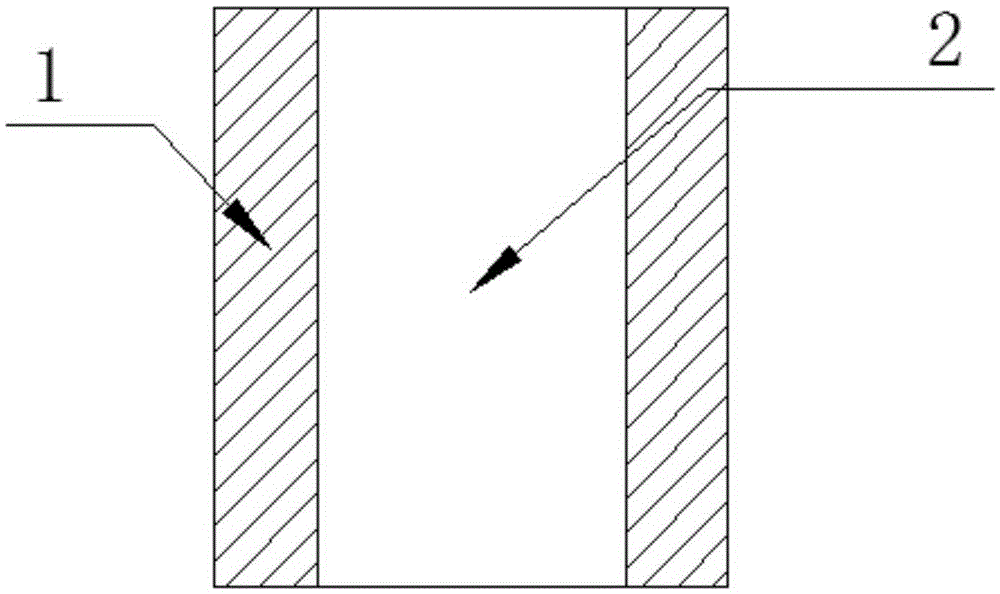

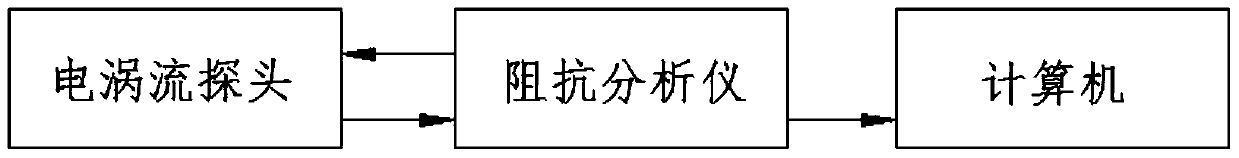

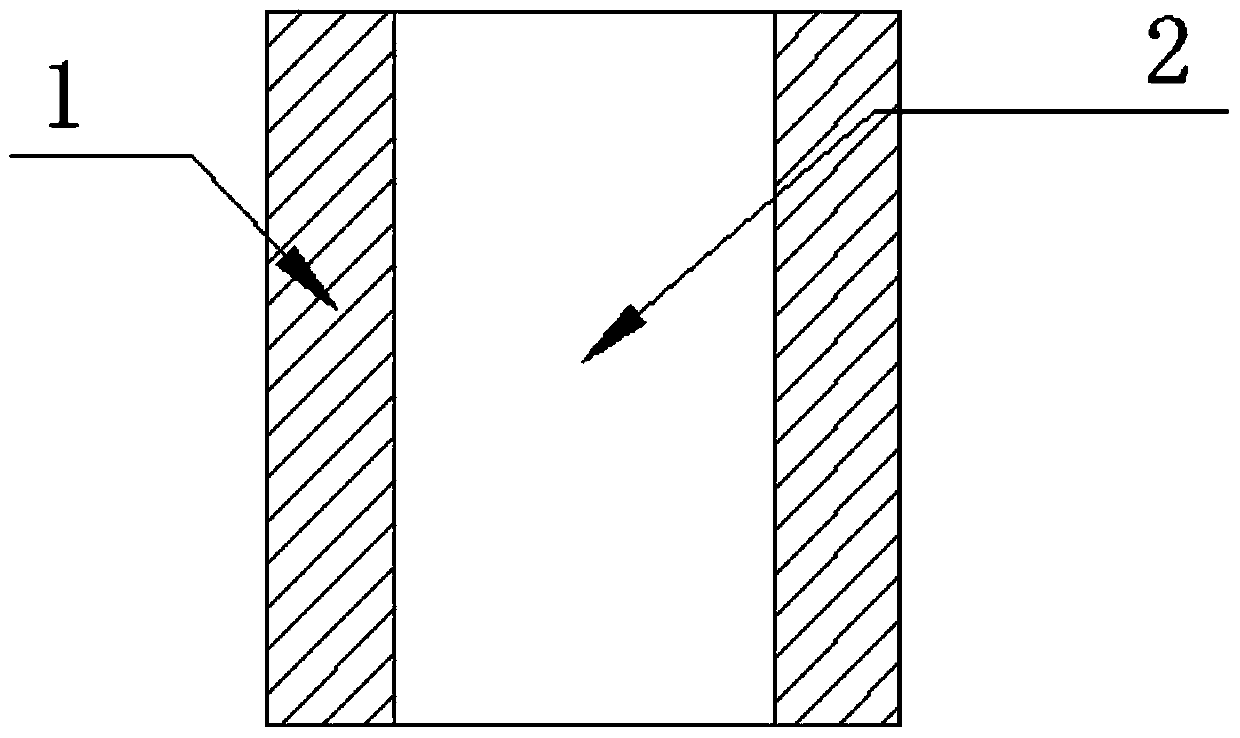

Eddy current detection device for automobile galvanized sheet plating thickness and method

InactiveCN105300266AHigh precisionAvoid measurement errorsElectrical/magnetic thickness measurementsElectricityEconomic benefits

The invention discloses an eddy current detection device for automobile galvanized sheet plating thickness and a method. The eddy current detection device disclosed by the invention comprises an eddy current probe, an impedance analyzer, a clamp used for fixing a member to be tested and a computer; the eddy current probe is placed on the surface of the member to be tested and is used for generating a sine excitation signal through the impedance analyzer, driving the eddy current probe to generate an excitation magnetic field and generating a vortex magnetic field inside the member to be tested; the probe converts the magnetic field change caused by the thickness change to an electric signal which is returned to the impedance analyzer to obtain an inductance according to the various vortex magnetic fields generated by the members to be tested with various plating thickness; the inductance is processed by a galvanized layer thickness model established by a computer to obtain the thickness of the galvanized layer of the member to be tested; the invention also discloses a detection method using the same. The invention chooses the inductance as the characteristic parameter for measuring the thickness, improves the range and the sensitivity of measuring the thickness, realizes the fast and accurate on-line detection for the thickness of the plating thickness of the galvanized sheet and has a substantial and potential economic benefit.

Owner:CHINA UNIV OF MINING & TECH

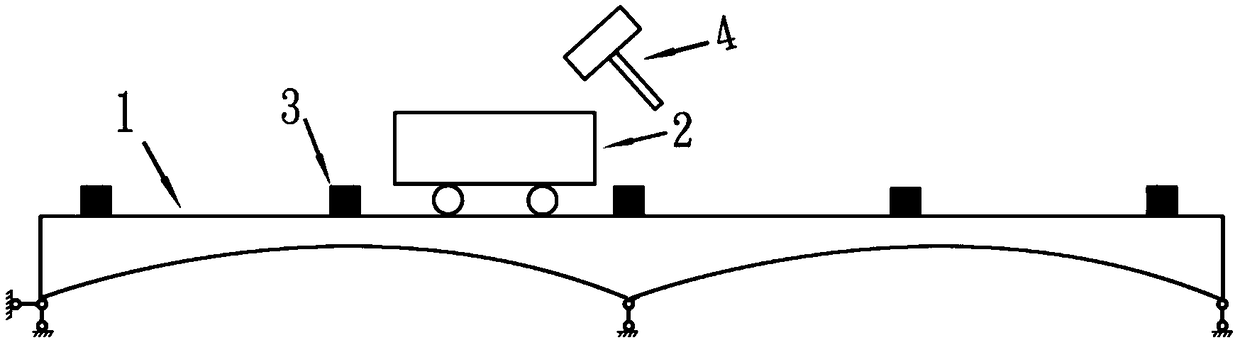

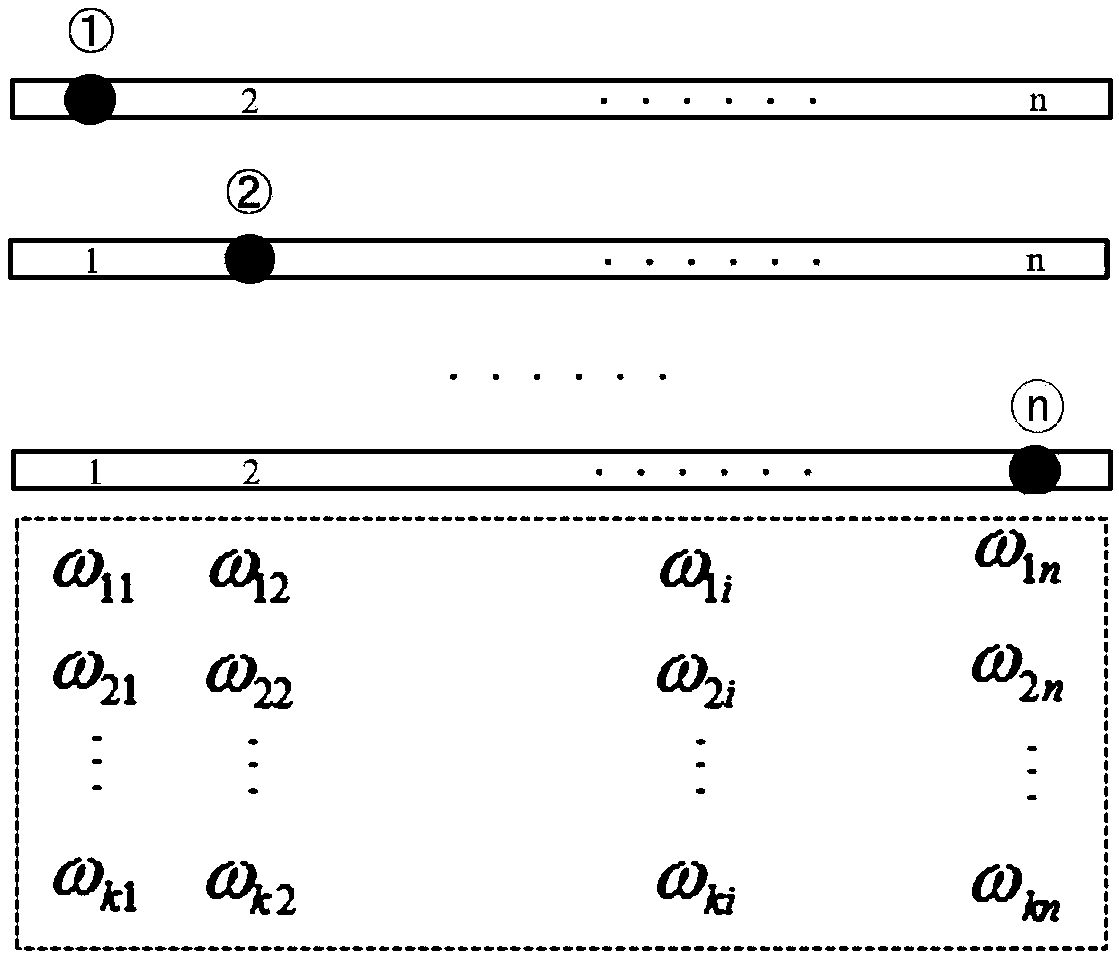

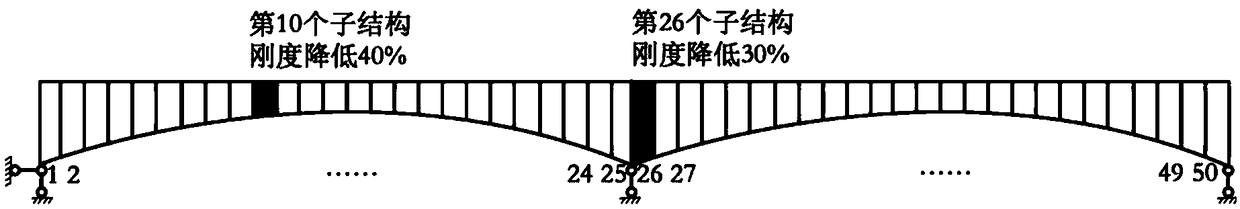

Damage positioning method of beam bridge structure based on mobile vehicle

The invention discloses the damage positioning method of a beam bridge structure based on a mobile vehicle and belongs to the structure damage identification calculating field. The vehicles are movedat the different positions of the beam bridge structure, and the vehicles are considered as mass and are added to the structure. Through continuously moving the vehicles along a bridge length direction, the inherent frequency of a mass-structure system is measured, and then, stationary wavelet analysis is performed on a frequency signal and the damage position of the structure is positioned. By using the method, the information contents of the frequency can be greatly increased, the method does not depend on the finite element model of the structure, an anti-noise capability is high, operationis simple and is easy to implement, and a good application prospect is possessed.

Owner:DALIAN UNIV OF TECH

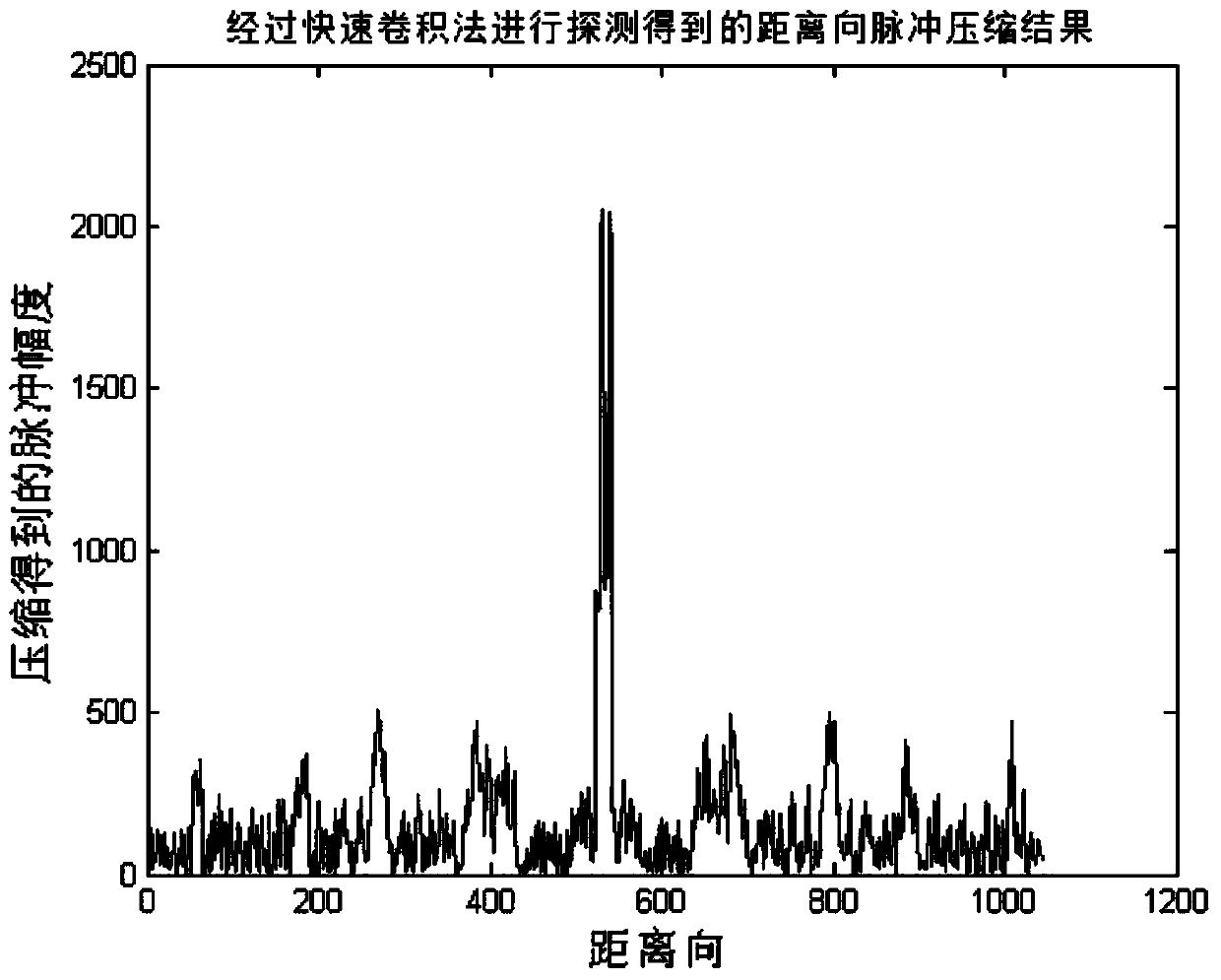

Method for applying M sequence to phase encoding system imaging radar pulse compression

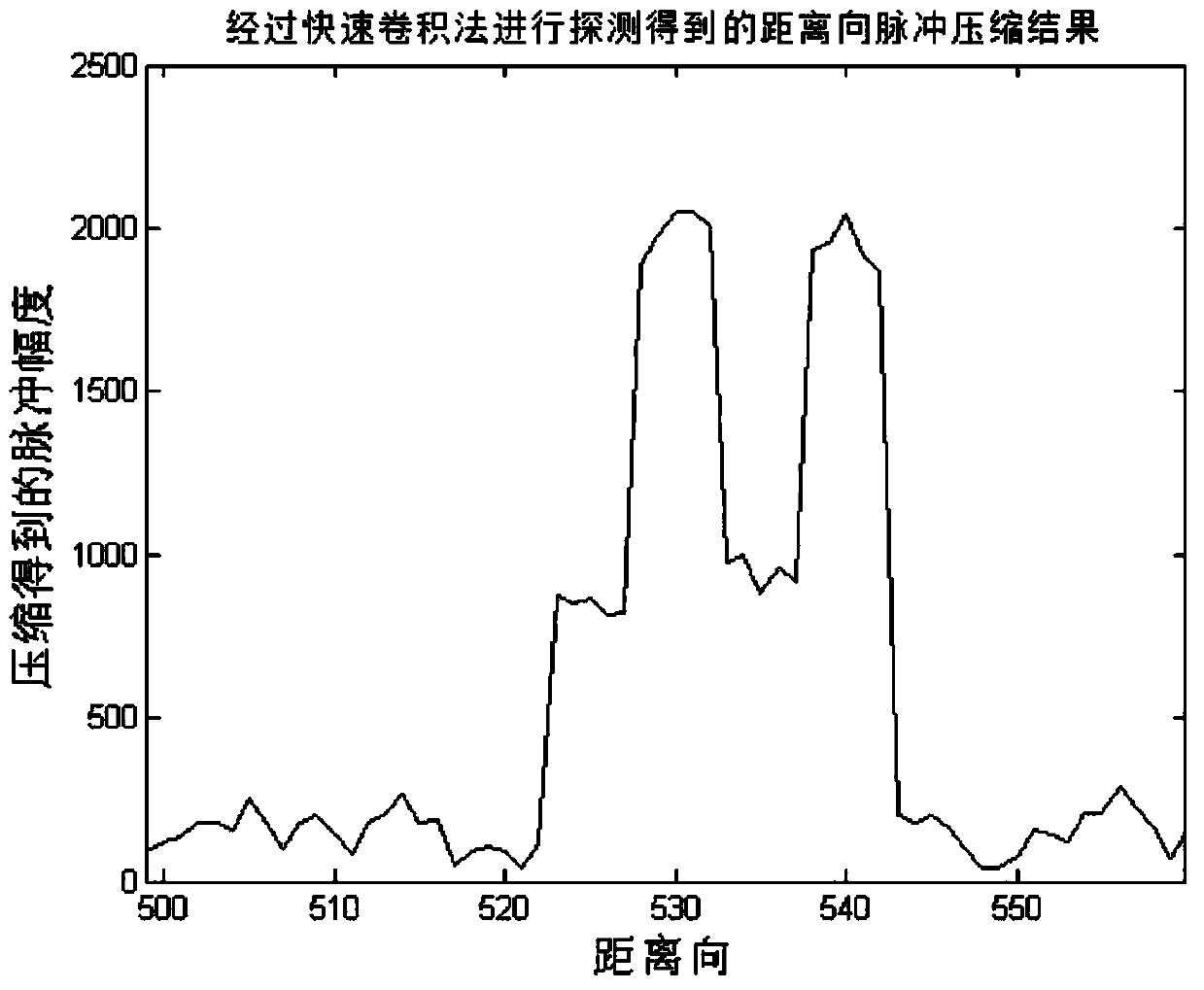

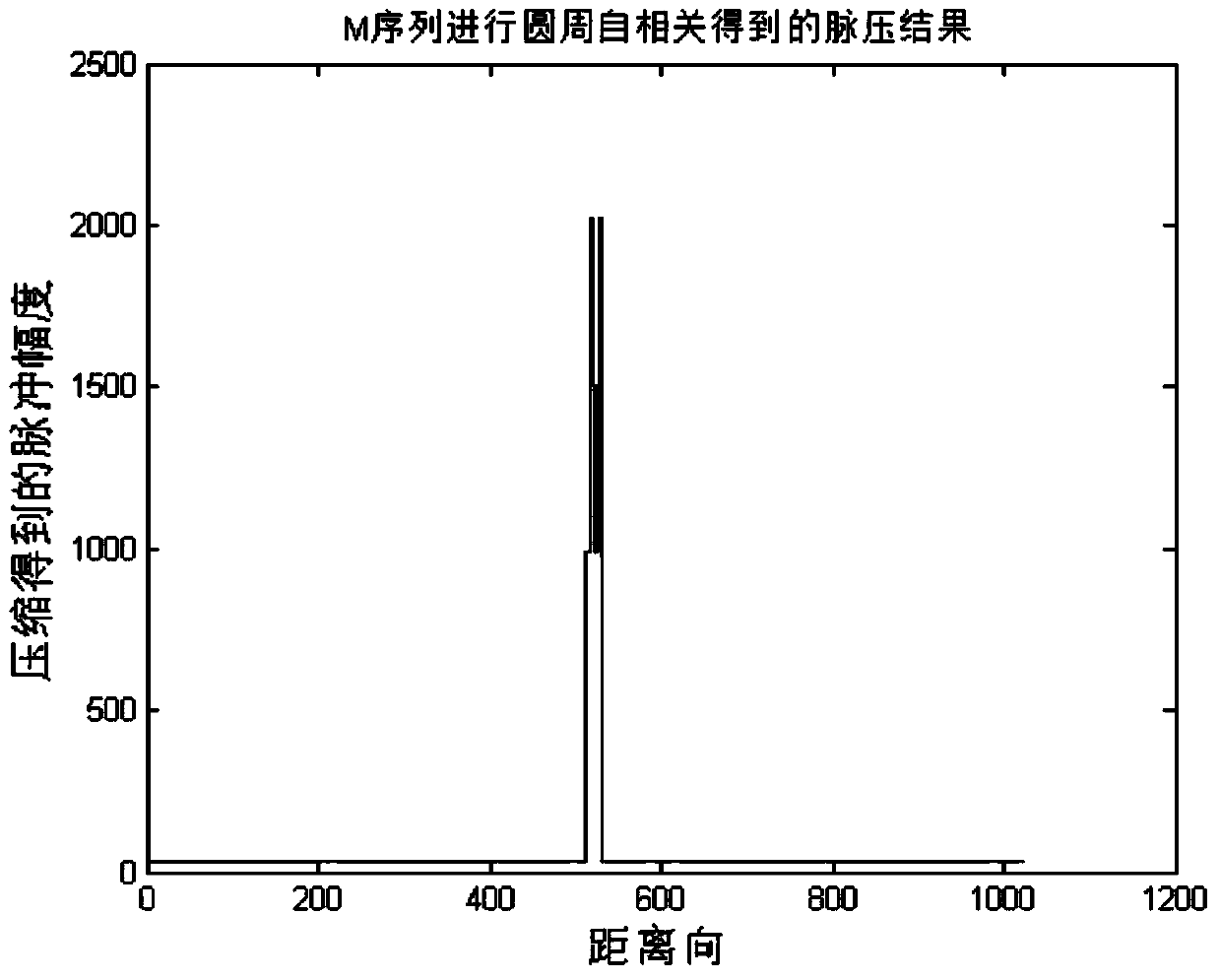

InactiveCN103792527AEasy to implementThe data processing method is simpleElectromagnetic wave reradiationSynthetic aperture radarImaging quality

The invention discloses a method for applying an M sequence to phase encoding system imaging radar pulse compression. The method is applied to a laser synthetic aperture radar imaging system. With the method adopted, the problem of imaging quality reduction and existence of virtual images which are caused by excessive sidelobe which is further caused by a situation that a traditional pulse compression system adopts a fast convolution method to perform pulse compression, can be solved. According to the method of the invention, phase codes are the M sequence, and the algorithm of pulse compression is a periodic convolution method. The method is characterized in that a matrix which is used for the pulse compression and is constructed in a manner that the M sequence is prolonged and is subjected to shifting operation so as to form the matrix is used so as to match the design of a filter. With the method adopted, sidelobe suppression can be realized under the premise that the complexity of the algorithm is not increased, and the sidelobe can be suppressed to be 1 / P under the condition that the length of code elements is P.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

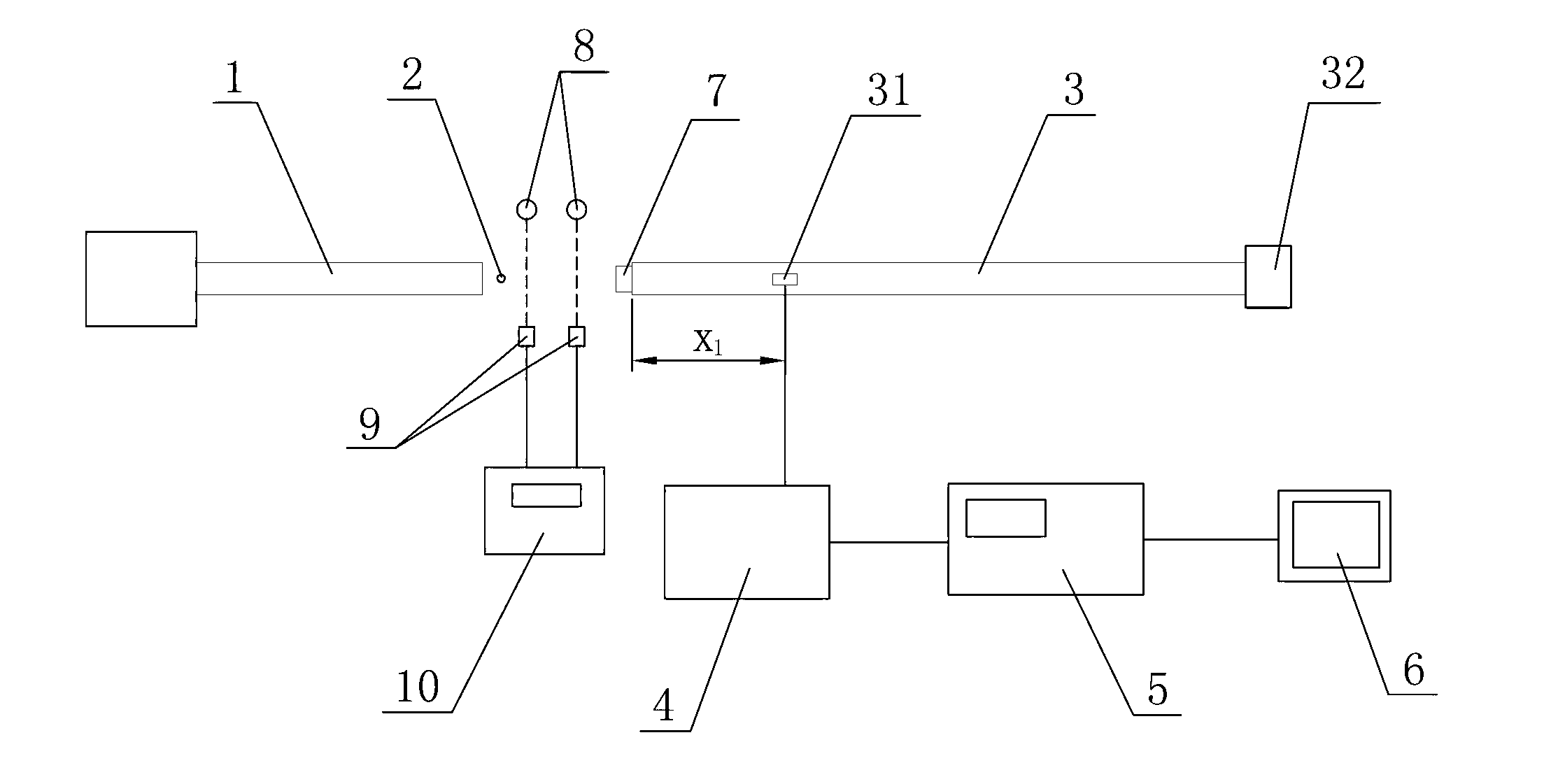

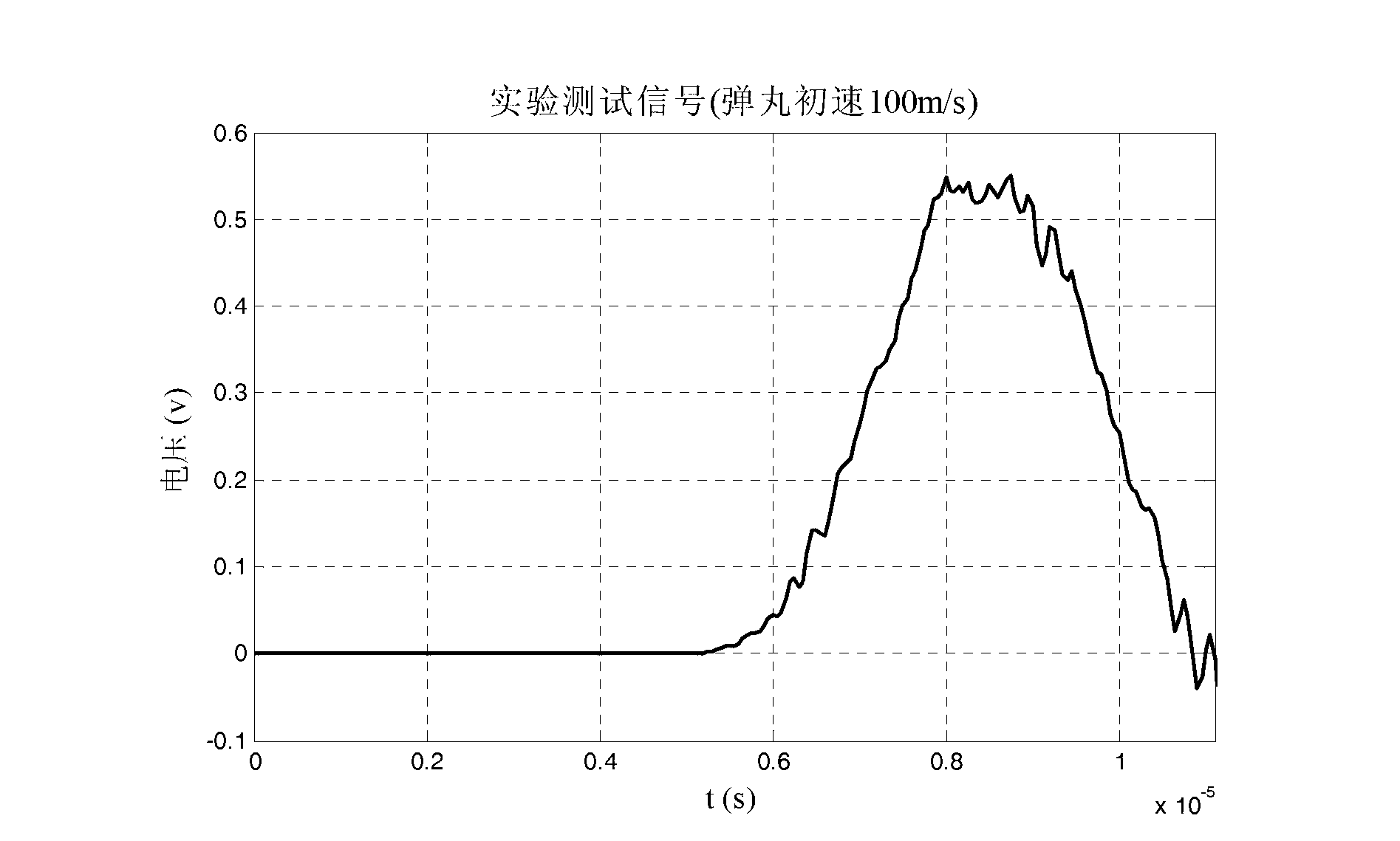

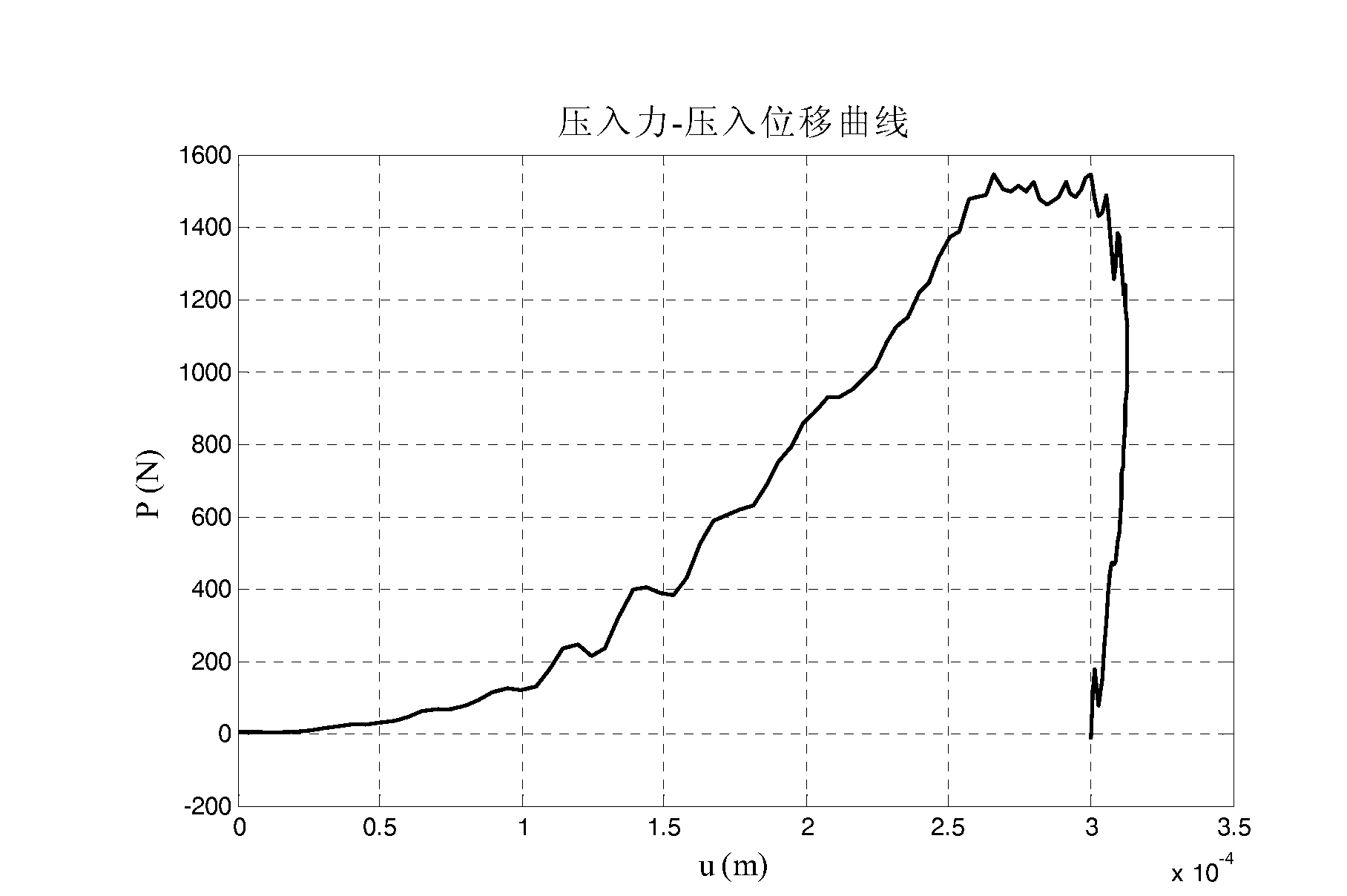

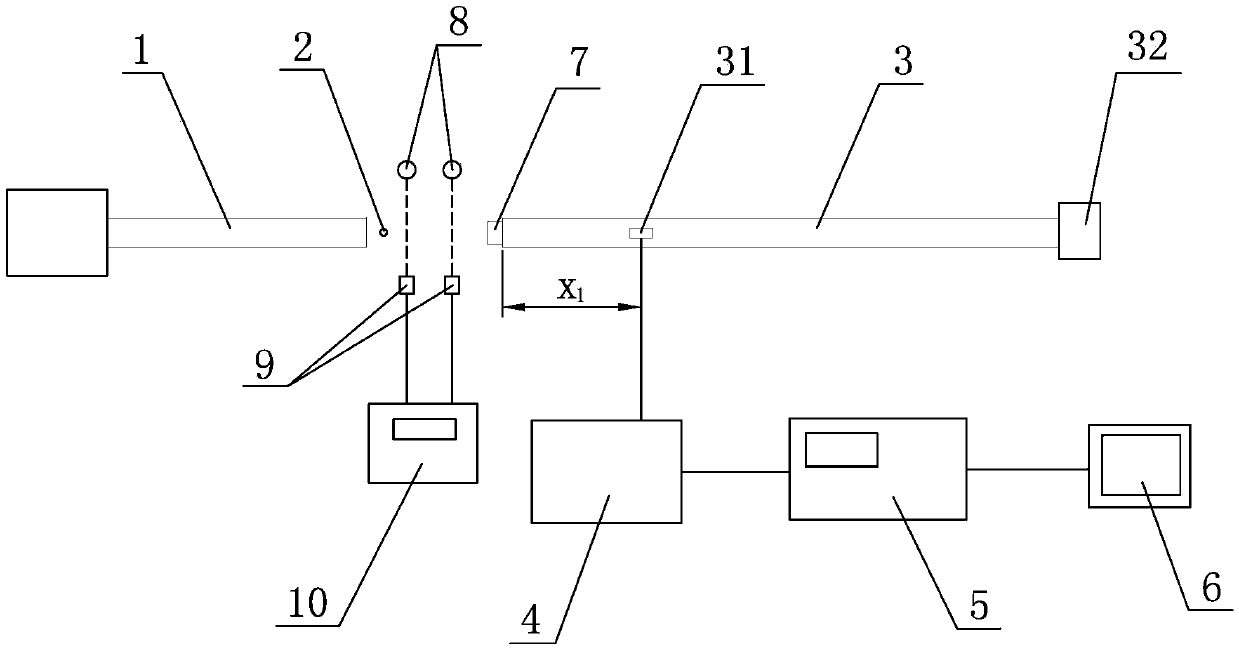

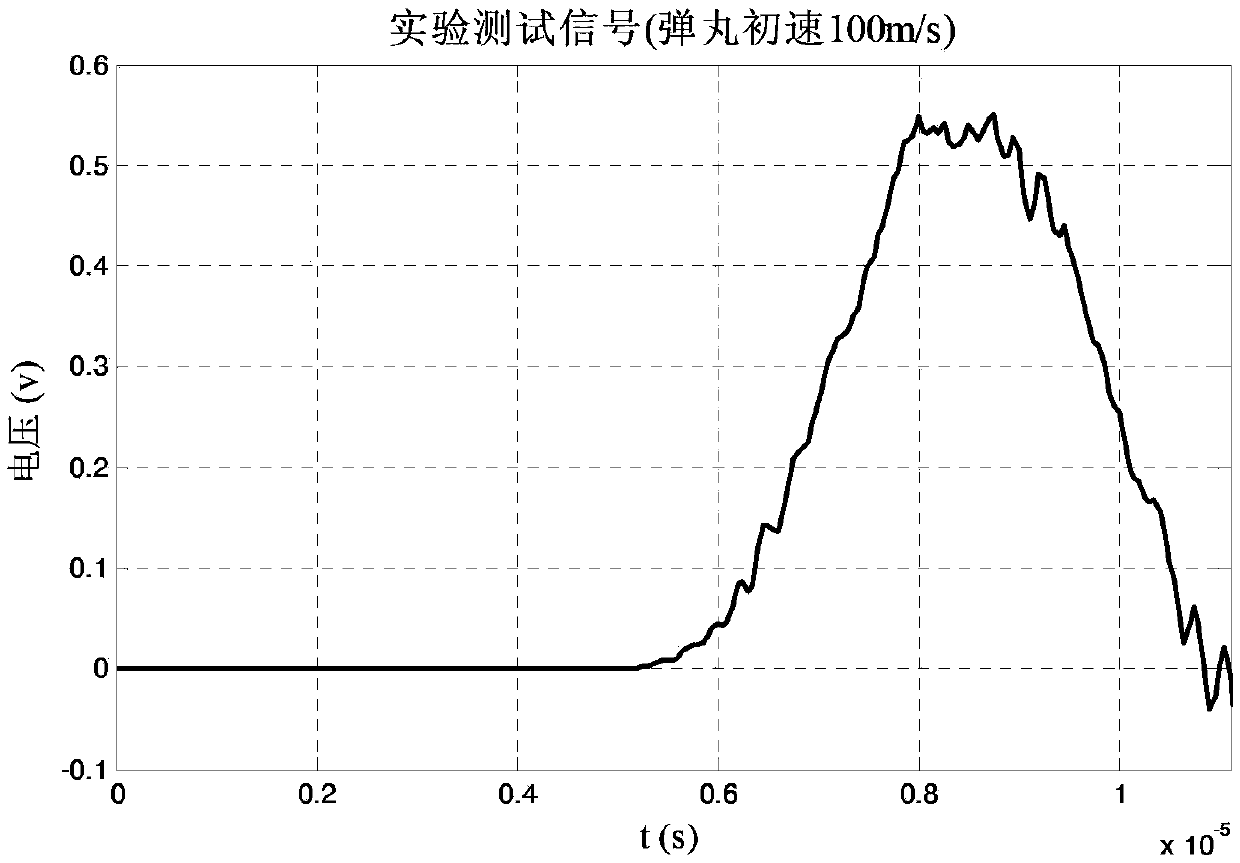

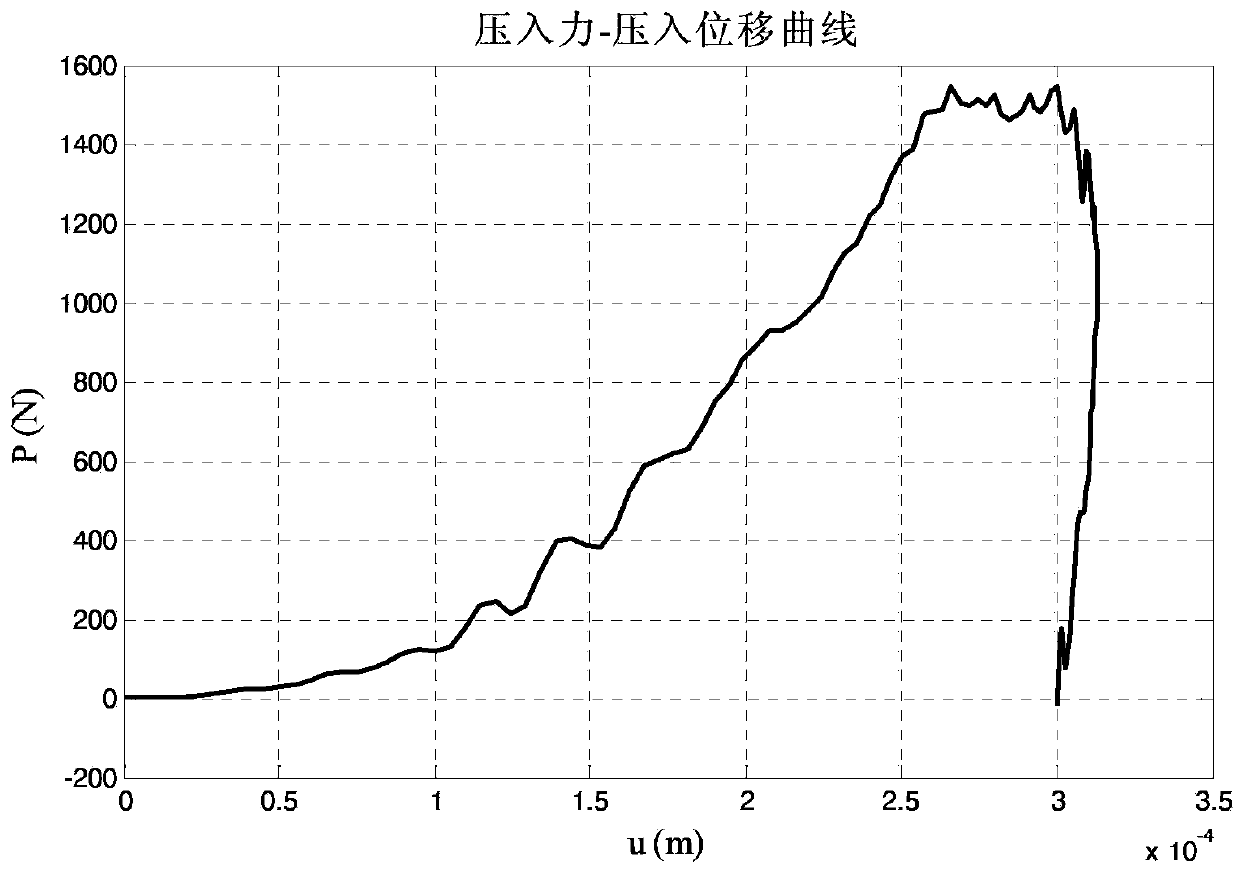

High-speed loading material dynamic indentation experimental method

InactiveCN103018123AHigh measurement accuracyStudy dynamic mechanical propertiesInvestigating material hardnessElectricityExperimental methods

The invention discloses a high-speed loading material dynamic indentation experimental method which is characterized by comprising the following steps of: firstly, fixedly arranging a cylindrical tested part on the end face of the front end of a circular section compression bar, adhering a strain gauge to the compression bar and electrically connecting the strain gauge and a high dynamic strain indicator; then fixedly arranging a light-triggered speed measurement device in front of the tested part; launching a shot by a shot lunching device and enabling the shot to pass through the light-triggered speed measurement device to impact the tested part; and finally, obtaining a press-in force, a press-in speed and a press-in displacement time history of the tested part by a relation. The high-speed loading material dynamic indentation experimental method has the advantages that by the experimental method, dynamic mechanical properties (such as the press-in force, the press-in speed and the press-in displacement time history) of the tested part in the impact process can be measured, so that the dynamic mechanical properties of a material are more deeply researched; moreover, the method can be suitable for a higher impact speed; the impact speed can reach 100m / s; and meanwhile, the experimental method has high measurement accuracy and adopts a simple data processing method.

Owner:NINGBO UNIV

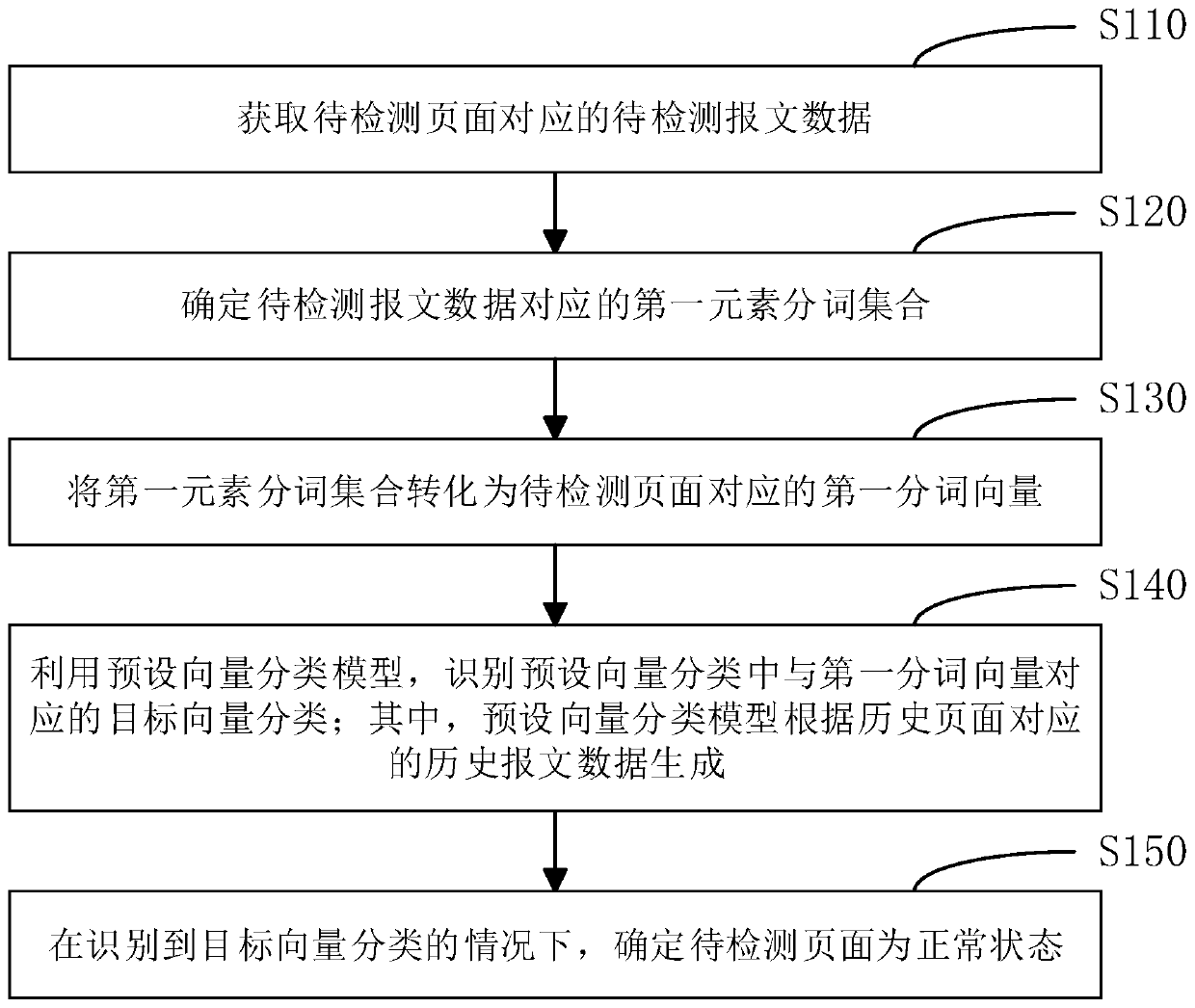

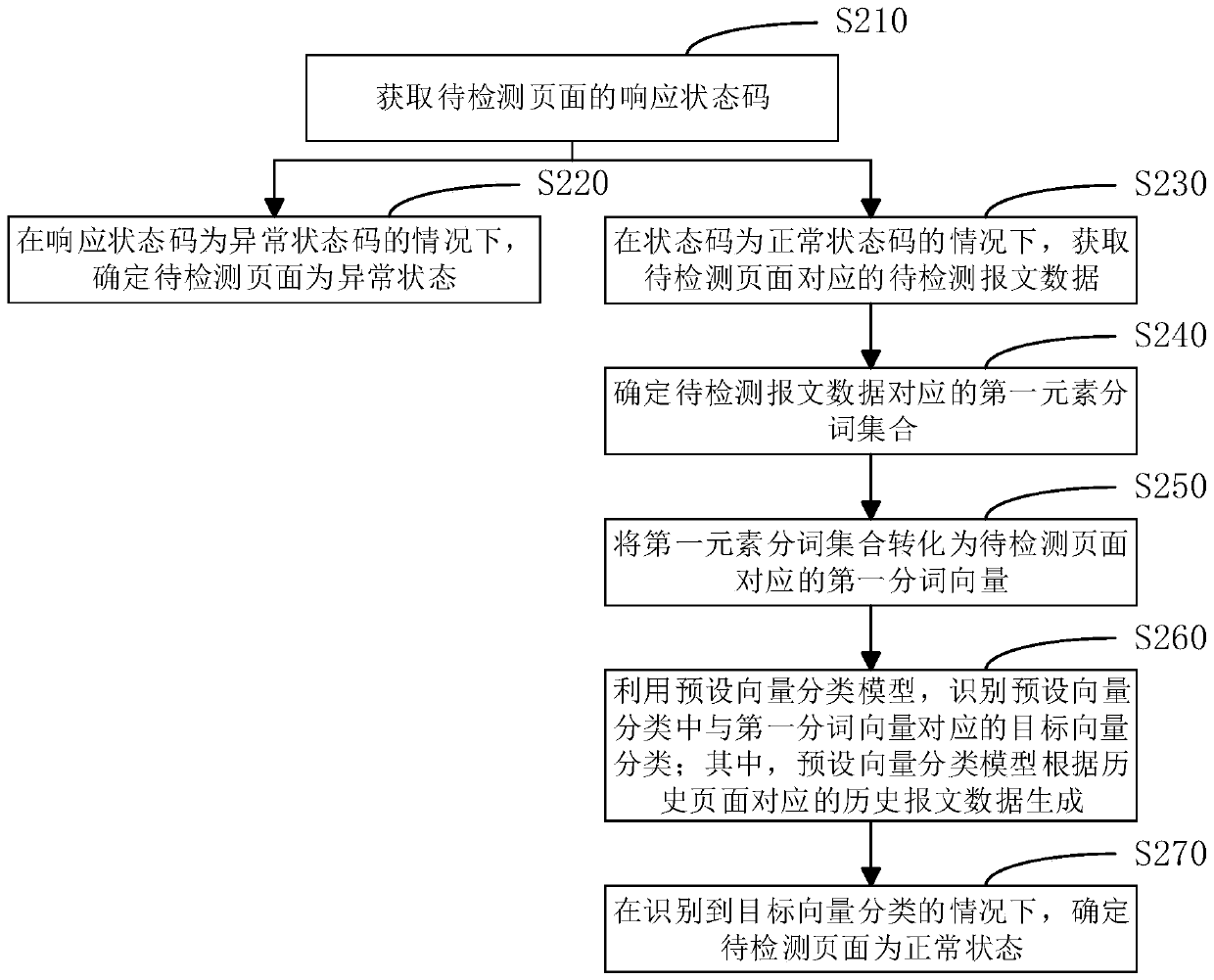

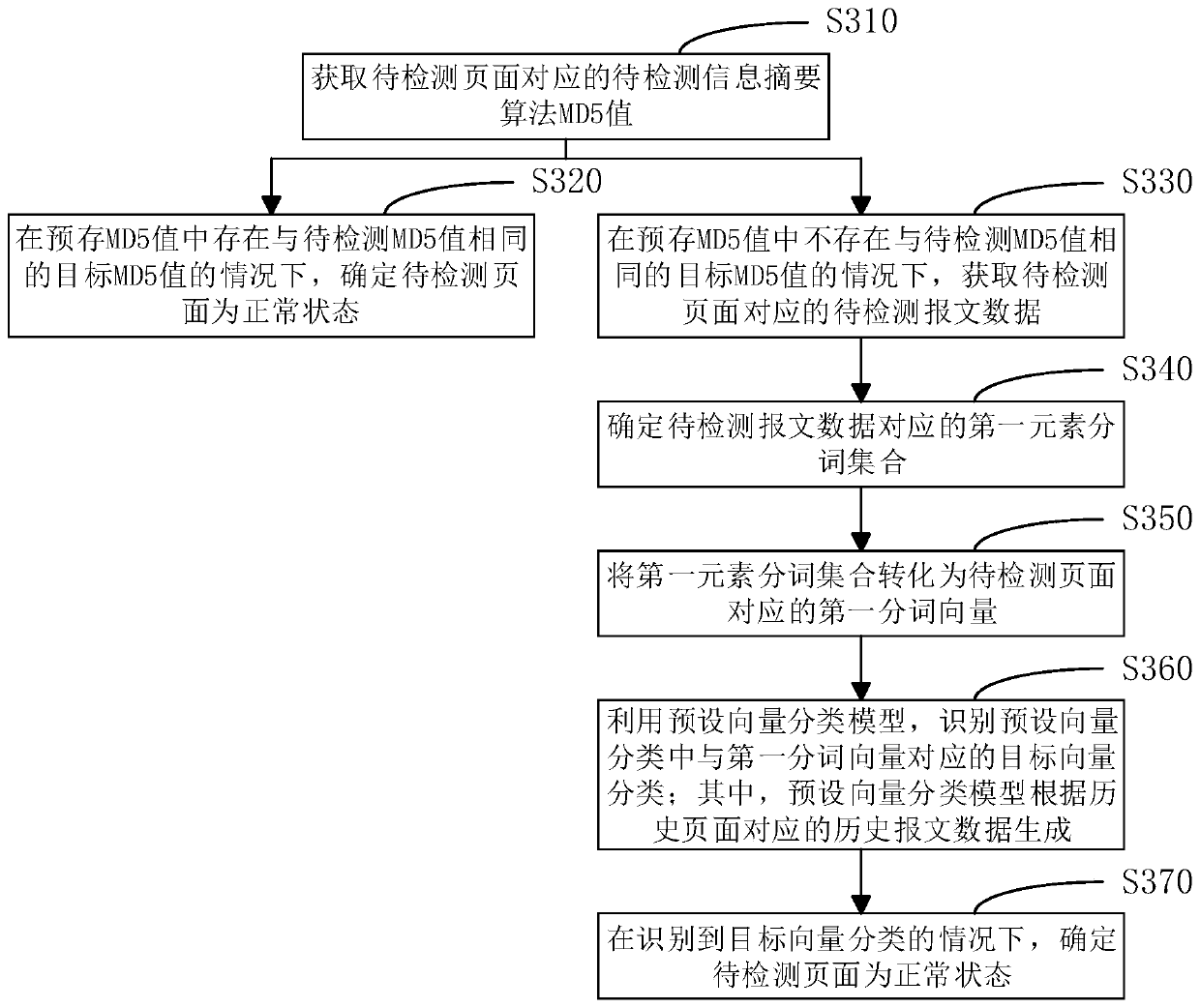

Page monitoring method, apparatus and device and computer readable storage medium

ActiveCN110674442ALower performance requirementsReduce data processingWebsite content managementEnergy efficient computingEngineeringData mining

The invention discloses a page monitoring method, apparatus and device, and a computer readable storage medium. The page monitoring method comprises the steps of obtaining to-be-detected message datacorresponding to a to-be-detected page; determining a first element word segmentation set corresponding to the to-be-detected message data; converting the first element word segmentation set into a first word segmentation vector corresponding to the to-be-detected page; utilizing a preset vector classification model to identify a target vector classification corresponding to the first word segmentation vector in the preset vector classification, wherein the preset vector classification model is generated according to historical message data corresponding to a historical page; and under the condition that the target vector classification is identified, determining that the to-be-detected page is in a normal state. According to the embodiment of the invention, whether the to-be-detected pageof the webpage is in the normal state or not can be accurately and efficiently judged.

Owner:CHINA UNIONPAY

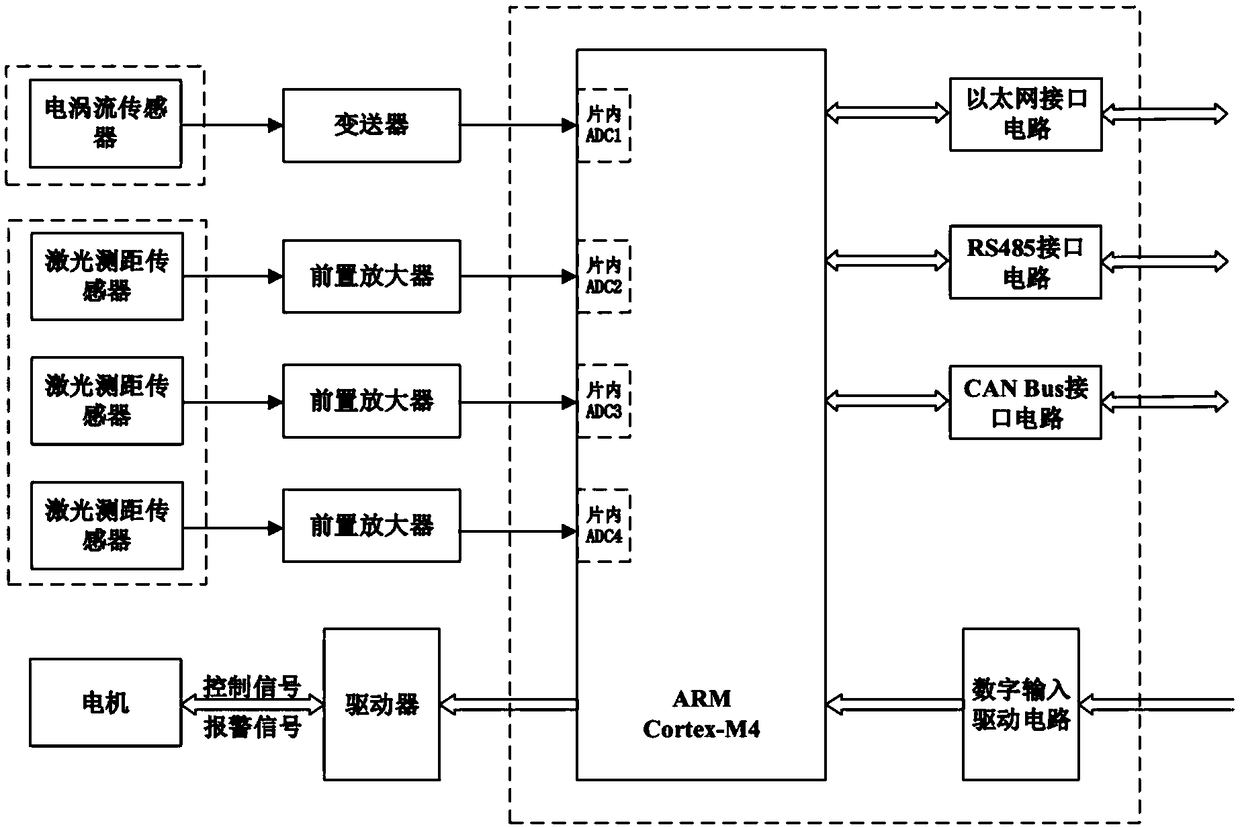

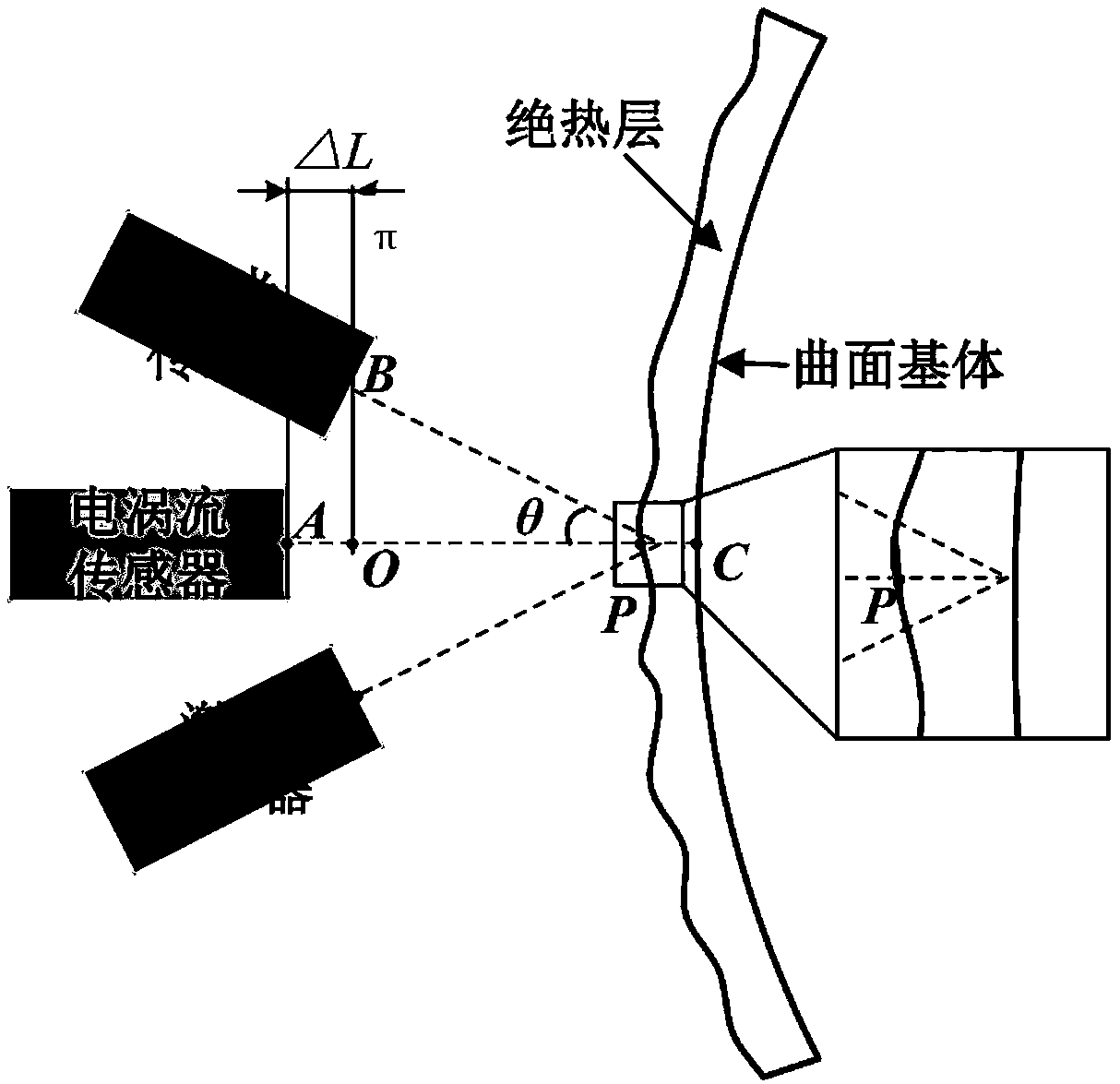

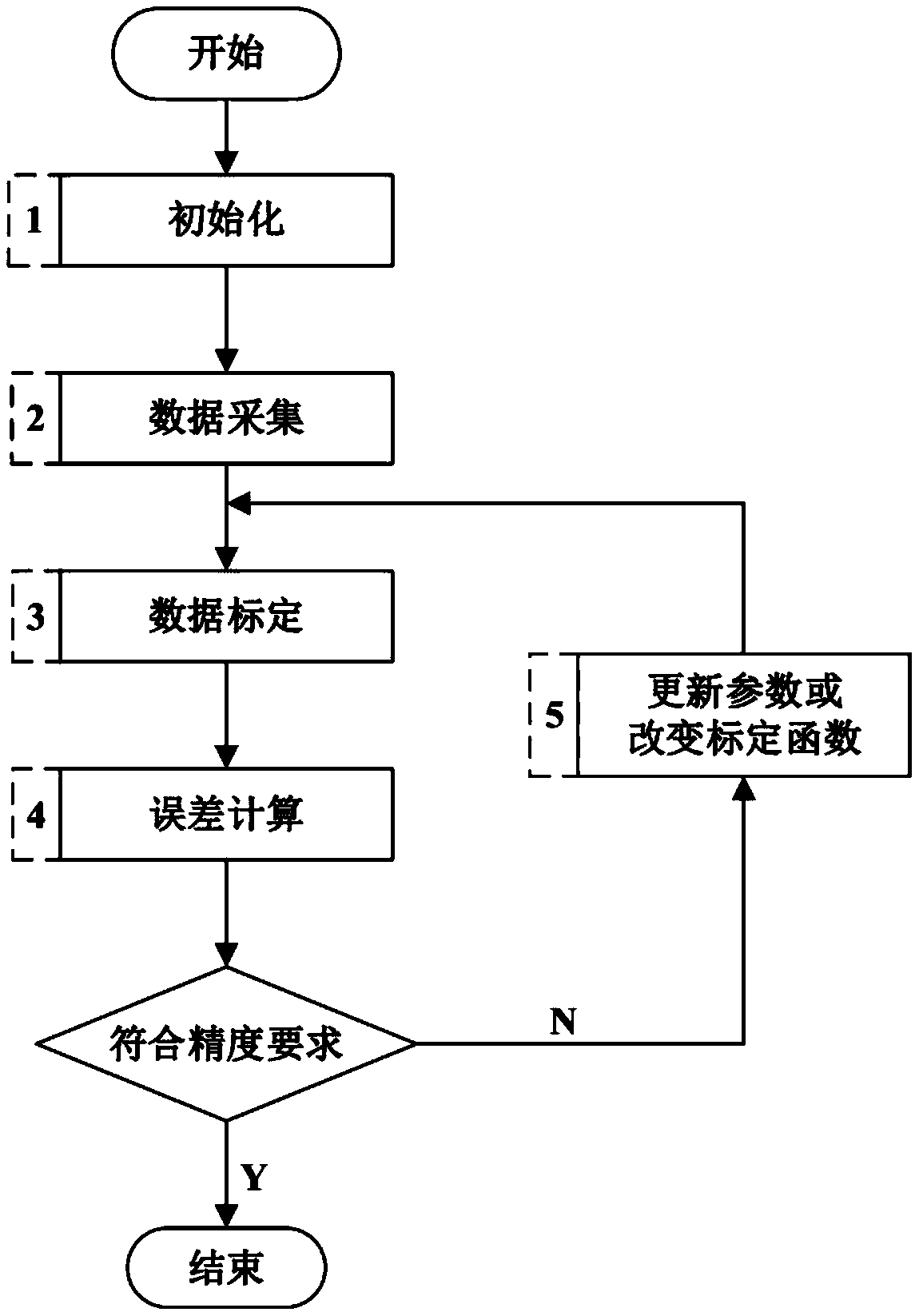

Non-contact type measuring method and device for metal surface coating thickness

ActiveCN109141325ASolve the errorSolve the accuracy problemUsing electrical meansUsing optical meansElectricityLaser ranging

Provided is a non-contact type measuring method and device for metal surface coating thickness, and a non-contact type eddy current detection probe is correspondingly selected according to the size ofa to-be-tested piece so as to carry out calibration, so that a relation curve of the eddy current signal and the corresponding lifting distance is obtained, and a metal matrix vortex ranging model ofthe to-be-tested piece is built, a vortex signal of the eddy current sensor is obtained in the detection process, and the distance from the center point of the metal matrix vortex area to the end surface of the eddy current probe according to the metal matrix vortex ranging model of the to-be-tested piece, and further the distance from the center point of the outer surface of the coating layer ofthe eddy current area to the plane, namely, the detection plane Pi where the light projection point of the laser ranging sensor group is located is measured according to the laser ranging sensor group, and finally the metal matrix surface coating thickness is obtained through calculation. According to the invention, stable and reliable nondestructive non-contact detection can be realized, and thedata processing method is simple, on-line detection is easy, so that a lot of economic cost and time are saved.

Owner:SHANGHAI JIAO TONG UNIV +1

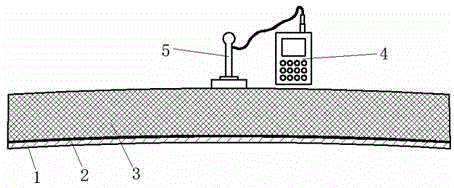

Method for measuring thickness of foam plastic board with eddy current method

InactiveCN104567647AAvoid water resistanceRealize non-destructive thickness measurementElectrical/magnetic thickness measurementsEddy currentEngineering

The invention provides a method for measuring thickness of foam plastic. The method comprises steps as follows: (1), a probe of an eddy current thickness measurement instrument is put on a surface of the foam plastic; (2), pressure is exerted according to a use requirement of the probe; (3), the thickness of the measured foam plastic is obtained according to a number displayed on a reading dial of a host of the eddy current thickness measurement instrument. The method solves the problem that the foam plastic is damaged during thickness measurement with a conventional foam plastic thickness measurement method.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

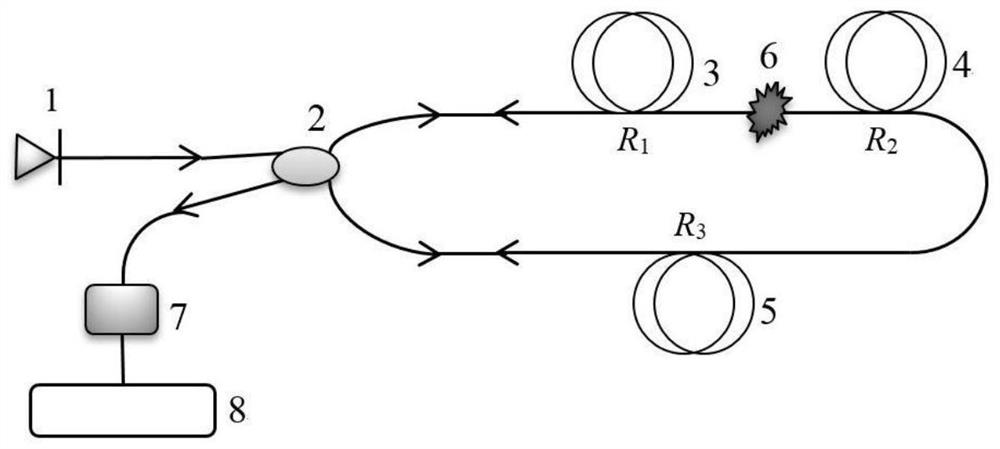

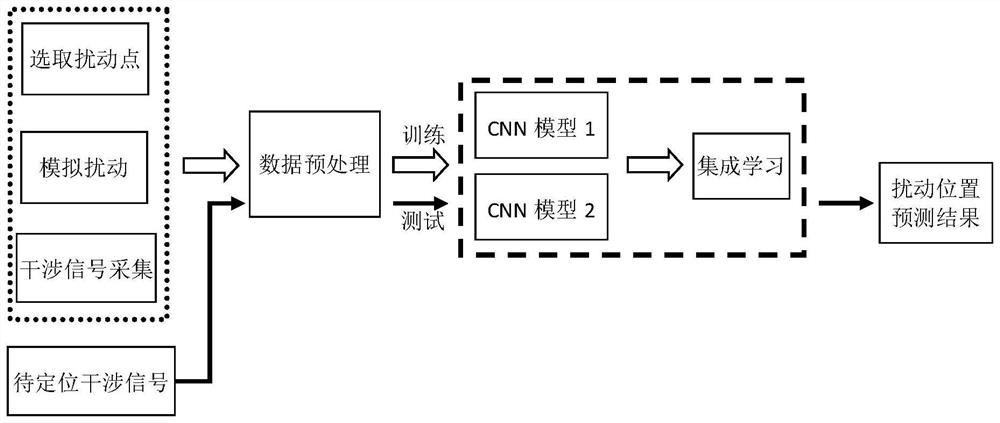

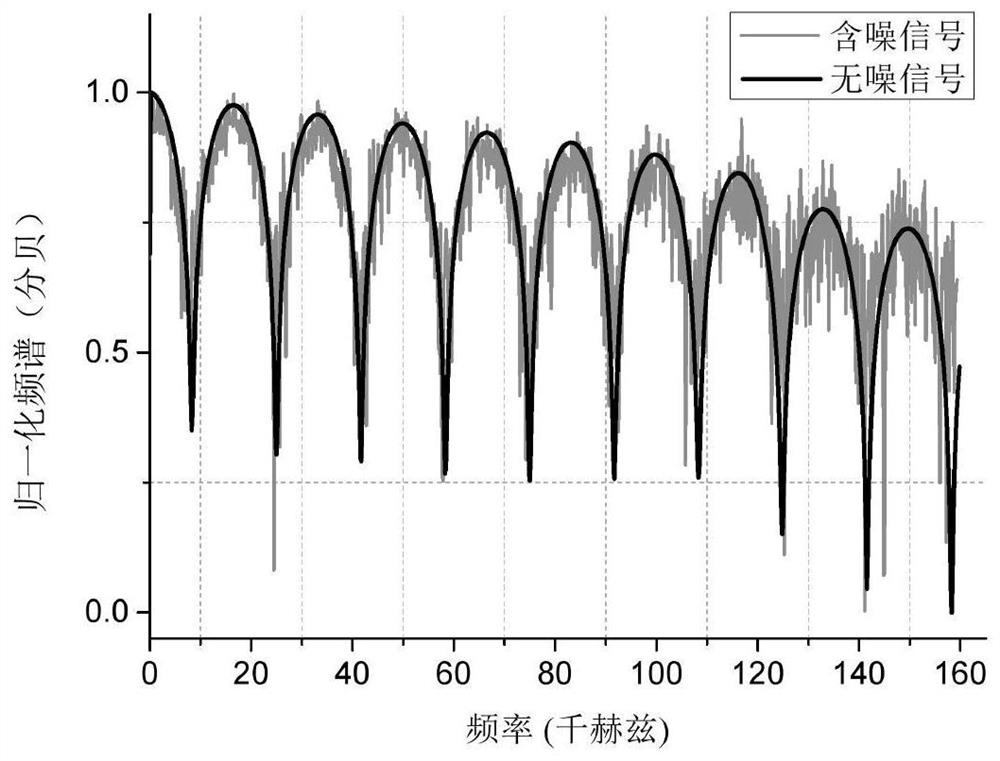

Positioning method for Sagnac distributed optical fiber sensing system based on convolutional neural network ensemble learning

ActiveCN112539772AGood training effectReduce complexityEnsemble learningNeural architecturesAlgorithmTest sample

The invention discloses a positioning method for a Sagnac distributed optical fiber sensing system based on convolutional neural network ensemble learning. The method comprises the steps of taking a fixed interval point on a sensing optical fiber as a disturbance point, enabling the sensing system to obtain an interference signal generated by the simulation disturbance of each point, carrying outthe preprocessing of the interference signal, and enabling the preprocessed interference signal to serve as a training set and a verification set, training two convolutional neural network models fordifferent loss functions to enable the two CNN models to accurately position near-end and far-end disturbances respectively, combining training results of the two models through an ensemble learning method to obtain a disturbance position prediction model based on CNN ensemble learning, and optimizing parameters of each model through the verification set. A to-be-positioned interference signal ispre-processed as a test sample, and the to-be-positioned interference signal is tested by using the trained prediction model to obtain a disturbance position of the to-be-positioned interference signal. The method does not need signal demodulation, is low in system complexity, is not sensitive to noise, is simple in data processing method, is stable and accurate in positioning result, and can be used for the disturbance positioning of an annular or linear Sagnac distribution optical fiber sensing system.

Owner:SHANGHAI UNIV

Minimum distance sorting method assisted by digital mapping brief spelling coding method and internal sorting method

InactiveCN102467573ASave field timeReduce workloadMaps/plans/chartsSpecial data processing applicationsShortest distanceJoin point

The invention discloses a minimum distance sorting method assisted by a digital mapping brief spelling coding method and an internal sorting method, which is directly applied in the technical field of the total field digital mapping. The brief spelling coding method is composed of a type code+ (a series number)+ (a descriptor)+ (a feature code)+ (-an attribute code)(contents in the brackets are selectable), wherein the measured data is sorted by the minimum distance sorting method assisted by the brief spelling coding method. The minimum distance sorting method is as follows: sequentially calculating distances between the base point and the rest points from the starting point of the surface feature data point and taking the starting point of the surface feature data point as the base point, and selecting the data point with the shortest distance as the connection point with the base point, and taking the selected point with the shortest distance as the base point again, and sequentially calculating the distances between the base point and the rest points, and selecting the data point with the shortest distance as the connection point with the base point, and repeating the steps until no rest points are left; finally, sorting the data points with the shortest distances from each selection based on the precedence such that the sequence fully ensures the connection relationship between each surface feature data point and the other points. The minimum distance sorting method can achieve full automation on field mapping fast coding and interior data processing and map making.

Owner:王尚奇 +1

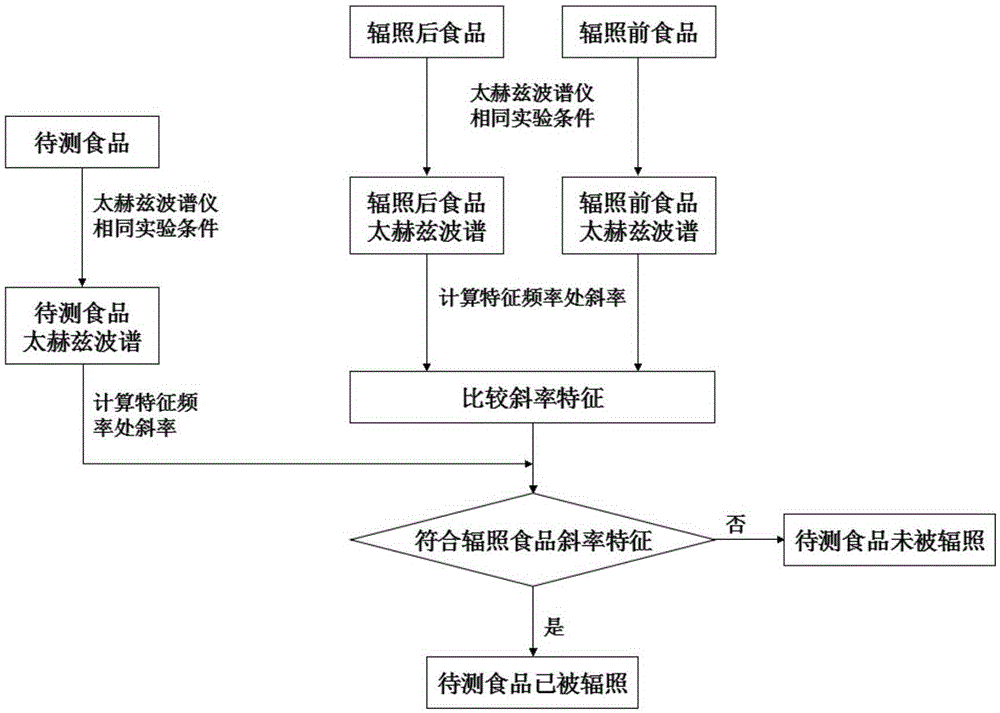

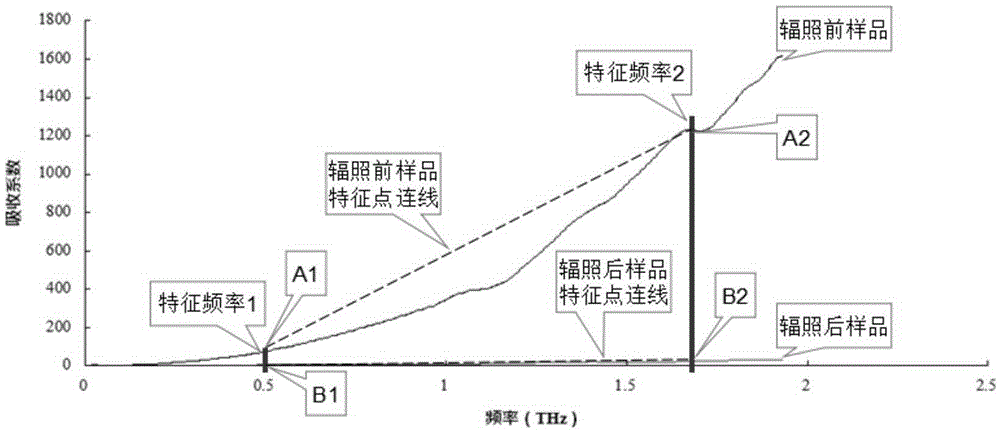

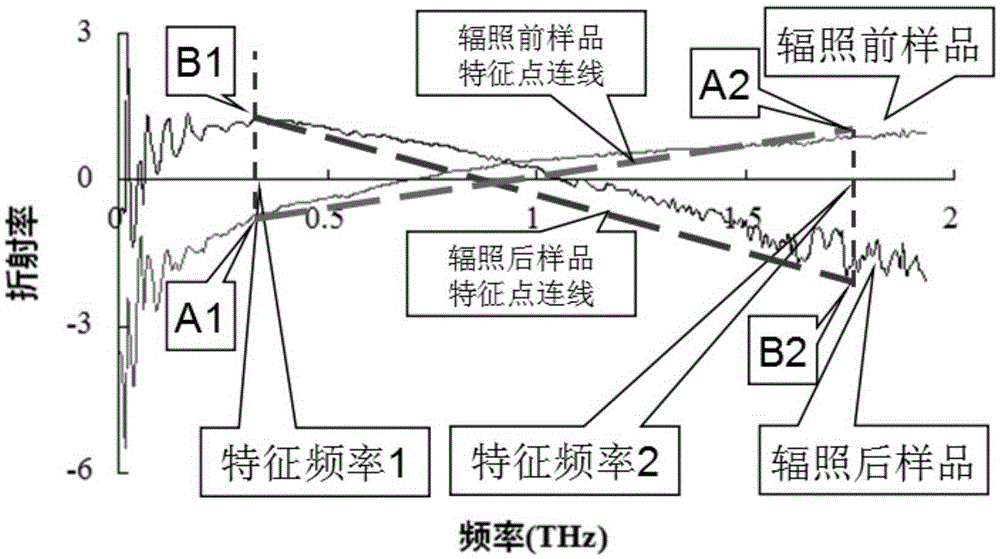

Rapid detection method for irradiated food

ActiveCN105334181ARapid identificationProduce secondary pollutionMaterial analysis by optical meansFood safetyRadioactive source

The invention provides a rapid detection method for irradiated food. The rapid detection method for irradiated food is based on a terahertz spectrum technology, and comprises acquiring the terahertz spectrum of food with known irradiation status, analyzing the slope characteristic of a feature-point connecting line under the characteristic frequency of the food, then acquiring the terahertz spectrum of to-be-detected food under the same experiment conditions, and determining whether the to-be-detected food is irradiated by ionizing radiation generated by a radioactive source according to the slope characteristic of the feature-point connecting line of the to-be-detected food under the characteristic frequency. The method is capable of realizing rapid efficient environment-friendly identification on irradiated food, thereby providing important technological meaning for food safety monitoring, radioactive source safe usage and other aspects.

Owner:尼尔软科(北京)科技有限公司

Truss structure damage positioning method based on added mass

InactiveCN102495134BReduce testing costsEasy to operateAnalysing solids using sonic/ultrasonic/infrasonic wavesStructure of the EarthPeak value

The invention discloses a truss structure damage positioning method based on an added mass, and belongs to the technical field of structure monitoring. The truss structure damage positioning method is characterized in that: the damages to rod pieces of a truss are located by using a method for arranging and testing the rod pieces one by one through a mass block and a sensor. The bending stiffnessof the rod pieces of the truss is required to be smaller than the axial rigidity; a response under partial excitation mainly reflects rod piece information; and the damage positions of the rod piecesare judged by comparing the positions of mass-added rod piece frequency response peak values. According to the method, the shortcomings that the truss structure is insensitive to partial damages and the damage positioning of the rod pieces is difficult to perform are overcome; and the method has the characteristics of simple actual operation, low cost, accurate identification and the like, and isgood in application prospect.

Owner:DALIAN UNIV OF TECH

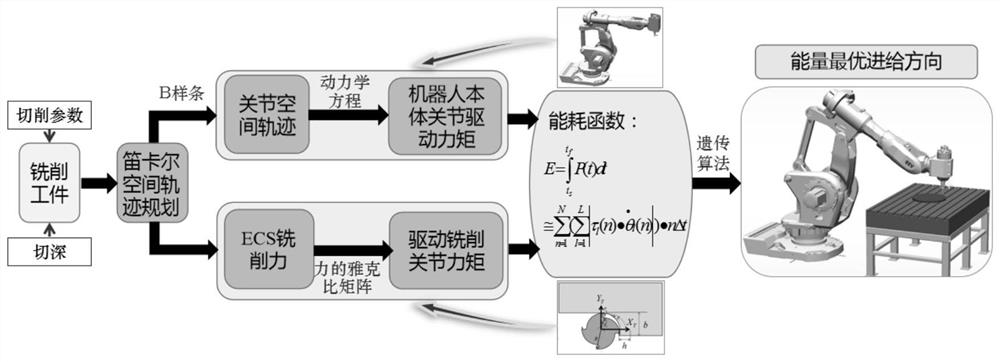

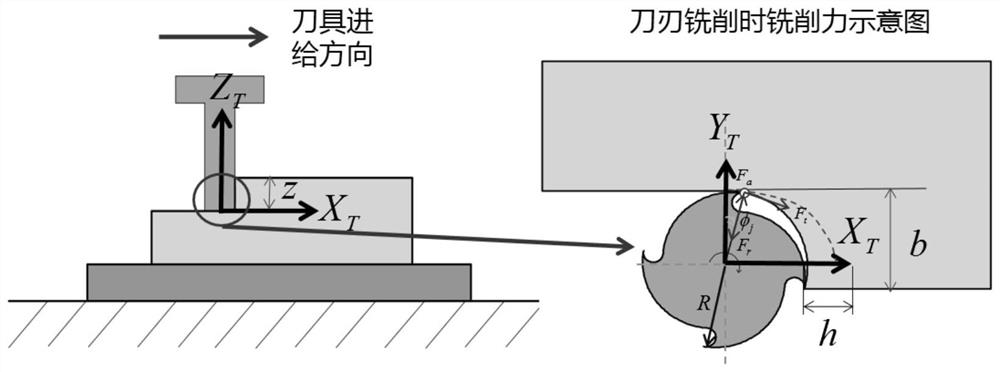

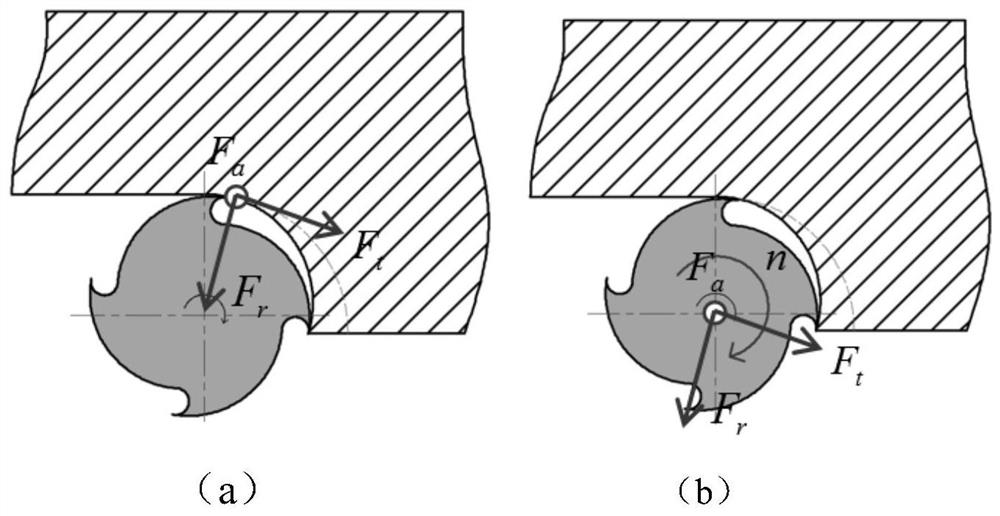

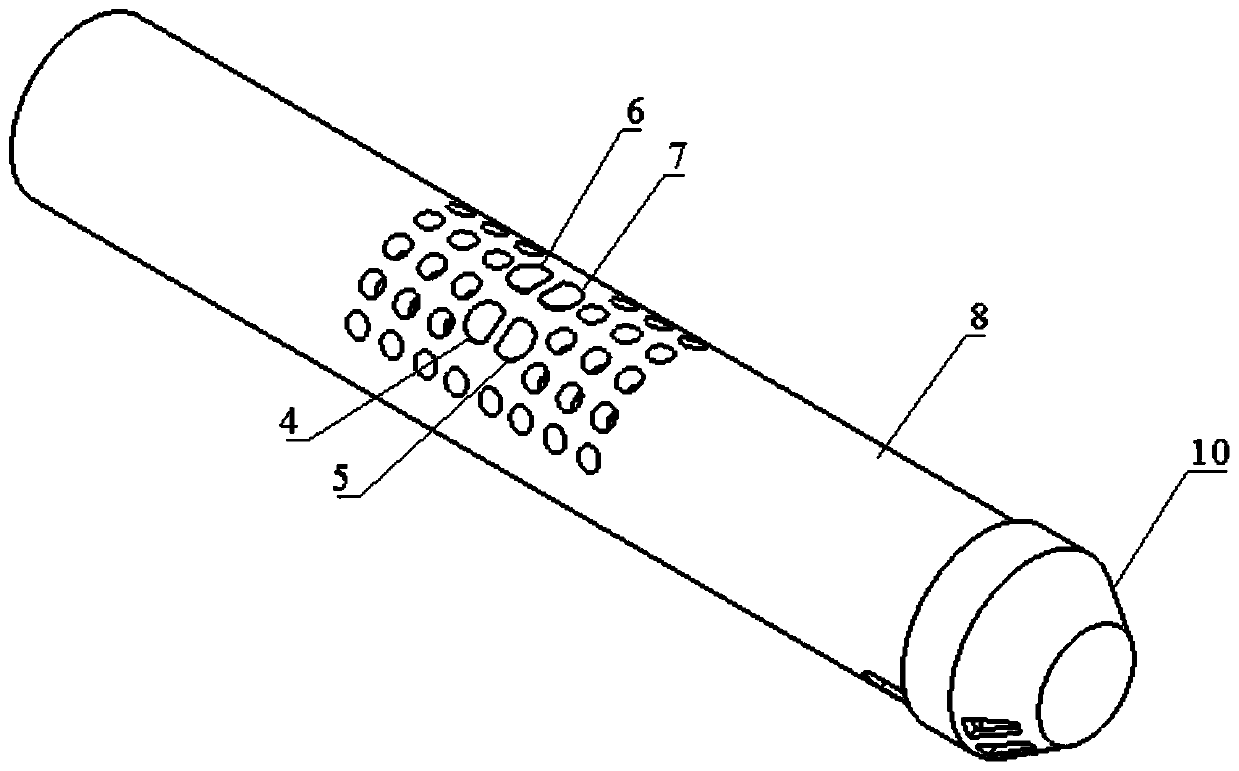

Robot milling feeding direction optimization method based on energy optimization

ActiveCN113145907AAccurate descriptionAccurate calculationProgramme-controlled manipulatorMilling equipment detailsDynamic modelsProcess engineering

The invention belongs to the related technical field of milling, and discloses a robot milling feeding direction optimization method based on energy optimization. The method comprises the following steps: S1, for a to-be-milled workpiece, a processing track of the to-be-milled workpiece in a Cartesian space is planned; S2, the machining process of the workpiece to be milled is divided into a tool falling stage, a milling stage and a tool lifting stage, a dynamic model of a milling robot and a milling force model under a robot coordinate system are constructed, and robot joint torque and joint speed corresponding to each stage are solved and obtained accordingly; and S3, an energy consumption relational expression of each stage is constructed, a total energy consumption optimization model of the whole machining process is constructed according to the energy consumption relational expression, the corresponding feeding direction under the condition of the minimum energy consumption is solved, the optimal feeding direction is obtained accordingly, and then optimization of the feeding direction under the condition of the optimal energy is achieved. According to the method, the energy consumption is reduced, the processing cost is reduced, the joint impact can be reduced, the milling quality is improved, and the service life of the robot is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

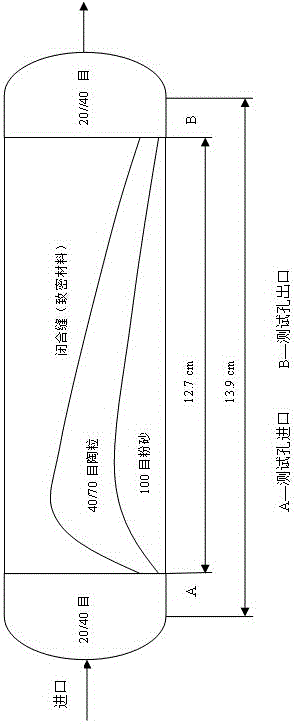

Temperature regulating device used for handle and regulating method thereof

The invention discloses a temperature regulating device used for a handle and a regulating method thereof. The temperature regulating device comprises a temperature sensor array and a controller, wherein the temperature sensor array is arranged on a hollow handle; the interior of the hollow handle is provided with a heating plate and a refrigerant plate; a protective cover is arranged at one end of the hollow handle; the protective cover is internally provided with a fan; and the heating plate, the refrigerant plate, the temperature sensor array and the fan are connected with the controller through a control circuit respectively. The temperature regulating device solves the defects that the temperature of a palm is seriously influenced by the environment when the handle is grasped by a user in the prior art and cannot be maintained in a comfortable range and the hand comfort of the user is influenced.

Owner:XI AN JIAOTONG UNIV

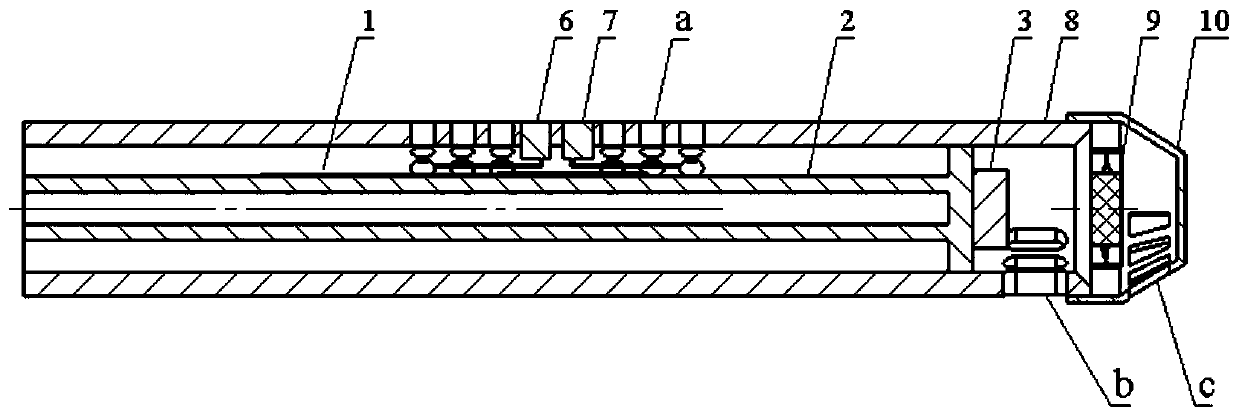

Evaluation method for fracture conductivity of shale gas combined with sand and fracturing

ActiveCN104358554BImprove diversion capacityThe test method is practicalFluid removalGeomorphologyLinear regression

The invention discloses a method applied to evaluation of flow conductivity of shale-gas-combined sand fracturing fracture. The method comprises the following steps: a, simulating a sand bar transporting process in shale-gas-slickwater-combined sand fracturing fracture by means of an experiment device for simulating flowing of proppants in a visual fracture net to obtain sand bar transporting video of the combined sand fracturing fracture under different experiment conditions; b, obtaining a distribution curve of the proppants with different particle diameters by virtue of a gray processing method and a point-by-point scanning method and obtaining distribution shape function of the proppants with different particle diameters by virtue of a linear regression method; c, building the sand bar distribution shape function of an API flow guide chamber by utilizing geometric similarity principle according to the size of the API flow guide chamber, paving shapes of the corresponding proppants and implementing evaluation of flow conductivity of shale-gas-combined sand fracturing fracture. The method is capable of simply and accurately implementing quantitative evaluation of the flow conductivity of shale-gas-combined sand fracturing fracture; experiment support is provided for optimizing the combined sand fracturing design and improving the flow conductivity of the shale fracturing fracture.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

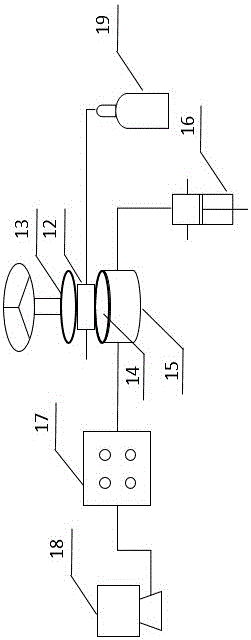

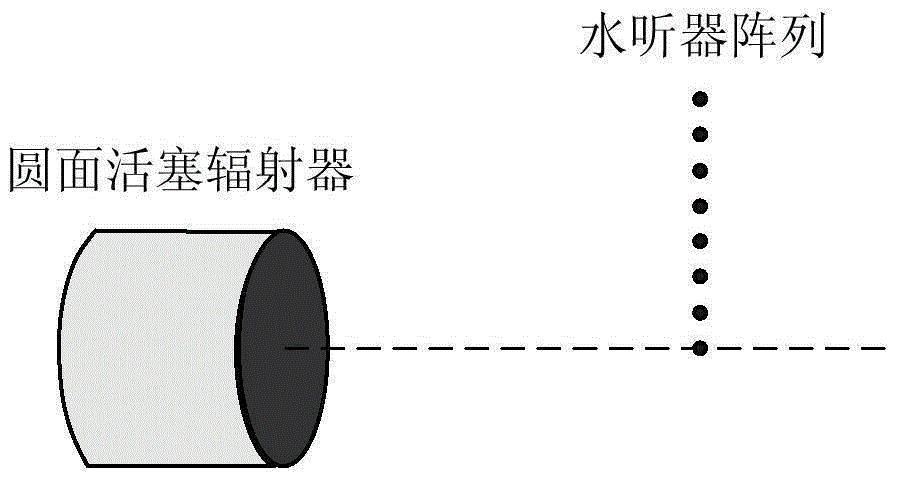

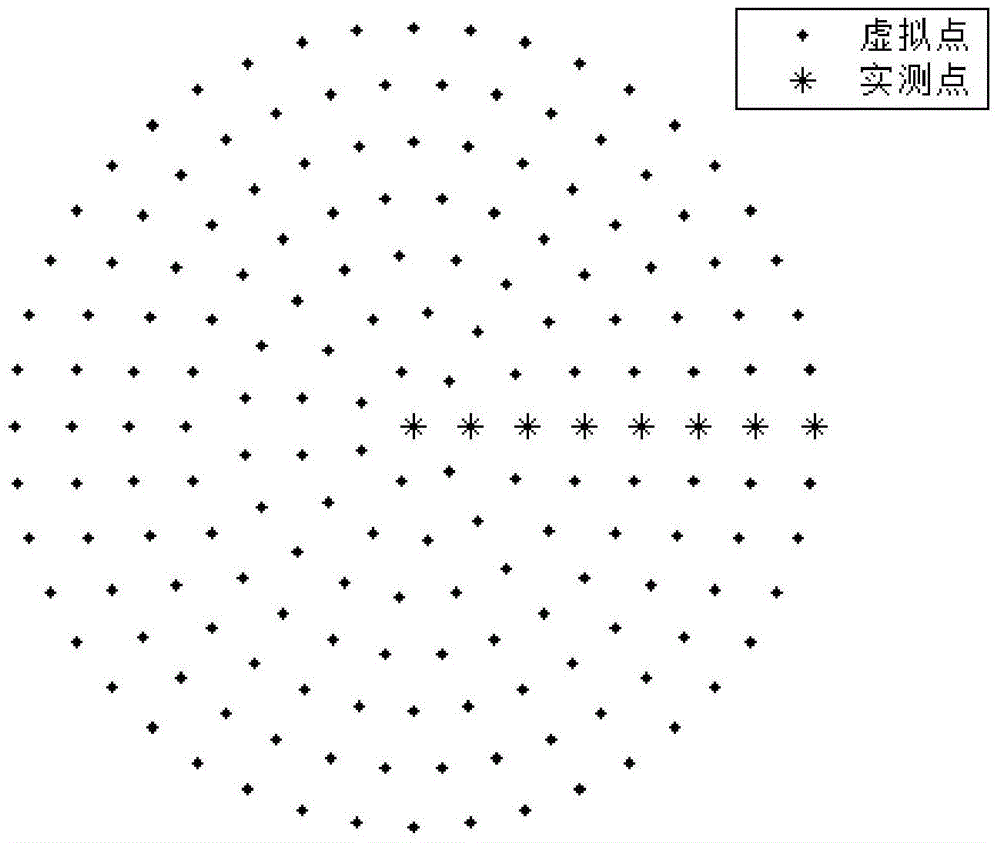

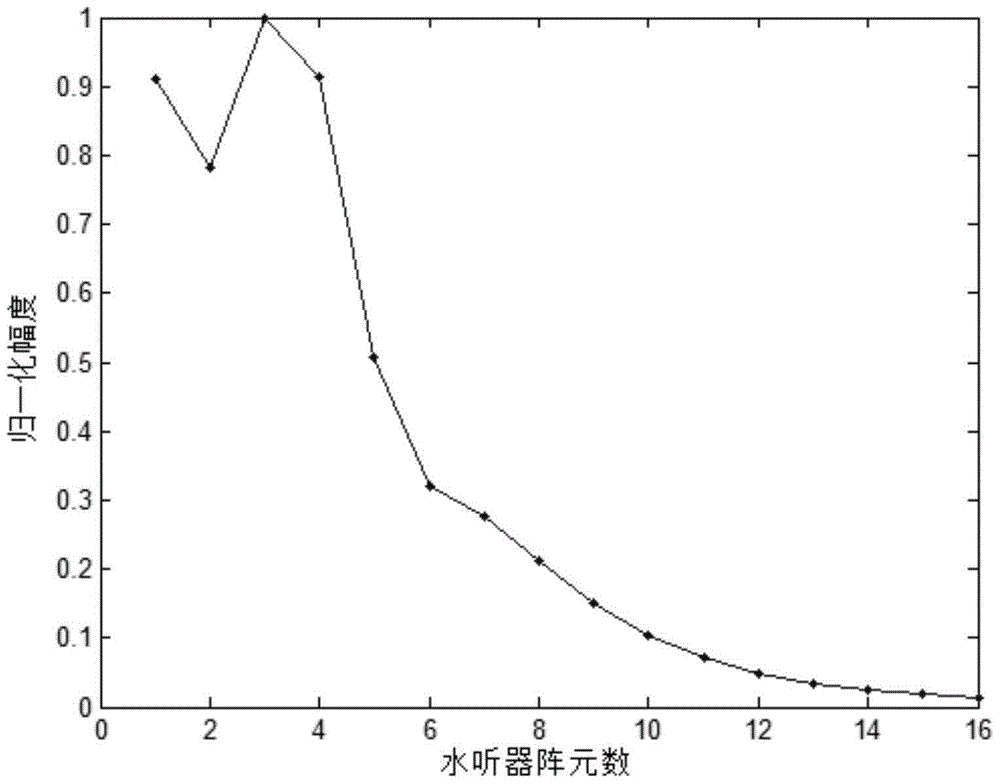

Directive near-field measurement data processing method for round-face piston radiator

ActiveCN105181123AThe data processing method is simpleEasy to implementVibration measurement in fluidSubsonic/sonic/ultrasonic wave measurementSound sourcesRound face

The invention discloses a directive near-field measurement data processing method for a round-face piston radiator. The method comprises the following steps: 1, obtaining complex sound pressure data of a measurement plane through a linear array formed by a hydrophone, wherein the measurement plane passes through a near-field region of the round-face piston radiator and is perpendicular to a sound axis direction; 2, enabling the hydrophone to move a delta d distance in the sound axis direction, and obtaining the complex sound pressure data of the measurement plane which is the delta d distance far; 3, obtaining a mass point vibrating speed of a secondary sound source through the complex sound pressure data obtained at step 1 and 2 and finite difference; 4, obtaining the sound pressure of a given point in an external sound field of the measurement plane. The method is simple in data processing, is easy to implement, is small in amount of measurement data, is high in measurement efficiency, and is simple in measurement structure.

Owner:HARBIN ENG UNIV

The Shortest Distance Sorting Method Supplemented by Jipin Coding Method and Internal Sorting Method for Digital Mapping

InactiveCN102467573BSave field timeReduce workloadMaps/plans/chartsSpecial data processing applicationsShortest distanceJoin point

The invention discloses a minimum distance sorting method assisted by a digital mapping brief spelling coding method and an internal sorting method, which is directly applied in the technical field of the total field digital mapping. The brief spelling coding method is composed of a type code+ (a series number)+ (a descriptor)+ (a feature code)+ (-an attribute code)(contents in the brackets are selectable), wherein the measured data is sorted by the minimum distance sorting method assisted by the brief spelling coding method. The minimum distance sorting method is as follows: sequentially calculating distances between the base point and the rest points from the starting point of the surface feature data point and taking the starting point of the surface feature data point as the base point, and selecting the data point with the shortest distance as the connection point with the base point, and taking the selected point with the shortest distance as the base point again, and sequentially calculating the distances between the base point and the rest points, and selecting the data point with the shortest distance as the connection point with the base point, and repeating the steps until no rest points are left; finally, sorting the data points with the shortest distances from each selection based on the precedence such that the sequence fully ensures the connection relationship between each surface feature data point and the other points. The minimum distance sorting method can achieve full automation on field mapping fast coding and interior data processing and map making.

Owner:王尚奇 +1

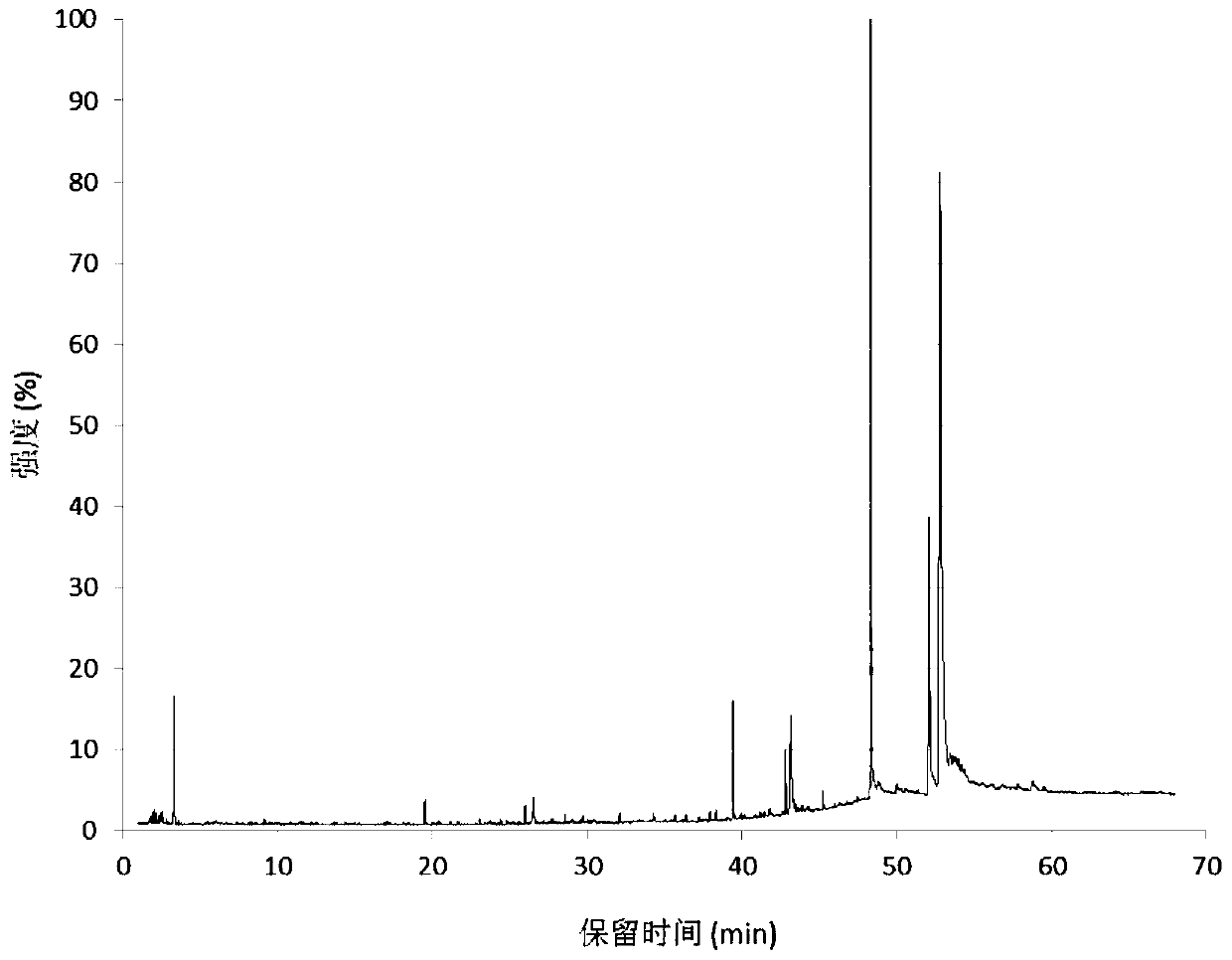

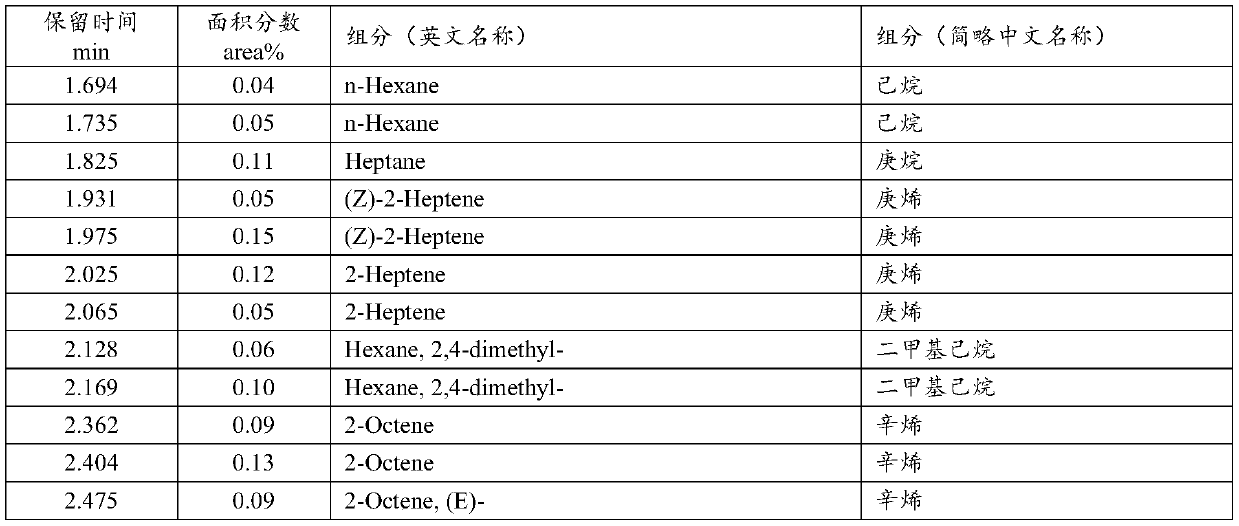

Waste animal and vegetable fat hydrogenation product composition analysis method

ActiveCN110412152ALow priceEasy to operateComponent separationReduction treatmentPretreatment method

The invention belongs to the technical field of oil product composition analysis, and particularly relates to a waste animal and vegetable fat hydrogenation product composition analysis method. The method comprises the following steps of carrying out viscosity reduction treatment on a sample; carrying out sample analysis by using a gas chromatograph-mass spectrometer, wherein the gas chromatography adopts a modified polyethylene glycol capillary chromatographic column; and performing data processing to obtain a sample composition result. The method utilizes the one-dimensional gas chromatography-mass spectrometer and the modified polyethylene glycol capillary chromatographic column for realizing efficient analysis of main components contained in a to-be-detected sample. The method has theadvantages that the operation error possibly introduced in the complex sample pretreatment process is avoided, or different influences on the test result caused by different pretreatment methods and conditions are avoided, and the used instrument is universal and easy to obtain and low in cost, so that the analysis method is suitable for popularization.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

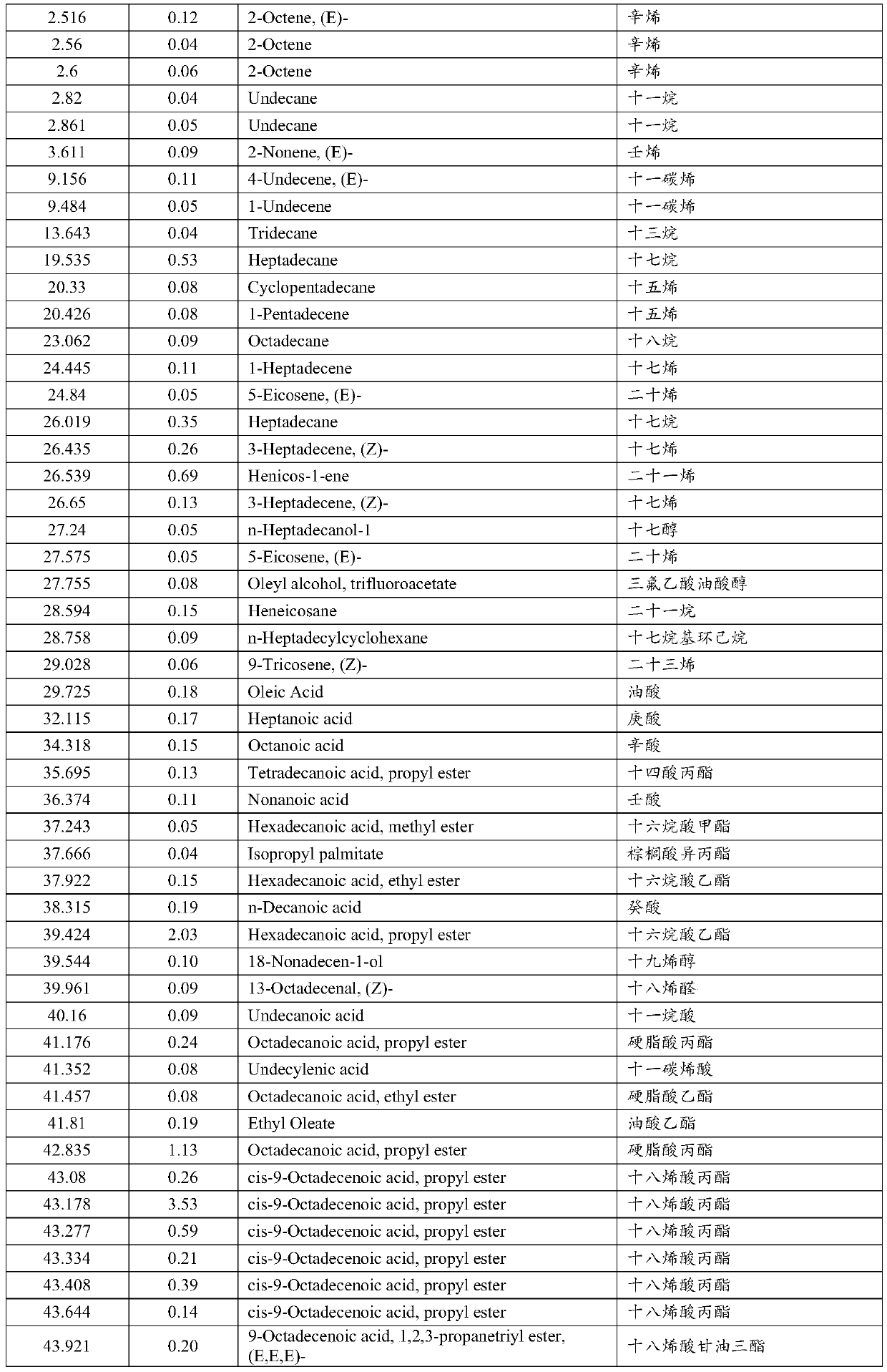

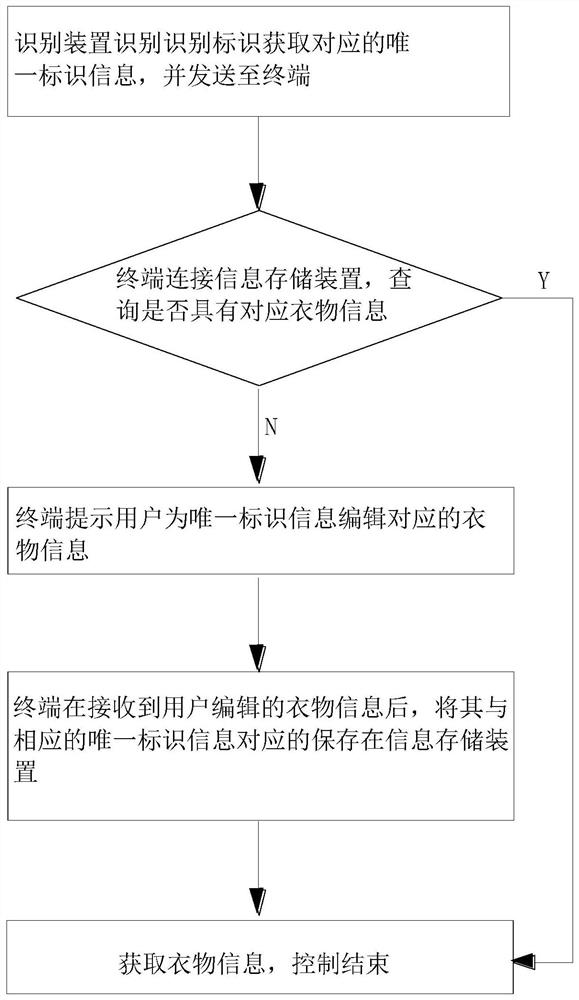

A control method for clothing information management system

ActiveCN110009068BEasy to storeReduce storage capacityCo-operative working arrangementsInformation processingEngineering

The invention discloses a control method of a clothing information management system. The clothing information management system includes an identification device, a control device, a storage device, an information editing device, and an identification mark on the clothing. The control method includes: the identification device identifies The identification mark obtains its unique identification information, the information editing device edits the clothing information for the unique identification information, the control device performs information processing on the edited clothing information, generates a clothing information code with a set format, and the clothing information The information code and the corresponding unique identification information are correspondingly stored on the storage device. In the present invention, the user freely inputs clothing information through the information editing device, and the control device selects keywords according to the clothing information input by the user, and selects the clothing information of each clothing. attribute information, without the need for the user to input clothing information in a specified format, which facilitates the user to edit clothing information, and intelligently selects the required clothing information from the clothing information edited by the user.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE +1

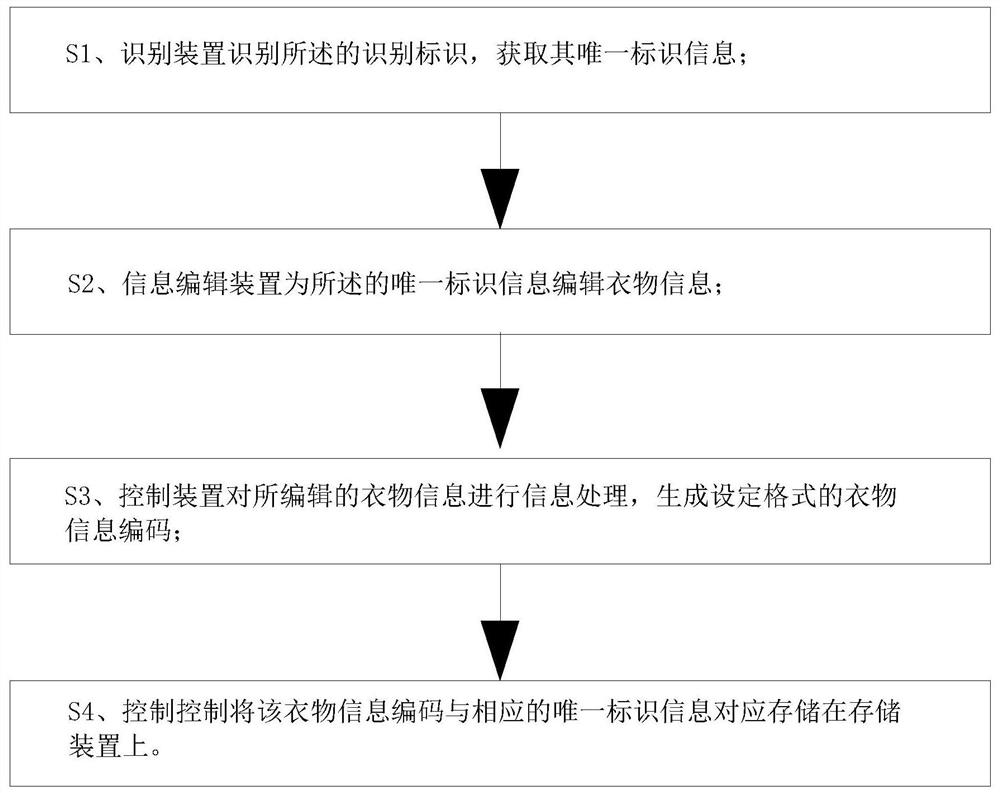

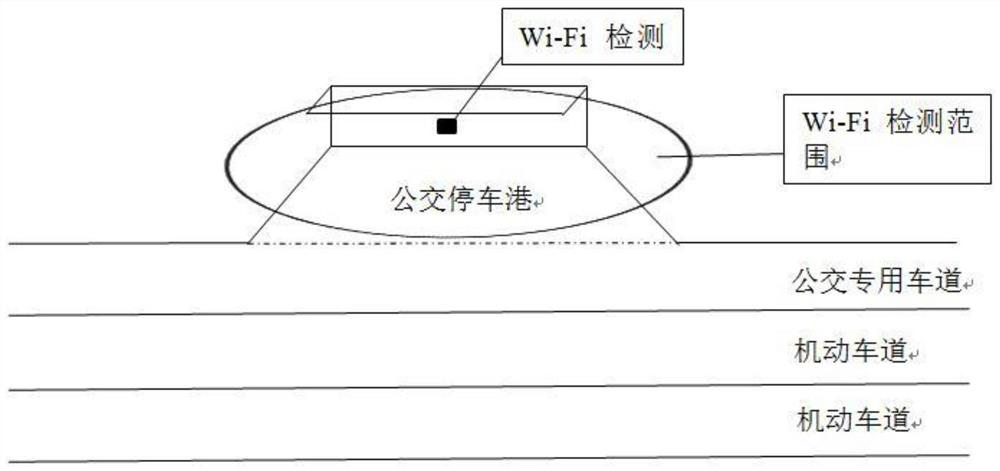

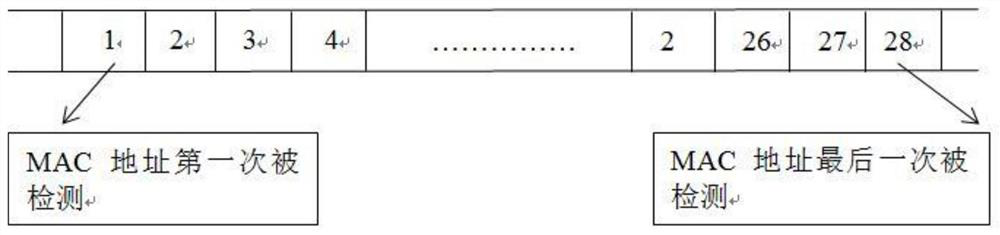

Bus passenger flow prediction method based on vehicle GPS and station wifi

ActiveCN107844856BReduce in quantityHigh precisionForecastingSatellite radio beaconingStationIn vehicle

The invention provides a method for predicting the number of passengers on a bus based on vehicle-mounted GPS and site WiFi. The WiFi detection device arranged at the site detects the MAC address signal of a mobile terminal with a WiFi function near the site at a predetermined frequency, combined with the vehicle-mounted GPS system. The real-time position information of the bus is obtained, and the matching model of the detection time of passengers getting on and off the bus and the bus stop time are established, the interference data near the station is screened out, and the real-time passenger number when the bus leaves the station is accurately predicted; the present invention greatly reduces It reduces the amount of interference data, simplifies the data processing method and improves the accuracy of the data processing results, and accurately predicts the real-time number of passengers when the bus leaves the station; it can provide real-time bus congestion information for passengers waiting for the bus, and provide public travel and The organization and deployment of the urban traffic system, the optimization of the departure frequency, and the real-time monitoring of vehicle passenger flow provide key information references.

Owner:SOUTHEAST UNIV

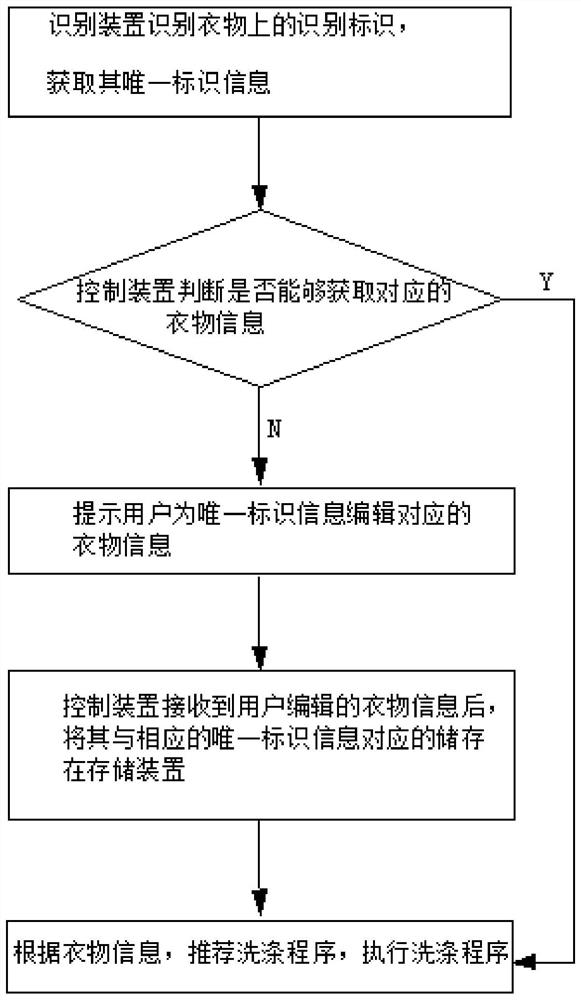

A control method for a clothes processing system

ActiveCN110004637BMeet actual needsImprove accuracyControl devices for washing apparatusTextiles and paperInformation controlSoftware engineering

The invention discloses a control method of a clothing processing system. The clothing processing system includes a washing device, a control device, an identification device, a storage device, and an information editing device. Clothes are provided with an identification mark, and the identification device identifies and obtains a unique identification of the identification mark. information, the information editing device receives the information edited by the user, the control device processes and generates the clothing information code corresponding to the unique identification information and stores it in the storage device; The corresponding relation of the information code acquires the clothes information from the storage device, and recommends the corresponding washing program according to the clothes information, and the washing device executes the corresponding washing program. In the present invention, the user can edit the clothing information corresponding to the unique identification information by himself, and the control device recommends a washing program after processing and storing, which not only makes the editing of the clothing information more flexible and intelligent, but also makes the recommended washing program more optimized.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

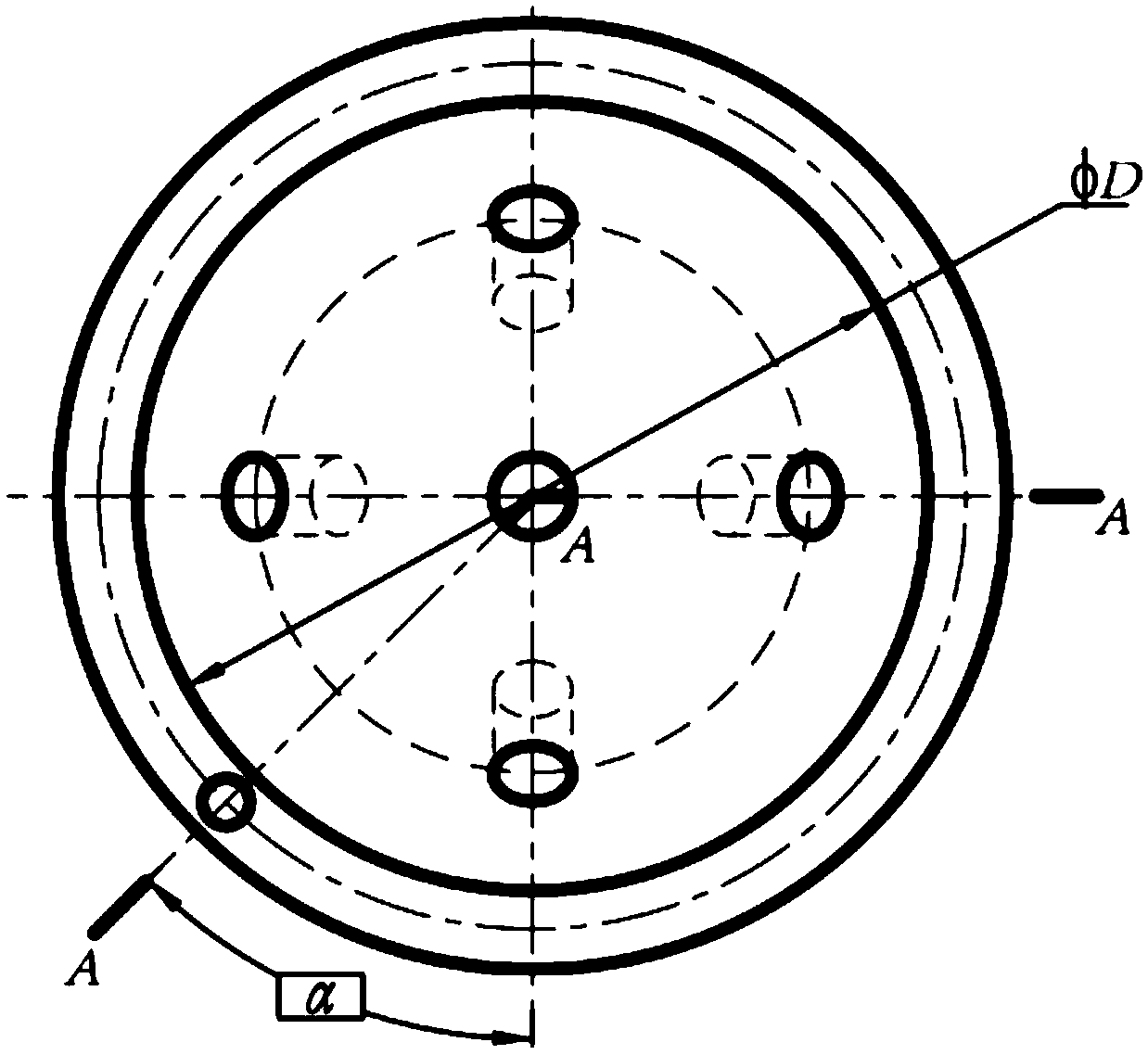

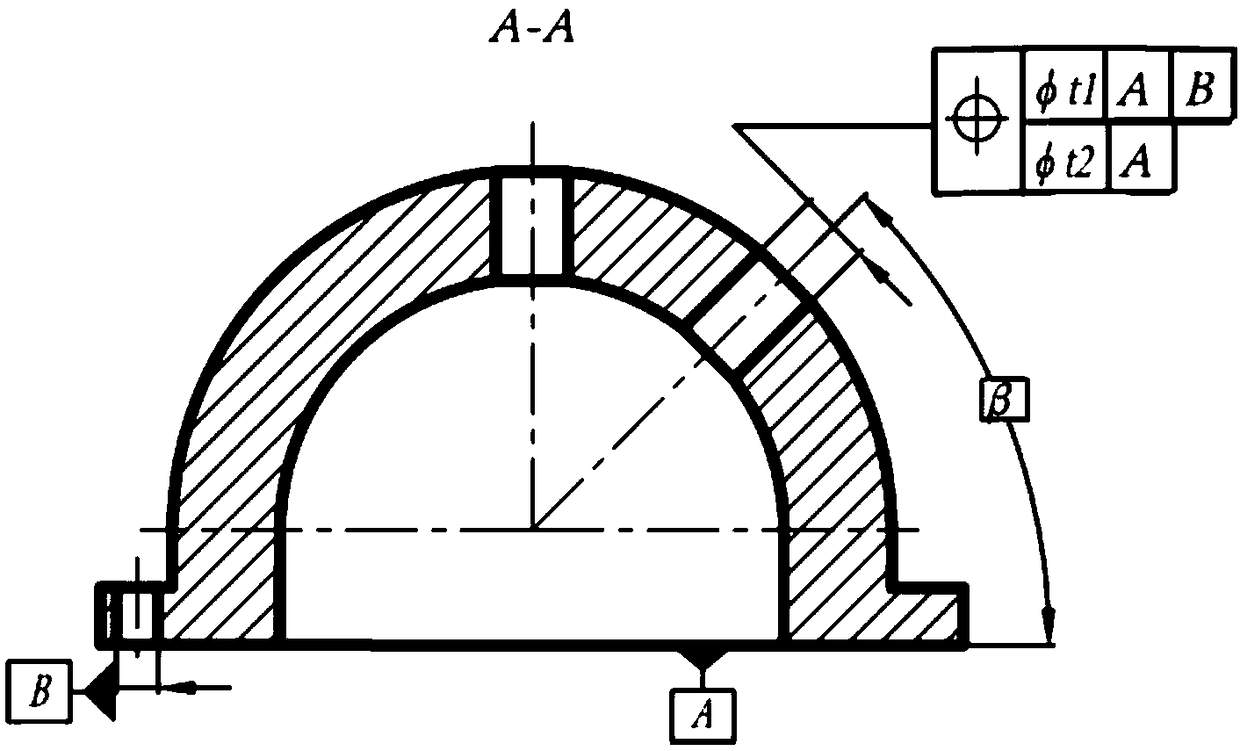

A method for detection and evaluation of compound position error of spherical hole system

ActiveCN106568365BAccurately solve the relative position errorSolve spatial variable problemsMechanical clearance measurementsLower limitAlgorithm

The invention discloses a method for detecting and evaluating a spherical hole composite location degree error, which comprises the steps of respectively calculating the distance between upper and lower limit points on a fitting axis of each hole and an ideal axis, acquiring the maximum distance, and enabling the maximum distance to be multiplied by 2 so as to act as a first error result of the composite location degree error, that is, an absolute location degree error; and acquiring the location of a minimum containing cylinder, sequentially calculating the distance between actual coordinates of all measuring points to an axis of the minimum containing cylinder, finding out the axis location of the minimum containing cylinder through an optimization algorithm, enabling the maximum distance between all of the points to the axis of the minimum containing cylinder to be the minimum, enabling the maximum distance to be multiplied by 2 so as to act as a second error result of the composite location error, that is, a relative location degree error. The method disclosed by the invention solves a problem that a plurality of space variables exist in solving the spherical hole composite location degree error; a relative location degree error between hole groups and a location degree error of each hole relative to the reference in the spherical hole composite location degree can be accurately solved; and an evaluation error in the detection process can be reduced.

Owner:TIANJIN UNIV

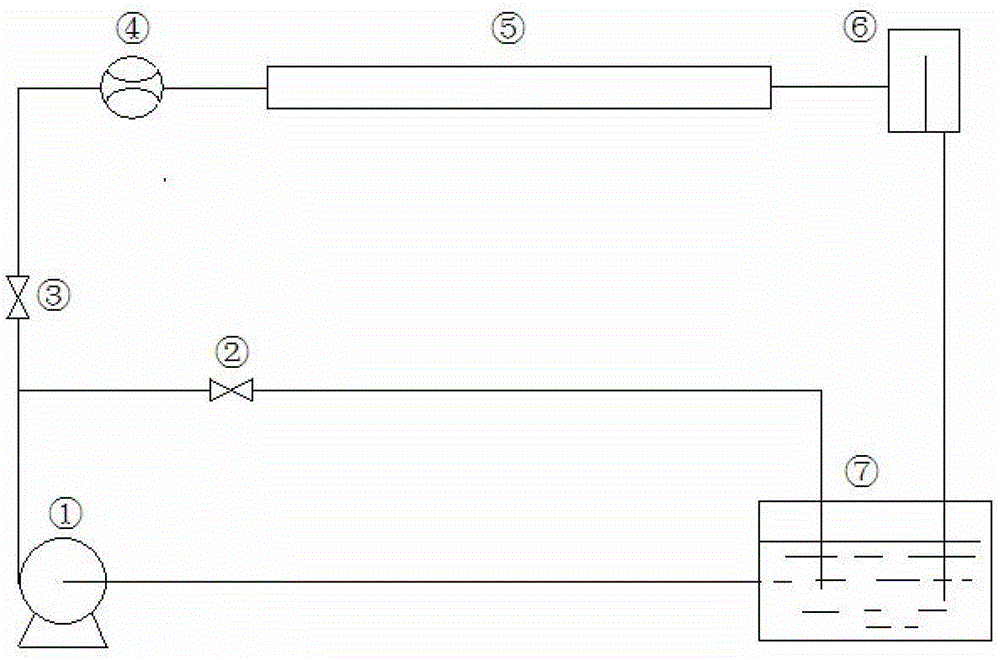

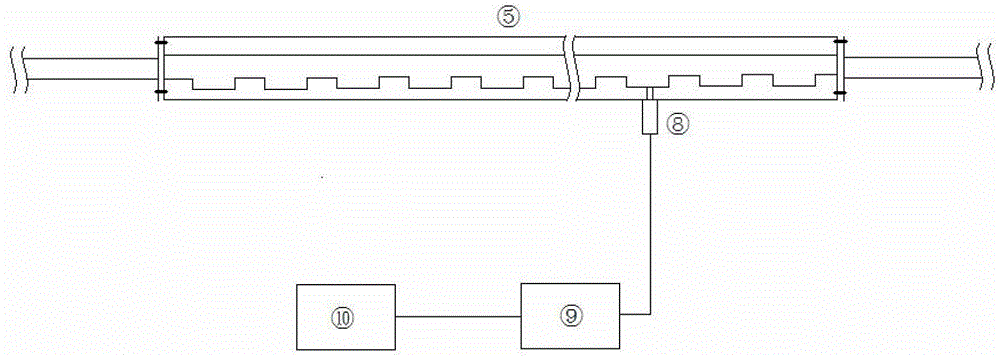

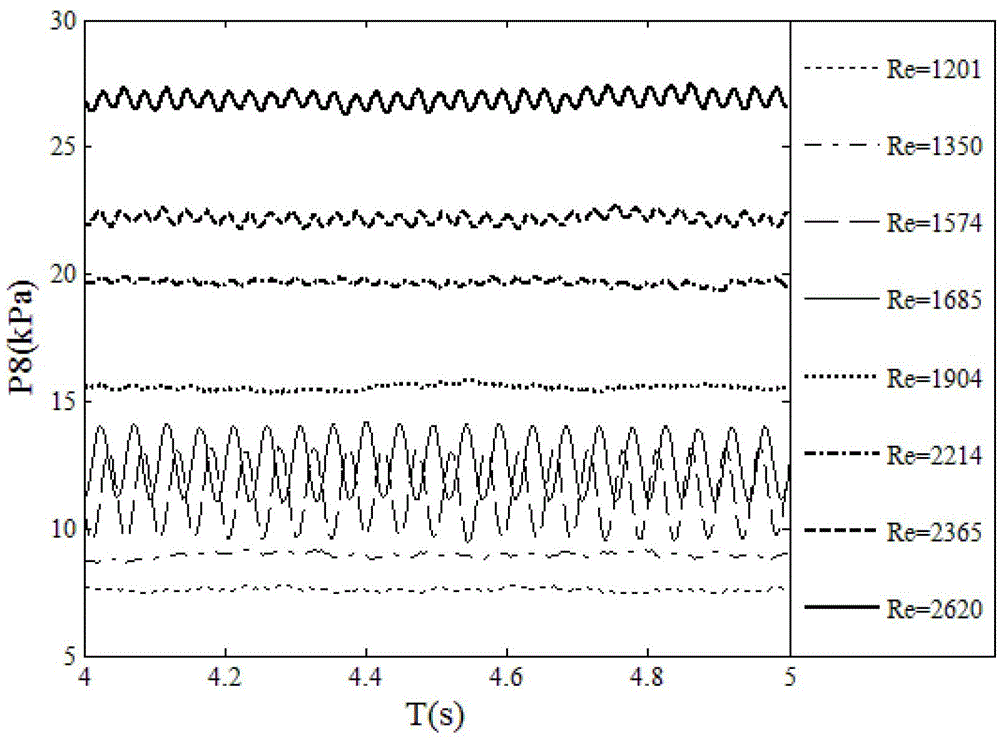

Method for measuring tollmien-schlichting (T-S) waves in two-dimensional fluid passage based on local pressure

InactiveCN103076080BLow costThe data processing method is simpleVibration measurement in fluidS-waveFully developed

The invention discloses a method for measuring tollmien-schlichting (T-S) waves in a two-dimensional fluid passage based on local pressure, and belongs to the technical field of flowing test. The method comprises the following steps of: connecting a circulating water pump and a flow meter to a circulation system of the two-dimensional fluid passage to be tested, establishing a self-circulating flowing system, arranging a pressure sensor in a contact way on the wall surface of the two-dimensional fluid passage, and drilling a hole leading to the interior of the fluid passage in the center of a contact surface; connecting the pressure sensor with a computer data acquisition system; enabling fluid in the fluid passage when entering the two-dimensional fluid passage through a measurement system pipeline to enter in a gradually varied flow form, and forming stable fully developed flow after the fluid passes through a flow stabilization inlet; and recording local pressure signals varied along with time under different flowing Reynolds numbers, and performing processing according to the time history of the local pressure to obtain the natural frequency and the amplitude of the T-S waves. Lower-order to higher-order T-S waves can be measured in any two-dimensional fluid passage, used related equipment is low in cost and convenient to popularize, and a data processing method is simple, intuitive and easy to master.

Owner:DALIAN UNIV OF TECH

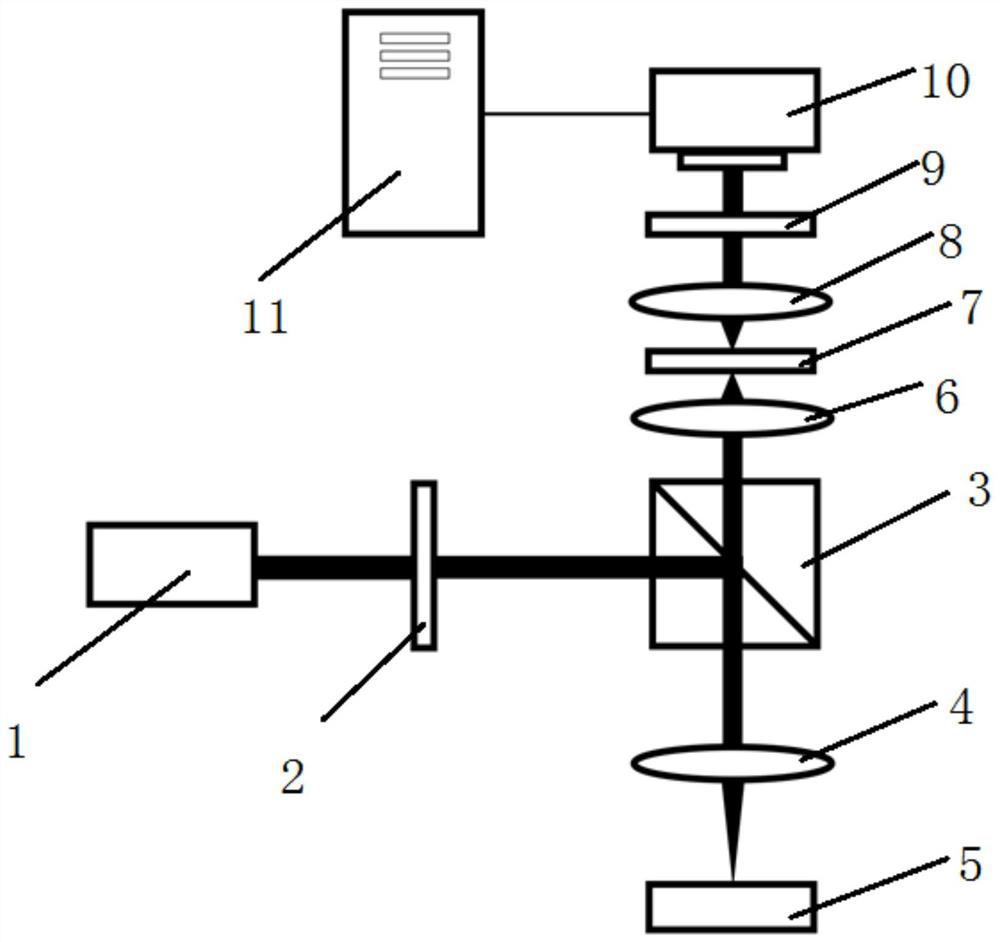

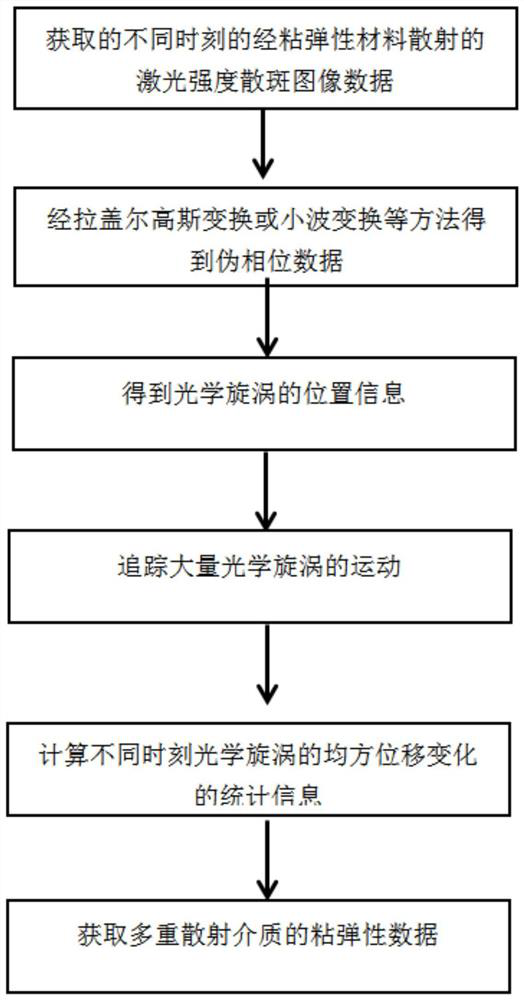

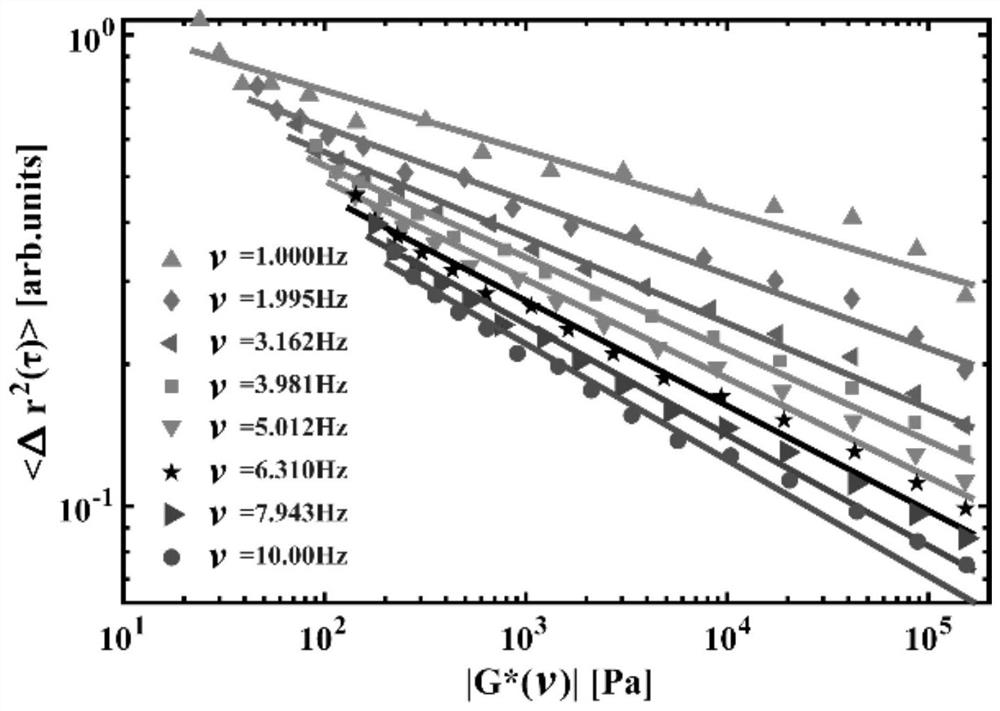

Device and method for optical micro-rheology for characterizing viscoelasticity of soft substance

PendingCN112748042ASimple structureThe data processing method is simpleIndirect flow property measurementLaser lightLaser intensity

The invention discloses a device and a method for optical micro-rheology for characterizing the viscoelasticity of a soft substance. Coherent light generated by a laser light source is focused by a lens and irradiated on a sample to be detected in a sample cell, and a dynamic laser intensity speckle image sequence formed by scattered light after the sample to be detected is scattered is collected by a camera and transmitted to a computer for processing. And mathematical transformation is carried out on the obtained speckle light intensity diagrams of a material to be detected at different moments to obtain a pseudo-phase diagram of the speckles, and optical vortex position information can be obtained through the pseudo-phase diagram. Statistical information of mean square displacement of the optical vortex in unit time at different moments is obtained through calculation by tracking random motion of the optical vortex, and information for characterizing the viscoelasticity of the material to be detected is finally obtained through the corresponding relation between the viscoelasticity of the material to be detected and the mean square displacement of the vortex point. A measuring system is simple, only a trace sample is needed, particle movement in the sample does not need to be tracked, and high-frequency response which cannot be obtained by a traditional rheometer can be obtained.

Owner:HUAZHONG UNIV OF SCI & TECH +1

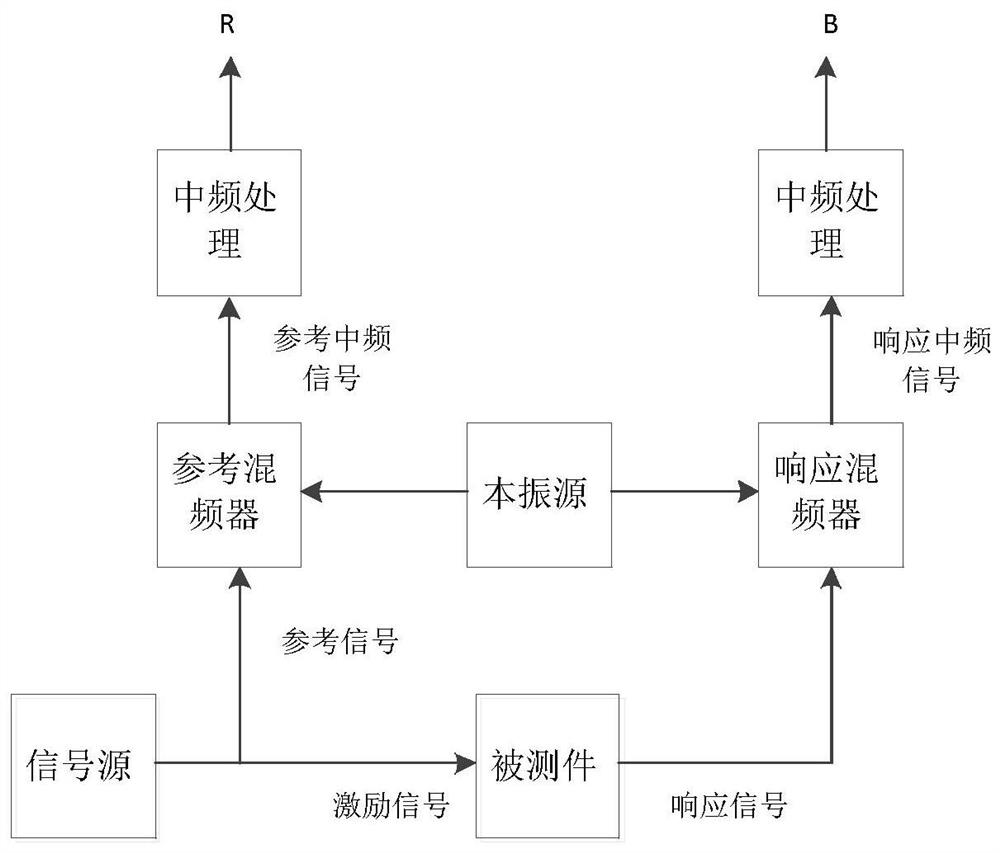

A Method of Improving Phase Accuracy of Vector Network Analyzer Scanning Test

ActiveCN110542906BSolve the problem of inaccurate phase resultsWill not test speed impactElectrical testingElectromagnetic wave reradiationIntermediate frequencyFrequency measurements

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

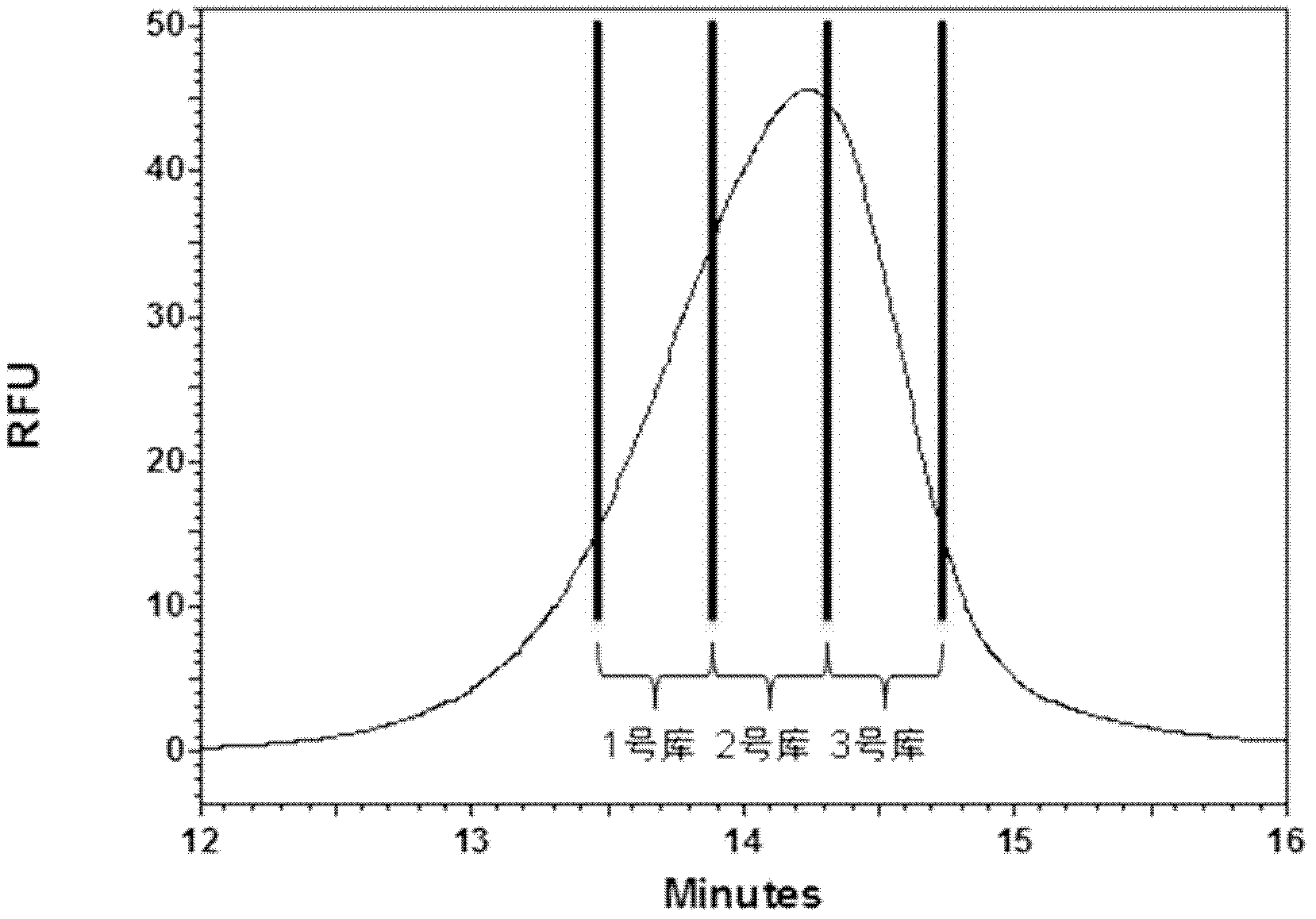

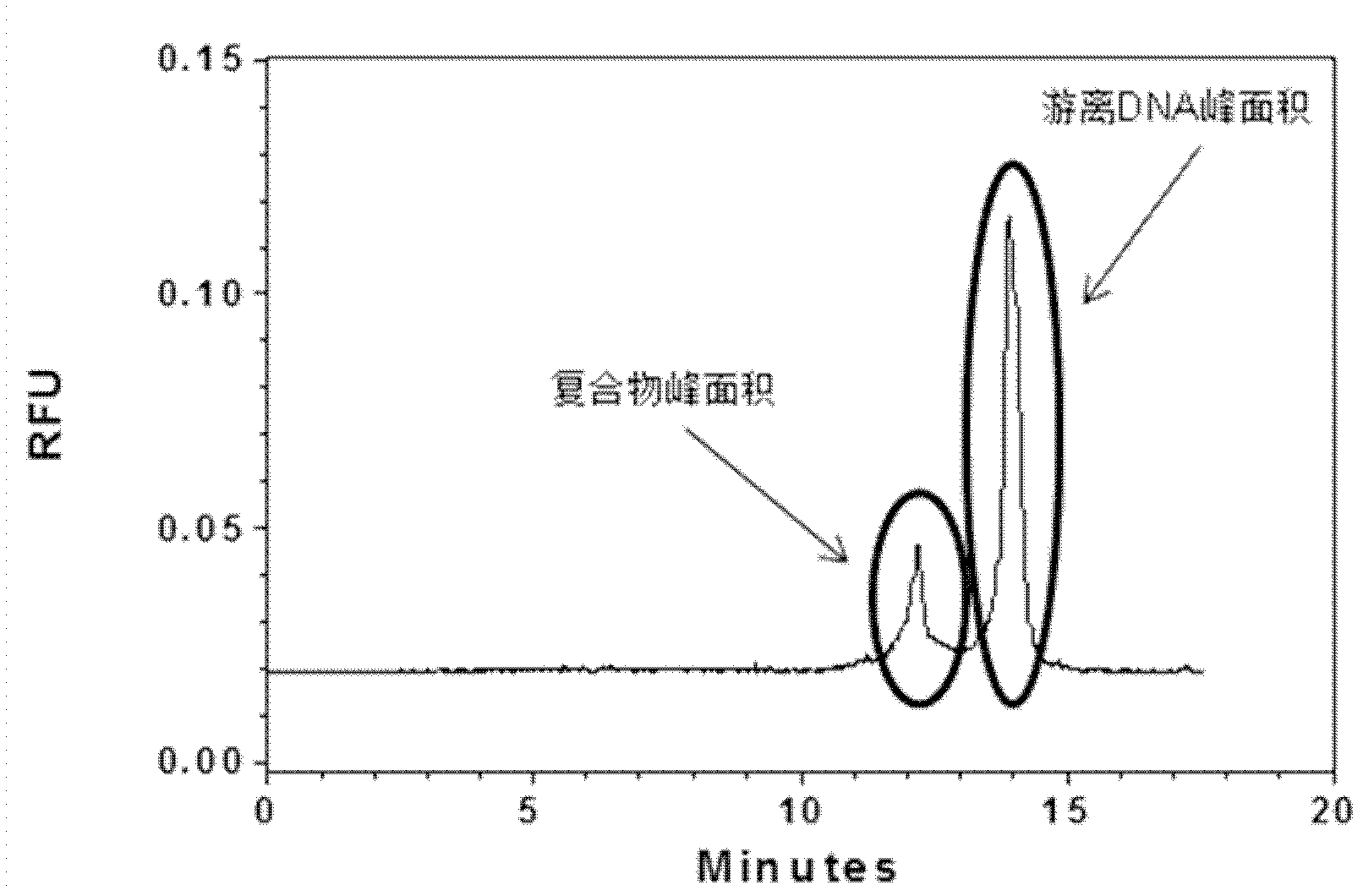

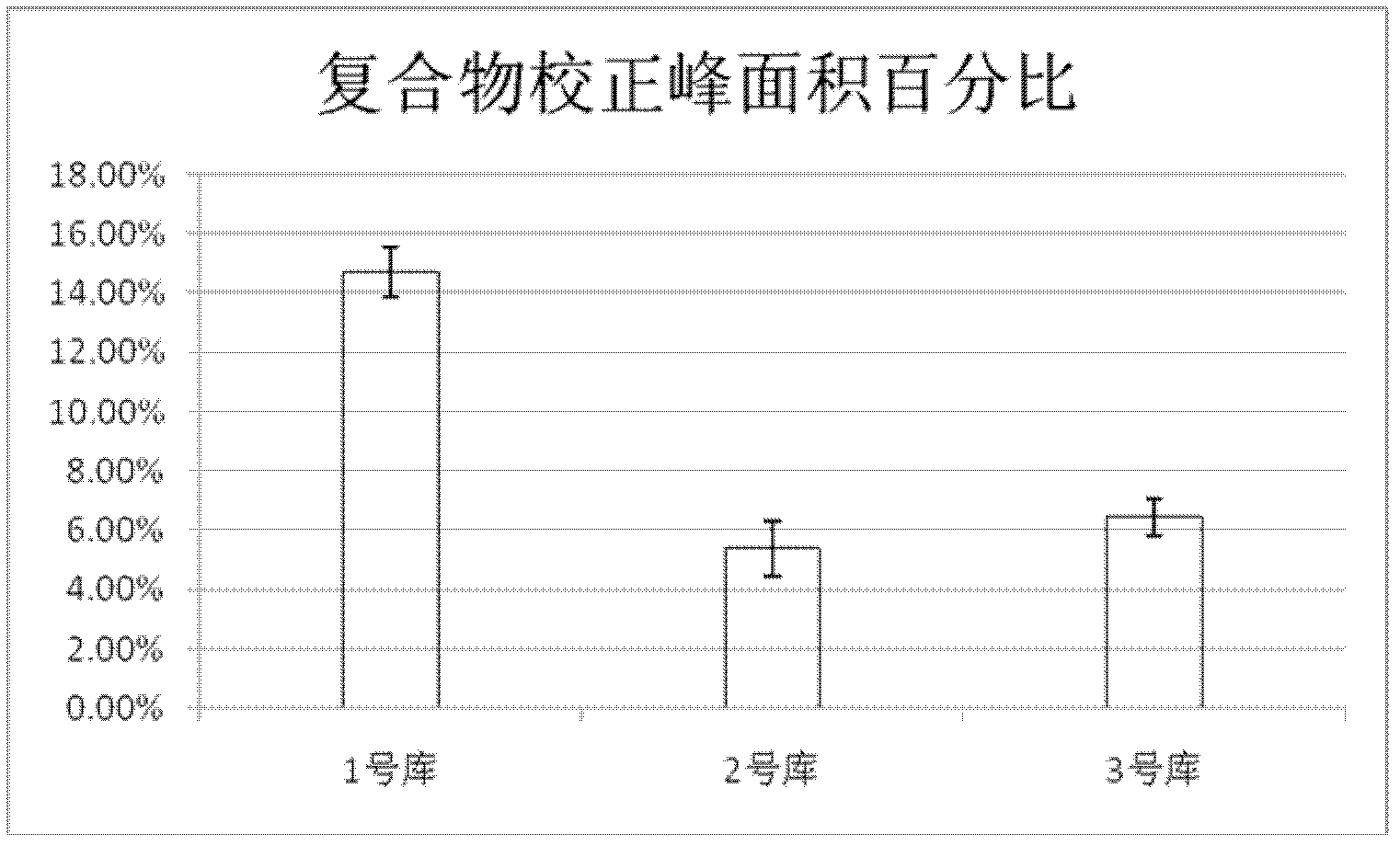

Oligonucleotide library classification and assessment method based on capillary zone electrophoresis

InactiveCN102636547BReduce filter rangeShort screening cycleMaterial analysis by electric/magnetic meansTime rangeCapillary electrophoresis

The invention discloses an oligonucleotide library classification and assessment method based on capillary zone electrophoresis, and belongs to the field of creature isolation analysis. The method comprises the following steps of: step one, carrying out capillary zone electrophoresis on an oligonucleotide library, and obtaining a secondary library within an oligonucleotide library electrophoresis time range according to transfer time slicing collection; and step two, respectively mixing each secondary library with a homogeneous target molecule, carrying out capillary zone electrophoresis, and comparing the strong or weak of each secondary library and target molecule interaction, thus obtaining the strongest secondary library of the target molecule combining capacity. The classification and assessment method can be used for realizing the fractionation of complicated constituent oligonucleotide library, and obtaining the strongest secondary library of the target molecule combining capacity; and the strongest secondary library of the combining capacity is utilized as a next CE (capillary electrophoresis)-SELEX(systematic evolution of ligands by exponential enrichment) technical screening library, the screening range is reduced, and the screening period of an adaptation body is shortened.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

An eddy current detection device and method for coating thickness of galvanized sheet for automobiles

InactiveCN105300266BHigh precisionAvoid measurement errorsElectrical/magnetic thickness measurementsElectricityAfter treatment

The invention discloses an eddy current detection device for the coating thickness of a galvanized sheet for automobiles, comprising an eddy current probe, an impedance analyzer, a fixture for fixing a tested piece and a computer; the eddy current probe is placed on the surface of the tested piece, Generate a sinusoidal excitation signal through the impedance analyzer, drive the eddy current probe to generate the excitation magnetic field, and also generate the eddy current magnetic field inside the test piece. The change is converted into an electrical signal and fed back to the impedance analyzer to obtain the inductance value. After the inductance value is processed by the zinc coating thickness detection data model established by the computer, the thickness of the coating of the tested piece can be obtained; at the same time, a device using the device is disclosed. In the detection method, the present invention selects the inductance value as the characteristic parameter of thickness measurement, improves the thickness measurement range and sensitivity, can realize fast and accurate online detection of the coating thickness of galvanized sheet, and has great potential economic benefits.

Owner:CHINA UNIV OF MINING & TECH

High-speed loading material dynamic indentation experimental method

InactiveCN103018123BHigh measurement accuracyStudy dynamic mechanical propertiesInvestigating material hardnessElectricityExperimental methods

The invention discloses a high-speed loading material dynamic indentation experimental method which is characterized by comprising the following steps of: firstly, fixedly arranging a cylindrical tested part on the end face of the front end of a circular section compression bar, adhering a strain gauge to the compression bar and electrically connecting the strain gauge and a high dynamic strain indicator; then fixedly arranging a light-triggered speed measurement device in front of the tested part; launching a shot by a shot lunching device and enabling the shot to pass through the light-triggered speed measurement device to impact the tested part; and finally, obtaining a press-in force, a press-in speed and a press-in displacement time history of the tested part by a relation. The high-speed loading material dynamic indentation experimental method has the advantages that by the experimental method, dynamic mechanical properties (such as the press-in force, the press-in speed and the press-in displacement time history) of the tested part in the impact process can be measured, so that the dynamic mechanical properties of a material are more deeply researched; moreover, the method can be suitable for a higher impact speed; the impact speed can reach 100m / s; and meanwhile, the experimental method has high measurement accuracy and adopts a simple data processing method.

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com