Directive near-field measurement data processing method for round-face piston radiator

A technology of measurement data and processing method, applied in the field of directional near-field measurement data processing of circular piston radiators, can solve the problems of high requirements for scanning and positioning accuracy, no data processing method, and reduced measurement accuracy, etc. The effect of realizing and reducing the amount of measured data and improving the measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

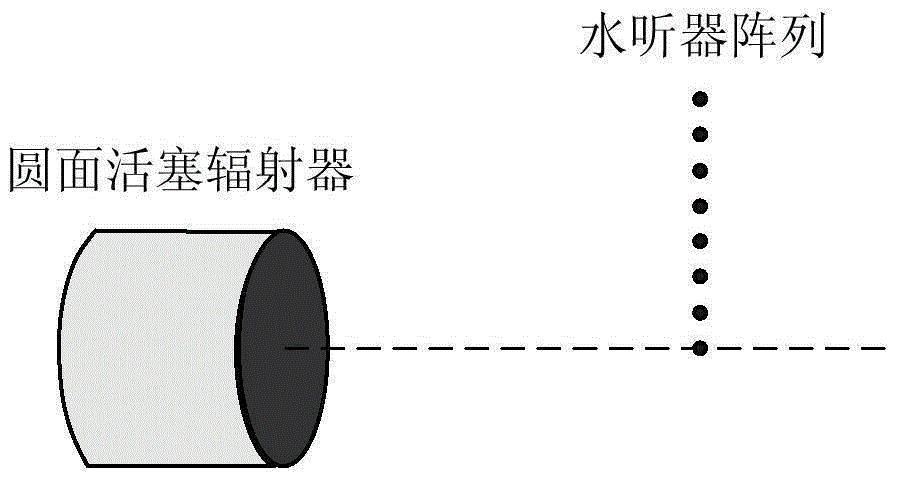

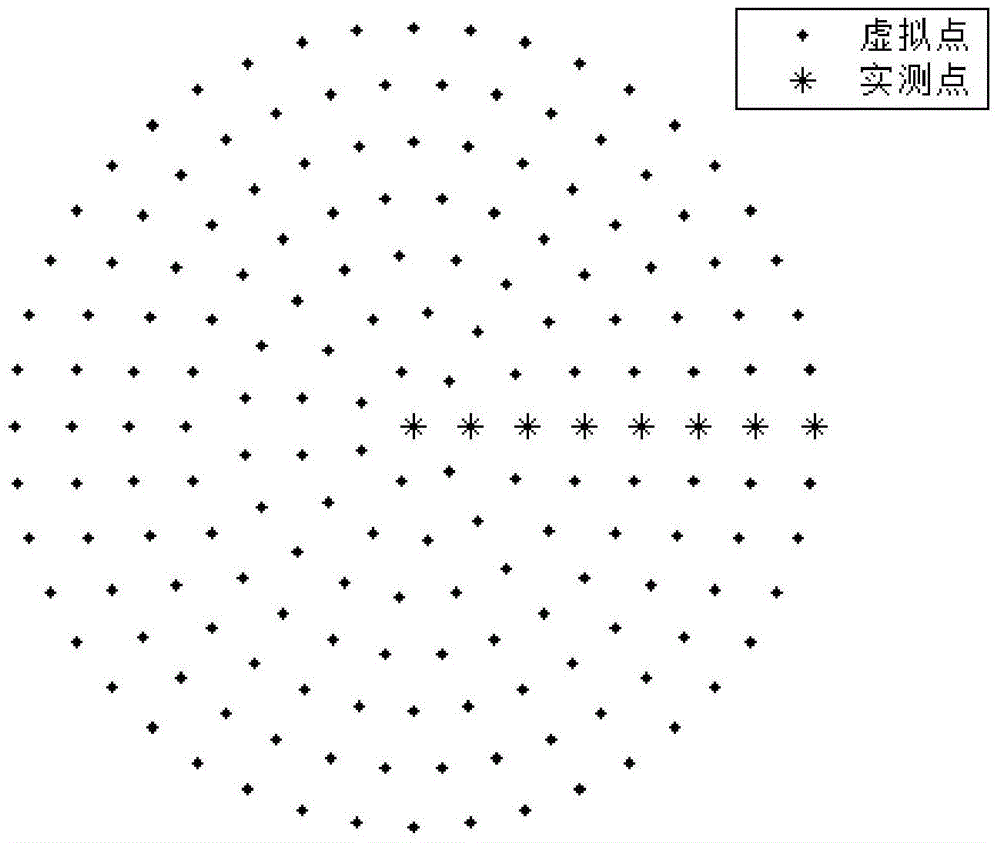

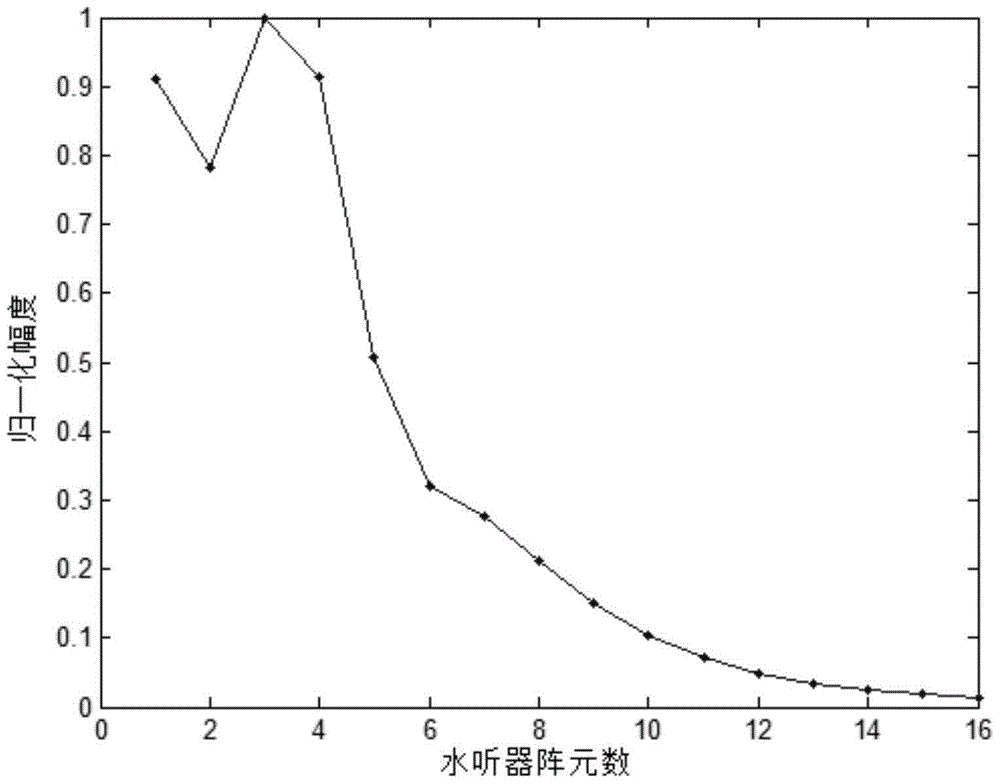

[0049] The radius of the circular piston radiator is 0.05m, the radiated sound wave frequency is 50kHz, the receiving hydrophone is a 16-element linear array, and the element interval of the hydrophone is 0.01m. figure 1 Arranged as shown, the complex sound pressure data received by each hydrophone, and then as figure 2 As shown, on the plane where the hydrophone array is perpendicular to the sound axis, a virtual point of each hydrophone on the corresponding circle is constructed, and the complex sound pressure data of each virtual point is the complex sound pressure at the measured point on the corresponding circle. Compress data. Such as image 3 Shown is the amplitude of the sound pressure signal received by each hydrophone, Figure 4 It is the sound pressure amplitude distribution on a circular surface behind the virtual point, that is, the secondary sound source surface.

[0050] Move the hydrophone array along the sound axis for a distance of Δd=0.001m to obtain com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com