Non-contact type measuring method and device for metal surface coating thickness

A non-contact, metal surface technology, applied in the field of mechanical processing, can solve problems such as coating surface damage, and achieve the effects of easy on-line detection, economic cost and time saving, and simple data processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

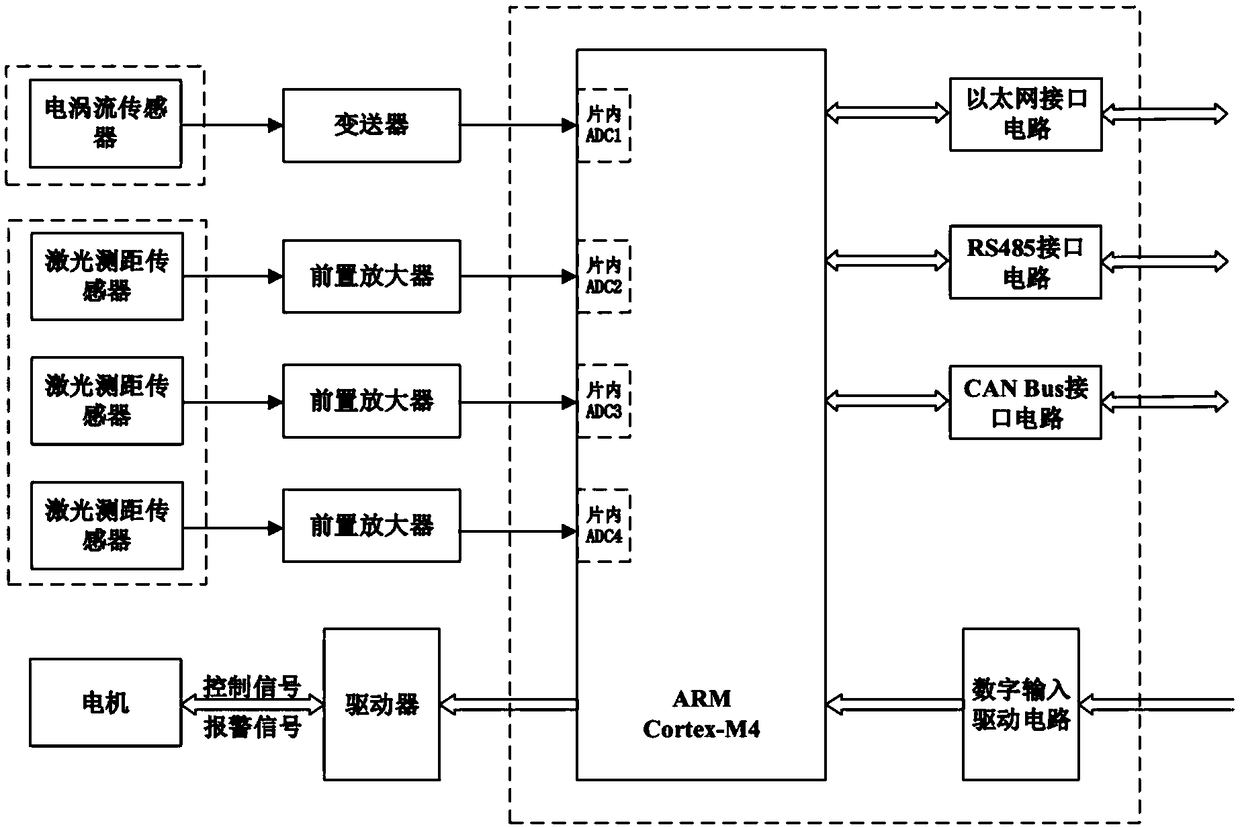

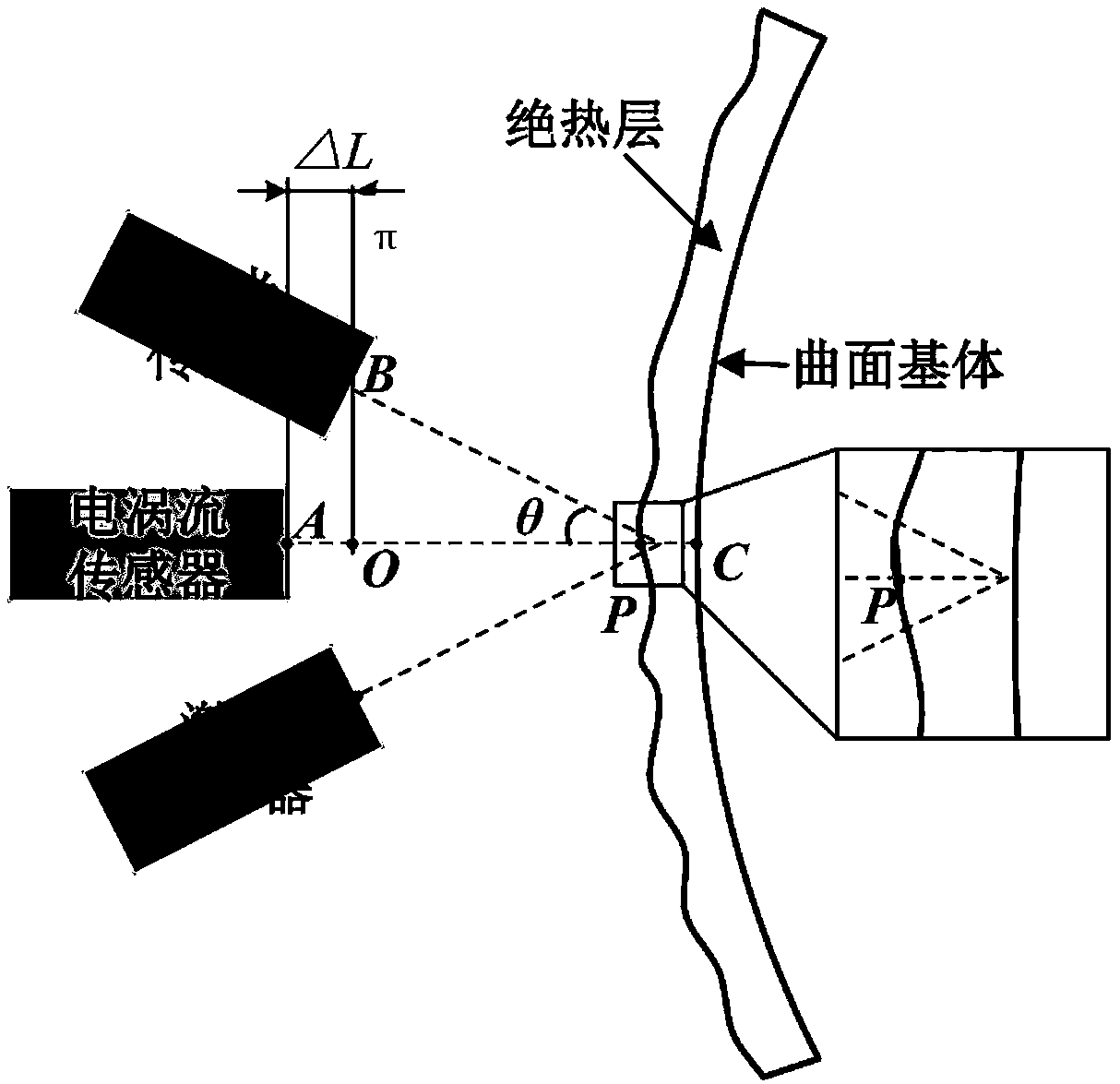

[0024] Such as figure 1 with figure 2 As shown, it is an online measuring device for the thickness of the thermal insulation layer of a cylinder involved in this embodiment, which includes: an eddy current sensor 1, a laser distance measuring sensor group 2, and a main control computing subsystem with a built-in ARM chip circuit connected to it respectively 3. Among them: between the eddy current sensor 1 and the main control computing subsystem 3, there is a transmitter for linearizing and normalizing the displacement signal collected by the sensor, and directly outputting 4 ~ 20mA. A preamplifier for amplifying the voltage signal is provided between each laser ranging sensor in 2 and the main control computing subsystem 3, and the output terminals of the transmitter and the preamplifier are connected with the modulus in the main control computing subsystem 3 respectively. The conversion unit is connected.

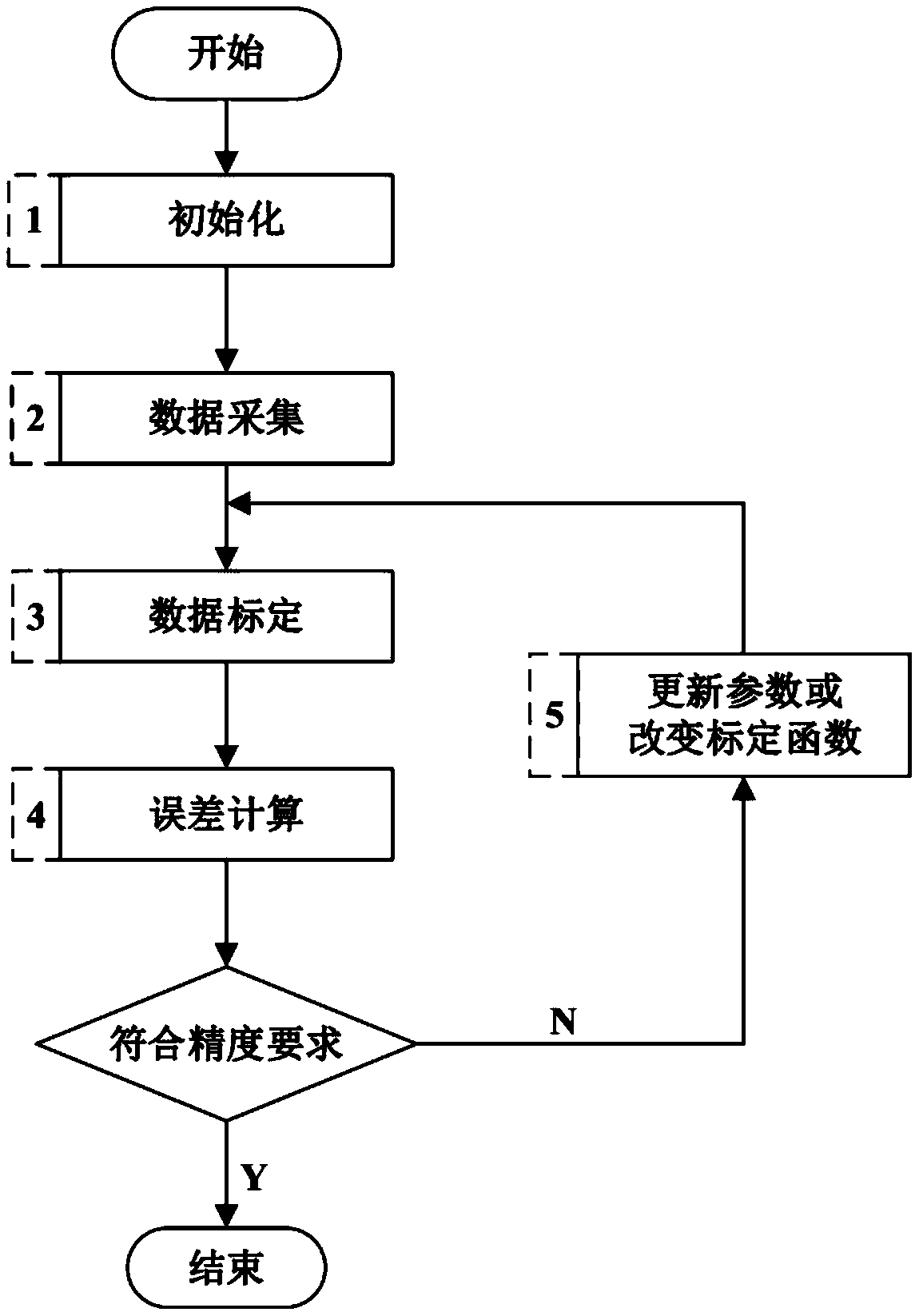

[0025] The ARM chip circuit analyzes and comprehensively processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com