A method for detection and evaluation of compound position error of spherical hole system

A composite position degree and spherical hole technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of difficulty in manufacturing, low yield rate, difficulty in ensuring process accuracy, etc., to achieve reduced evaluation errors, high precision, The effect of simple data processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In order to make up for the shortcomings of the existing method for detecting and evaluating the compound position degree of the spherical pore system, the embodiment of the present invention establishes an error model for the compound position degree of the spherical pore system, and uses a three-coordinate measuring machine as the basic detection instrument to propose a method of coincidence through rotation , which realizes the simple measurement and evaluation of the composite position degree of the spherical pore system, see the following description for details:

[0031] 101: Use a three-coordinate measuring machine to obtain measurement data, that is, point coordinates on multiple sections of each hole;

[0032] 102: Process the measurement data: first, solve the center of each section according to the data points on multiple sections in each hole; then solve the fitting axis of each hole according to the center of the section, and calculate the position of each h...

Embodiment 2

[0039] The scheme in embodiment 1 is introduced in detail below in conjunction with specific description drawings and calculation formulas, see the following description for details:

[0040] 201: Detect object

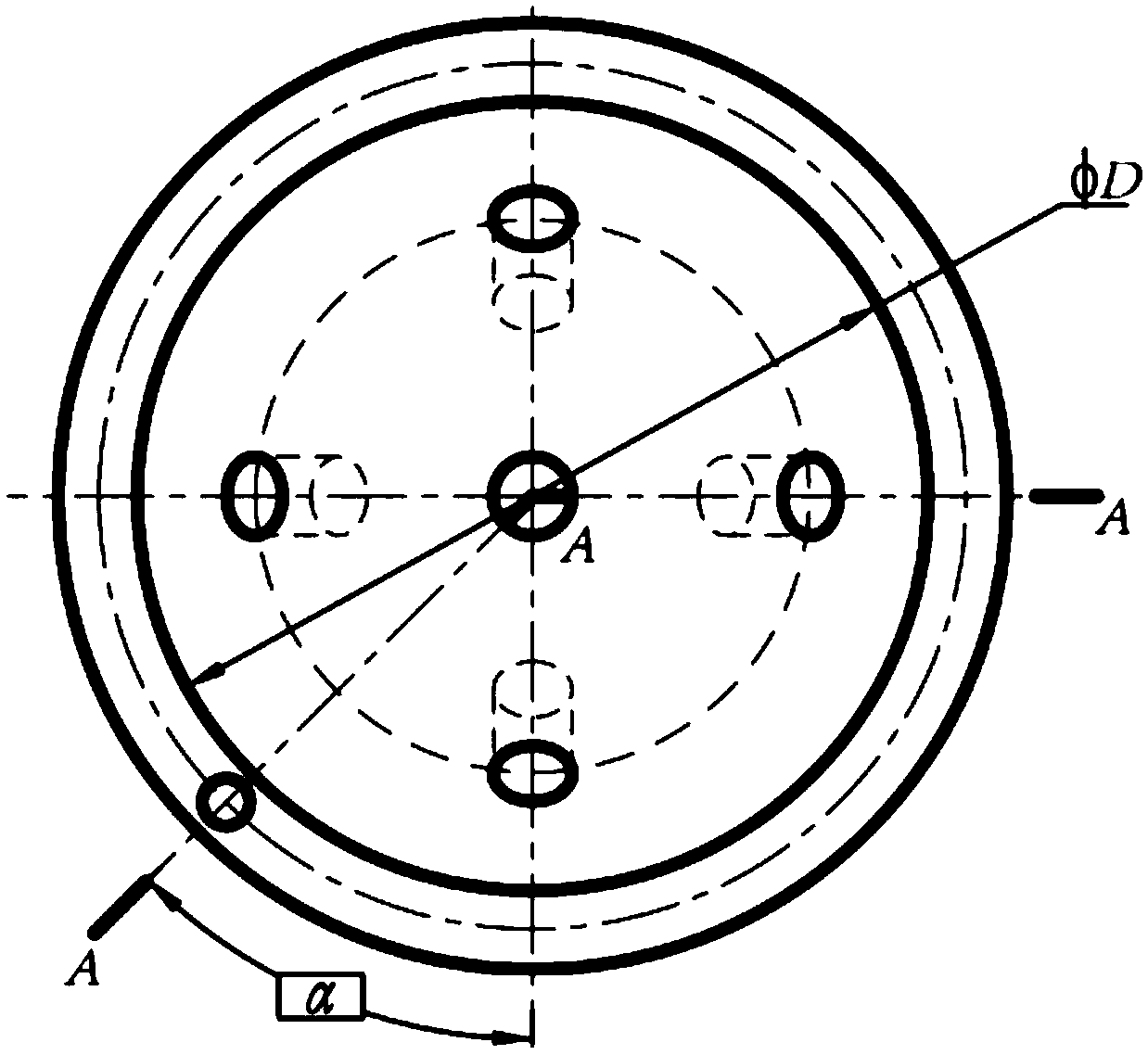

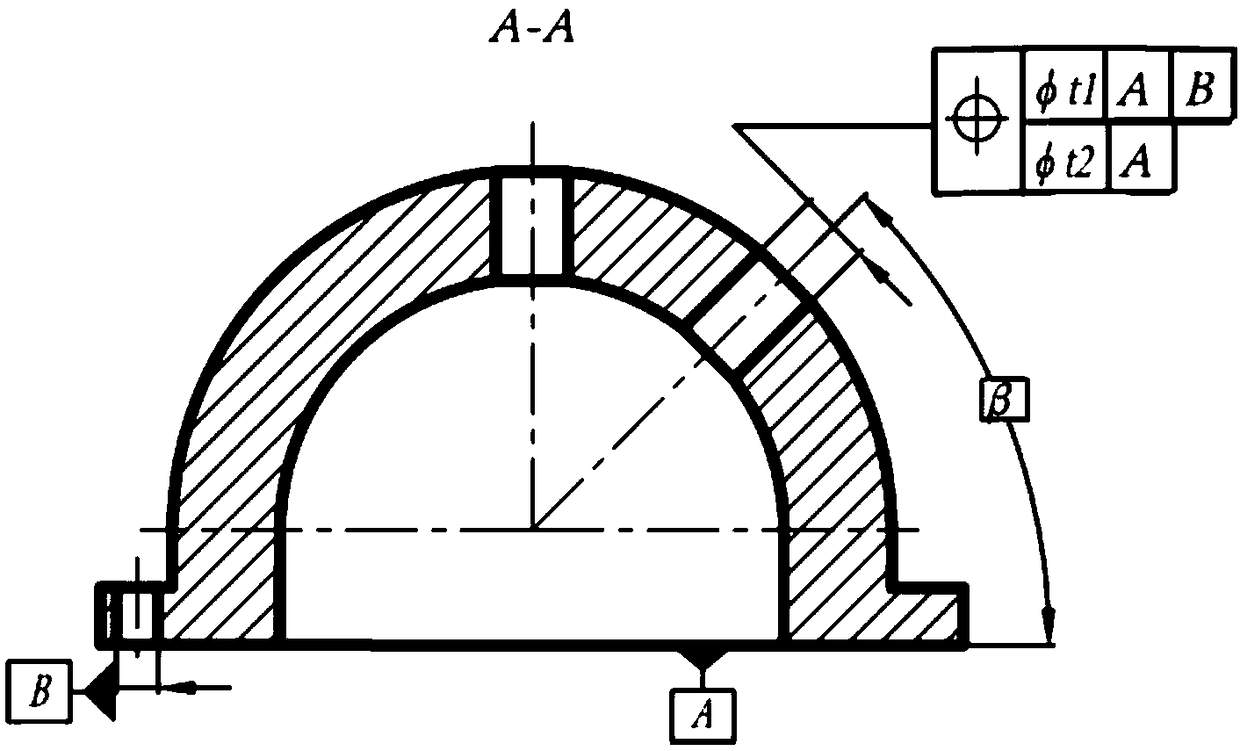

[0041] Among them, the spherical hole system targeted by the embodiments of the present invention is a manufacturing process and features of a group of holes on the spherical surface. like Figure 1a , 1b , 1c are respectively a three-dimensional schematic diagram and a two-dimensional diagram of a part with spherical pores.

[0042] 202: error to be checked;

[0043] The detection and evaluation error item in the embodiment of the present invention is the compound position degree error of the pore system on the spherical surface, which belongs to the compound position degree error category of group features.

[0044] In ASME-14.5 2009 (American Society of Mechanical Engineers Standard), the compound position degree of group features is defined as follows: The comp...

Embodiment 3

[0087] Combined with the specific calculation formula, the solution method of the minimum containing cylinder is given below, see the description below for details:

[0088] The relative position error of the hole group has a position requirement related to the A datum. In order to ensure the position degree requirement with the datum A, the axis of the smallest containing cylinder is perpendicular to the Z axis, and the direction vector of the axis is expressed as (0,0,1). So the points on the fitted axis after the fitting translation and rotation Projection point projected on the XOY plane Converted to solving the smallest enclosing circle, r max Expressed as the radius of the smallest enclosing circle. Therefore, the minimum enclosing circle is very important to ensure the accuracy of the algorithm and the accuracy of the solution. The embodiment of the present invention uses the particle swarm algorithm to accurately and quickly solve the minimum enclosing circle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com