Automatic cleaning and zeroing system for light ion organic volatile gas detector

An organic volatile matter and gas detector technology, applied in chemical instruments and methods, cleaning methods and utensils, instruments, etc., can solve the problems of inconvenient disassembly and maintenance, affecting the accuracy of the detector, and decreasing the sensitivity of the sensor, so as to maintain accurate sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

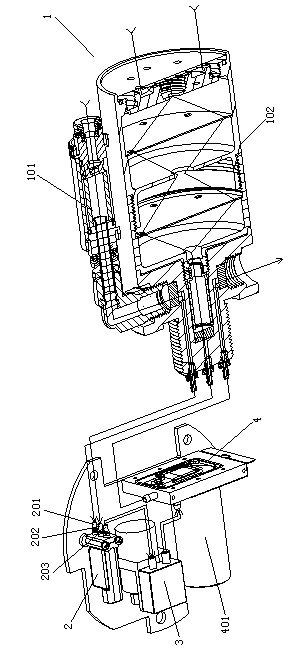

[0010] Such as figure 1 As shown, a photoion organic volatile gas detector automatic cleaning and zeroing system includes a diaphragm air pump 3 installed on the mounting plate, an ion chamber 4 and an ion lamp 401 located in the ion chamber 4, and also includes an air Filter 1, solenoid valve 2 and microprocessor (not shown in the figure) installed on the mounting plate, the solenoid valve 2 is a three-way solenoid valve, including a sample gas sampling channel 202 to be tested, filtered clean air Sampling channel 201 and gas output channel 203; described air filter is made of VOC sampling filter 101 and on-site cleaning and zeroing filter 102, and this VOC sampling filter 101 and on-site cleaning and zeroing filter 102 correspond to a gas output channel respectively , the ambient air passes through the on-site cleaning and zeroing filter 102 to become the sample gas to be tested, passes through the sample gas sampling channel 202 of the three-way solenoid valve, then enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com