Non-destructive evaluation of welded joints of bar wound stator utilizing infrared and thermal methods

A technology for welding joints and welding parts, which is applied in welding/welding/cutting items, welding equipment, arc welding equipment, etc., and can solve problems such as ineffectiveness, inability to provide evaluation of the effective size of the heat-affected zone, and poor electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

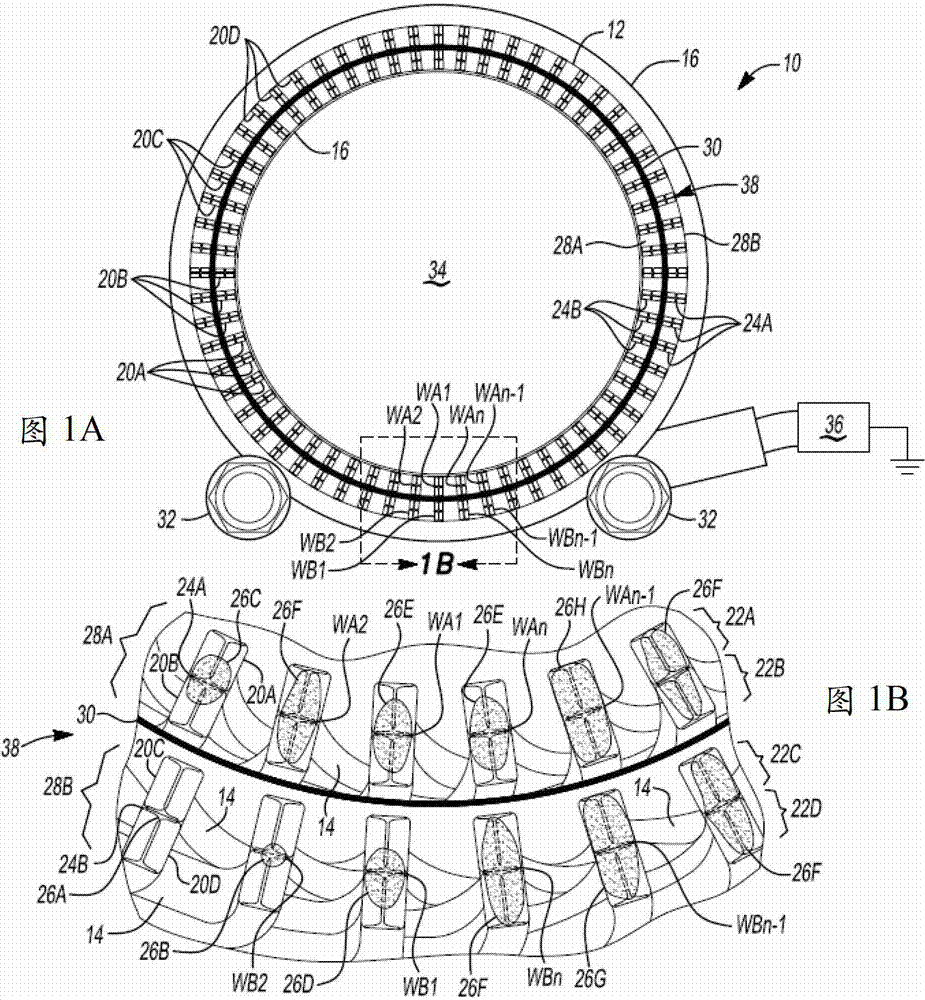

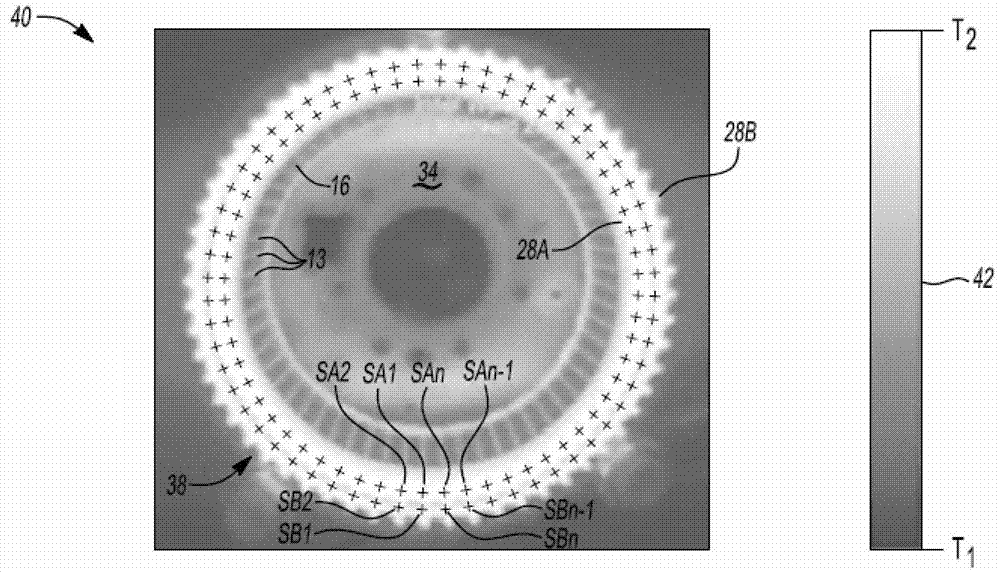

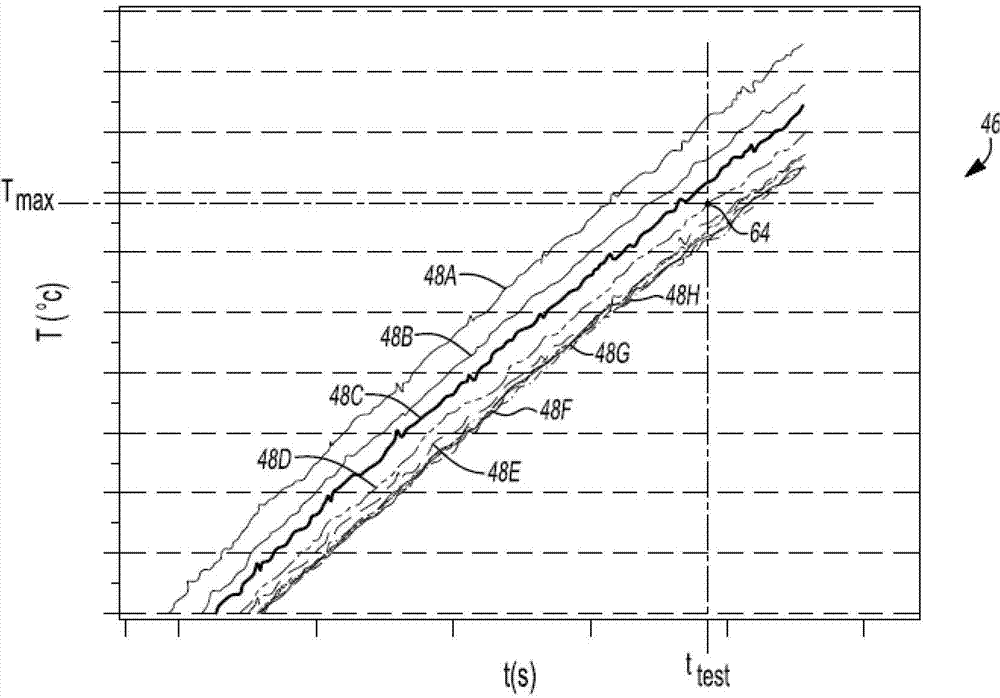

[0026] Referring to the drawings, wherein like reference numerals indicate like parts throughout the several views, the elements shown in FIGS. 1-8 are not to scale. Accordingly, the specific dimensions and applications provided in the figures herein should not be considered limiting. This paper provides a method and system for non-destructive evaluation of stator welds. The stator assembly may be configured as a bar wound stator including a plurality of bar pins, each bar pin including one or more wire ends positioned relative to another wire end to form a plurality of wire end pairs. Each end pair is connected by a solder portion that forms a solder joint between the wire ends of each end pair. The quality of one or more of the plurality of welded joints connecting corresponding pairs of wire ends of a bar wound stator can be evaluated and determined using the non-destructive evaluation methods and systems described herein.

[0027] The method and system for the non-destru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com