Process for making curved glass touch panel

A manufacturing process, touch panel technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc. Accuracy and touch performance, improved hardness and wear resistance, the effect of meeting arc requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described below in conjunction with accompanying drawing.

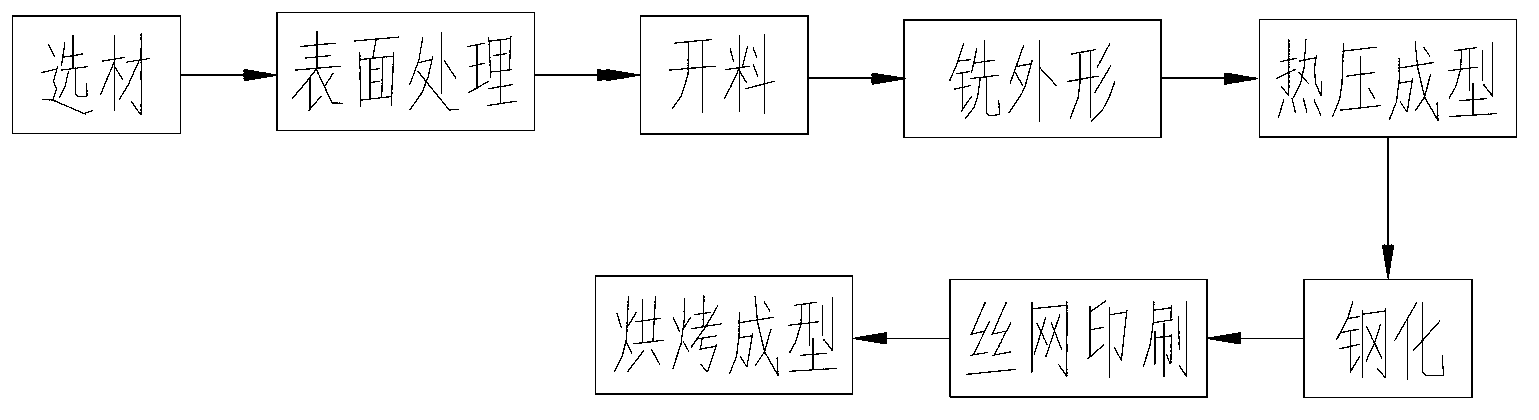

[0018] as attached figure 1 Shown is a manufacturing process of a curved glass touch panel according to the present invention, which mainly includes the following steps:

[0019] (1) Material selection: select raw material glass A with a thickness of 1.7mm;

[0020] (2) Surface treatment: The raw material glass A is subjected to sandblasting treatment by surface sandblasting process, and the roughness is controlled to 0.2 to obtain glass B;

[0021] (3) Cutting: cut the glass B into multiple square glasses C with the desired appearance size, the size of the square glass C in this embodiment is 121*119mm;

[0022] (4) Milling shape: milling the four corners of the square glass C to be rounded and chamfered to make glass D;

[0023] (5) Hot press molding: hot press glass D into a 360-degree arc surface, the angle of the arc surface is controlled at ±2 degrees, and the height tolerance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com