Nondestructive Fault Injection Method Supported by Airborne Redundancy Computer for Fault Tolerant Verification

A fault injection, computer technology, applied in the direction of calculation, error detection/correction, instrument, etc., can solve the problems of reducing the basic reliability of the product, destroying the real-time effective data, increasing the calculated value of the number of failures, etc., to achieve a concise design scheme structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

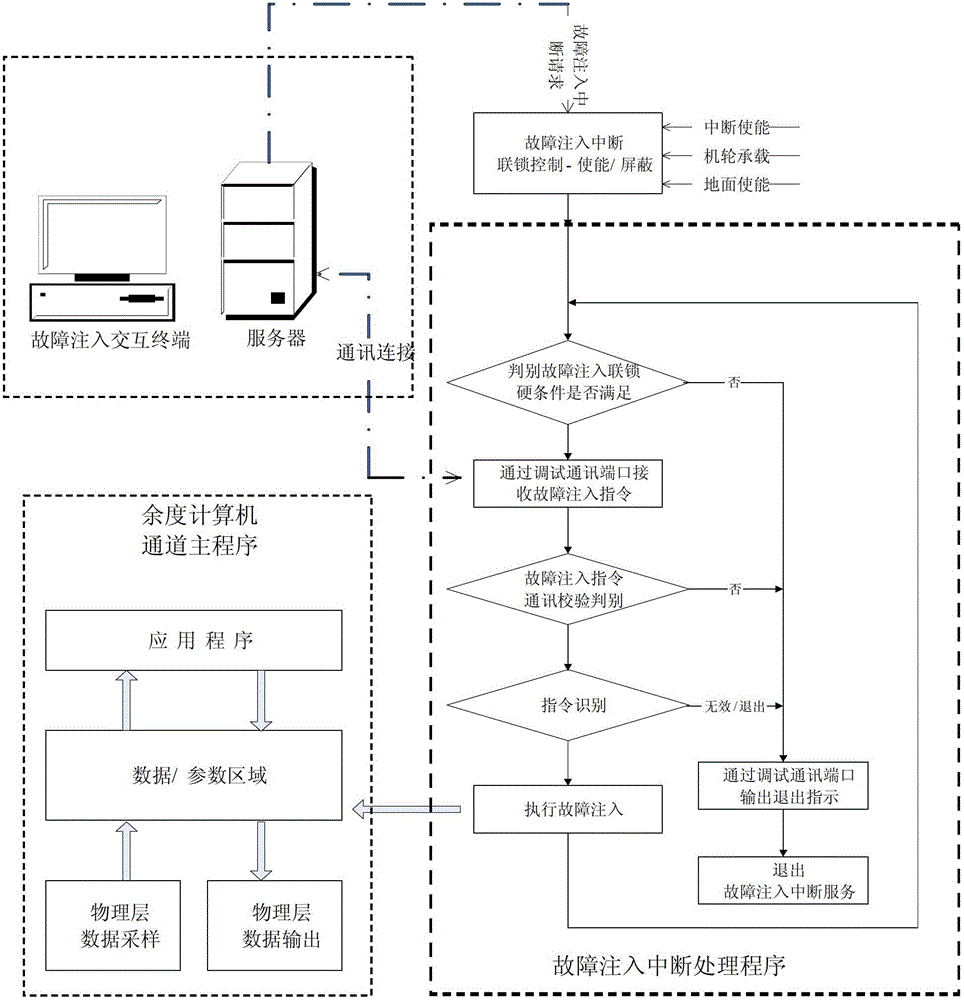

[0017] The technical scheme of the present invention is composed of 4 parts as shown in the figure: the main program of the redundant computer channel is the target object to be implemented by fault injection, and the fault injection interrupt service program with a safety mechanism is to reside in the redundant computer channel to perform fault injection Embedded software tool, fault injection interactive terminal for editing fault content, and server for sending fault injection instructions and interrupt requests constitute a fault injection simulation environment, and fault injection interrupt interlocking control.

[0018] This scheme mainly adopts the double protection strategy combining software and hardware design to ensure that the fault injection interrupt execution program can run safely and reliably. In terms of hardware, in order to prevent false triggering of interrupt requests, the "enable / shield" mechanism is used in the redundant computer channel to control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com