Forecasting method of baking sheet smoke

A prediction method and flue gas technology, applied in prediction, data processing application, calculation, etc., can solve the problems of time-consuming and laborious detection process and high detection cost, and achieve the effect of ensuring robustness and good estimation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is based on the robust regression modeling method for predicting the flue gas of grilled slices or the system client runs on the Windows platform, and the server adopts the SQL SERVER database system.

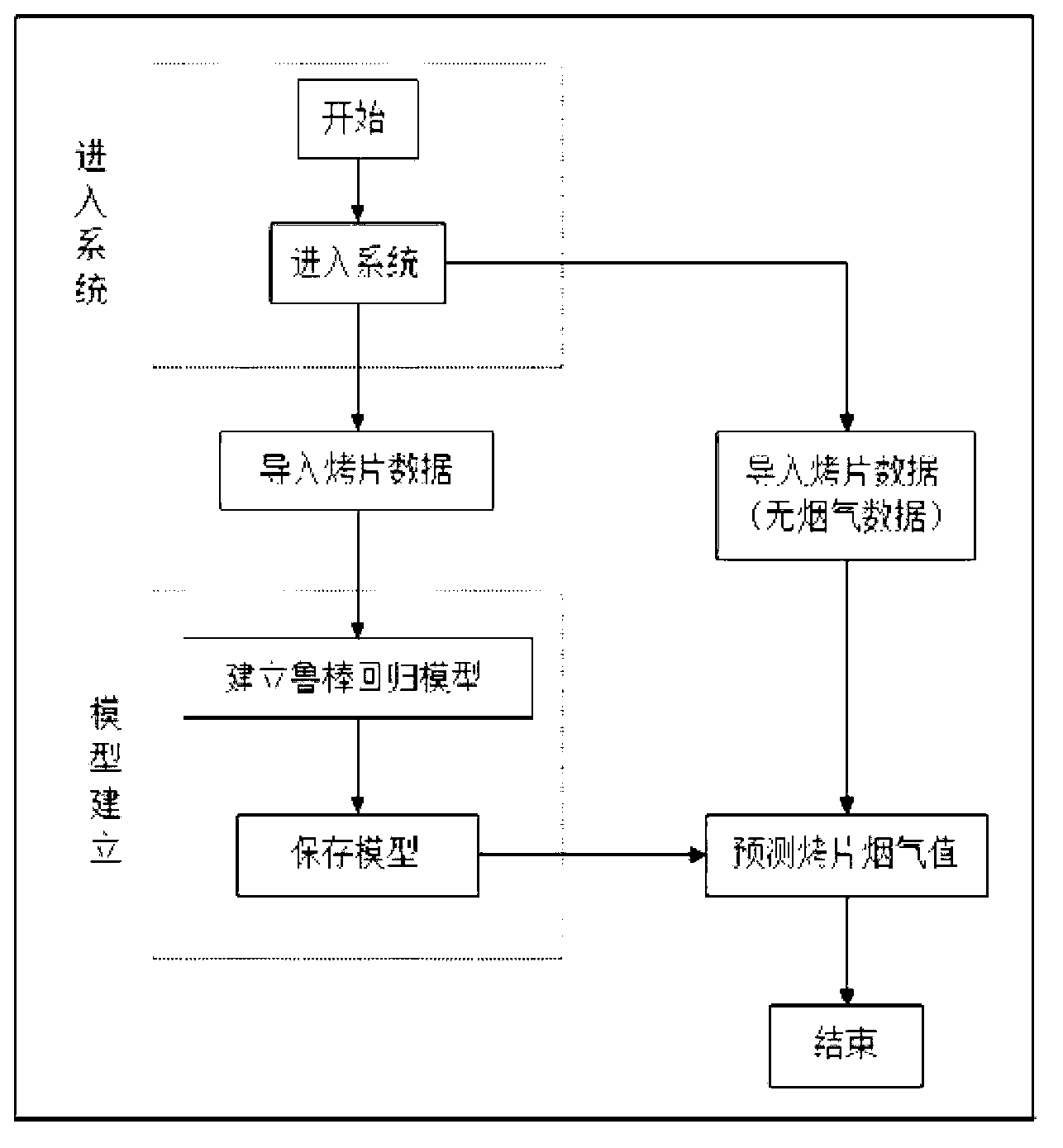

[0030] The smoke prediction system based on robust regression modeling of the present invention mainly includes two major contents:

[0031] Content 1: Modeling based on the known smoke data of the grill;

[0032] Content 2: Use a robust regression model to predict the smoke value of unknown roasted slices;

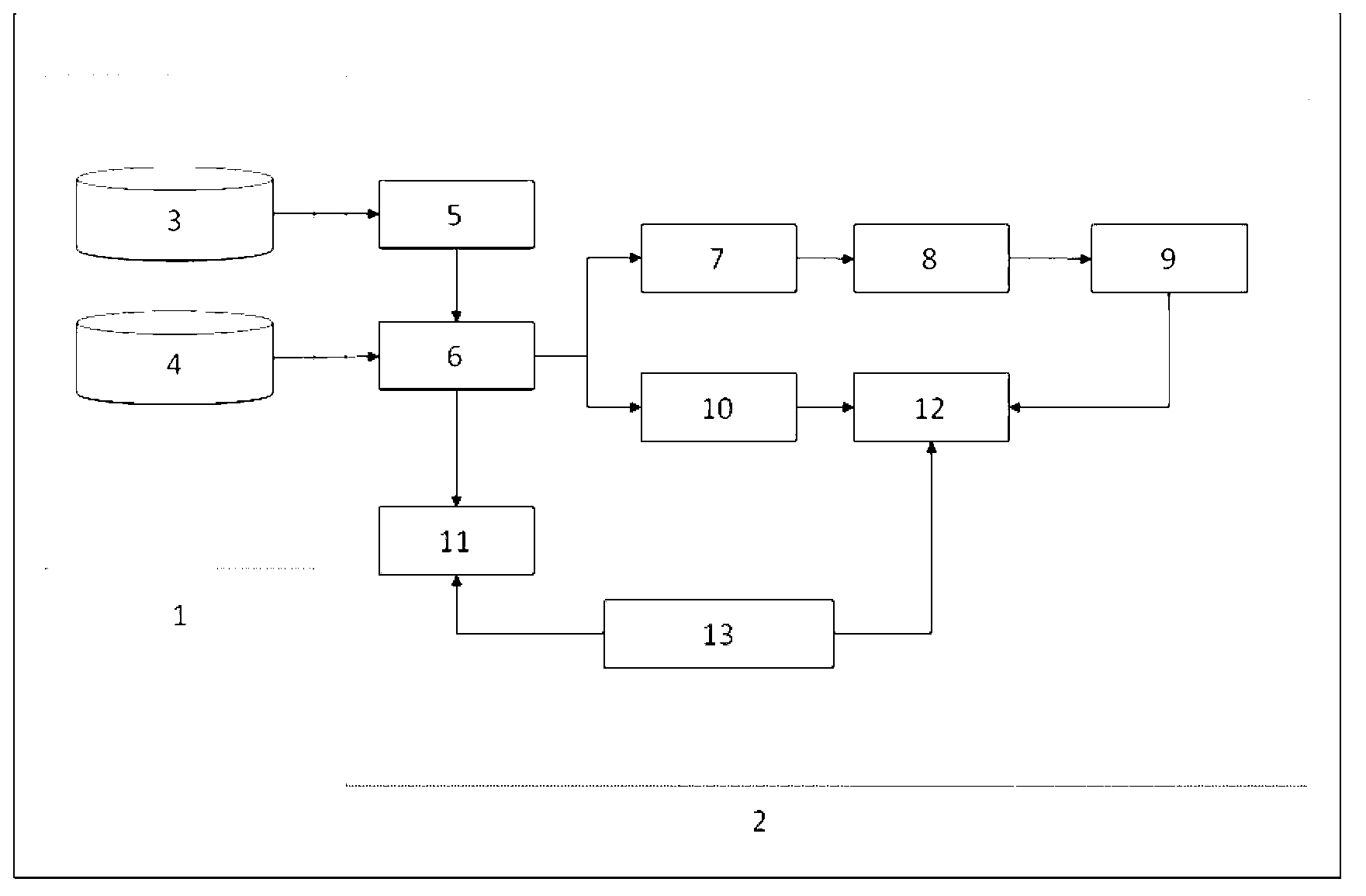

[0033] First, the present invention constructs a modeling system based on C / S mode, which mainly includes a database server and a model client. The client provides a user interface interaction window to accept user input information, provide an interactive interface for the modeling process, and display model prediction results. It is characterized by the following modules, and its system structure diagram is shown in the appendix figure 1 : ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com