Default phase fault tolerance driving system of open winding motor

A drive system and open winding technology, applied in control systems, control generators, vector control systems, etc., can solve problems such as torque ripple, zero-sequence current, and reconstruction of the remaining two-phase current, and achieve an increase in output power level , maintaining torque output and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described below with reference to the accompanying drawings.

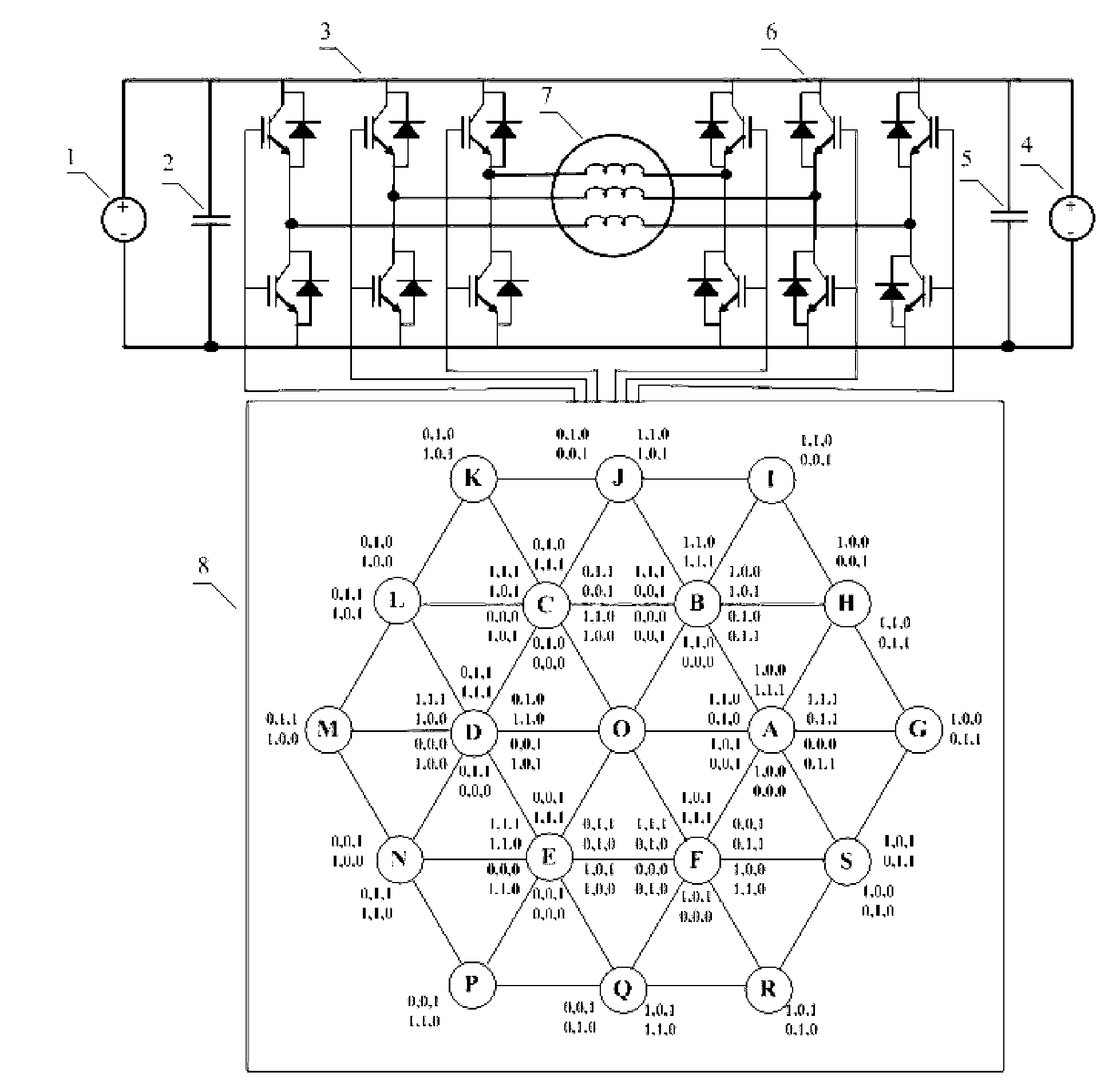

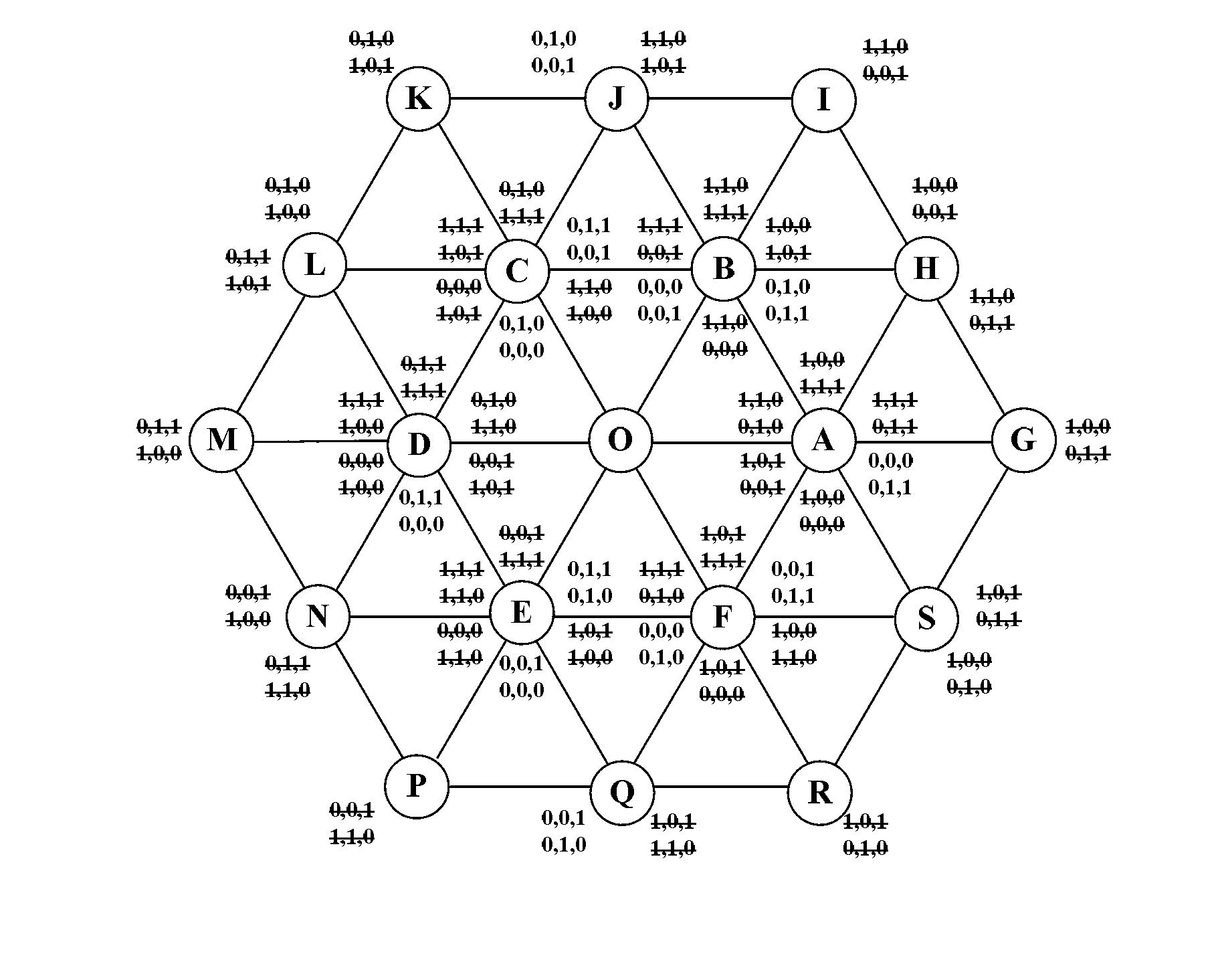

[0025] The invention provides a new open-winding motor open-circuit fault-tolerant drive system, which separates the neutral points of the three-phase motor windings, and cascades two nominal two-level inverters at the head and end. , the two switches of the upper bridge arm of the faulty phase are blocked online, and the two switches of the lower bridge arm are always "1" driven, and the inherent redundant switch vector of the cascaded inverter is reconstructed, and then the fault-tolerant redundant switch vector is spaced Vector modulation, which reconstructs the remaining two-phase currents in a vector-controlled three-phase motor drive system. The device includes a primary DC voltage source 1 , a primary capacitor 2 , a primary inverter 3 , a secondary DC voltage source 4 , a secondary capacitor 5 , a secondary inverter 6 , a three-phase motor 7 , and a redundant switch vect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com