Advanced phase compensation control unit and method for double-CPU (central processing unit) intelligent wound-rotor motor

A compensation controller, winding technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of low reliability, low stability, burning components, etc., to achieve high reliability and high stability , the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is a detailed description of an intelligent winding motor phase advance compensation controller and control method with a dual-CPU structure provided by the present invention in conjunction with specific embodiments:

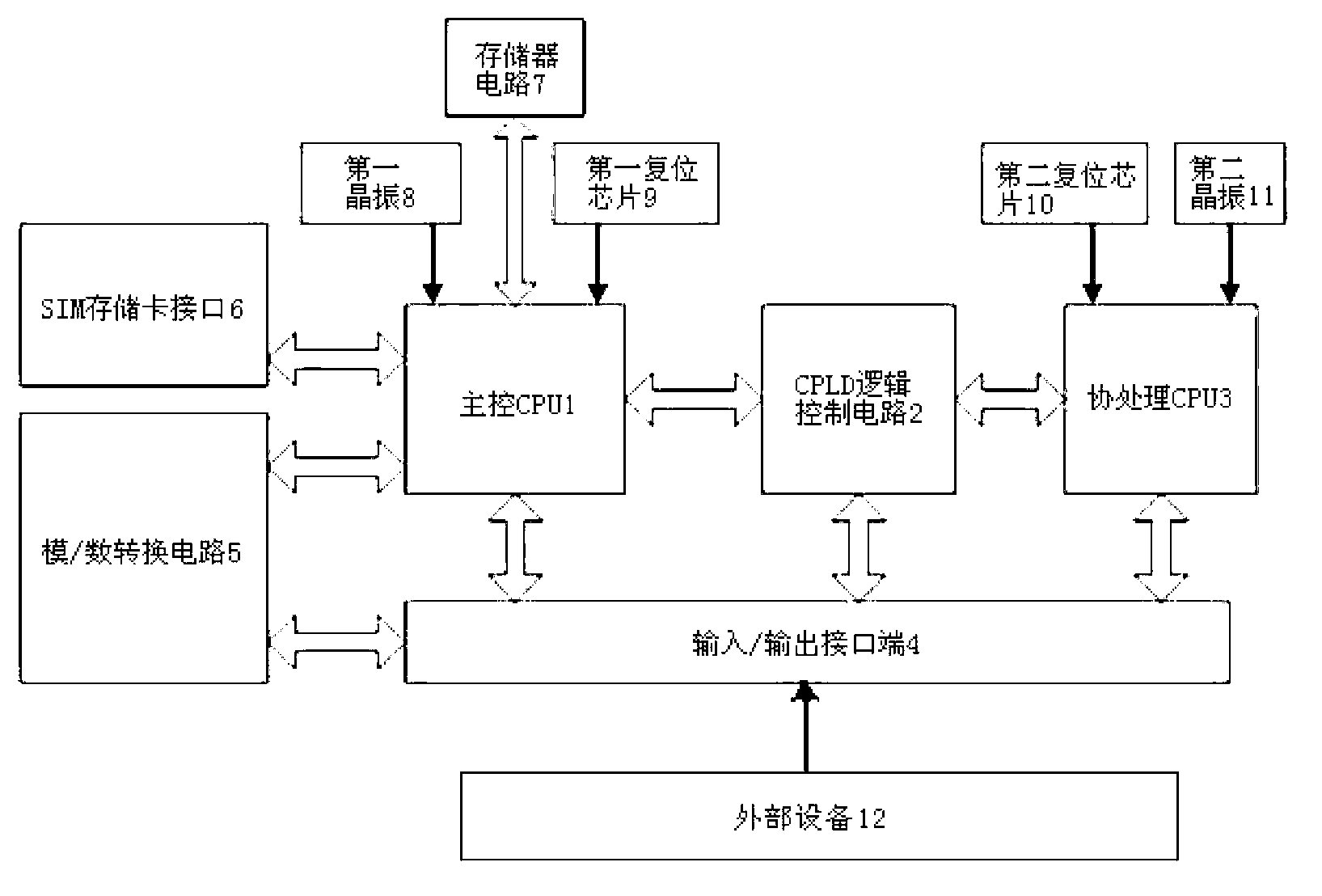

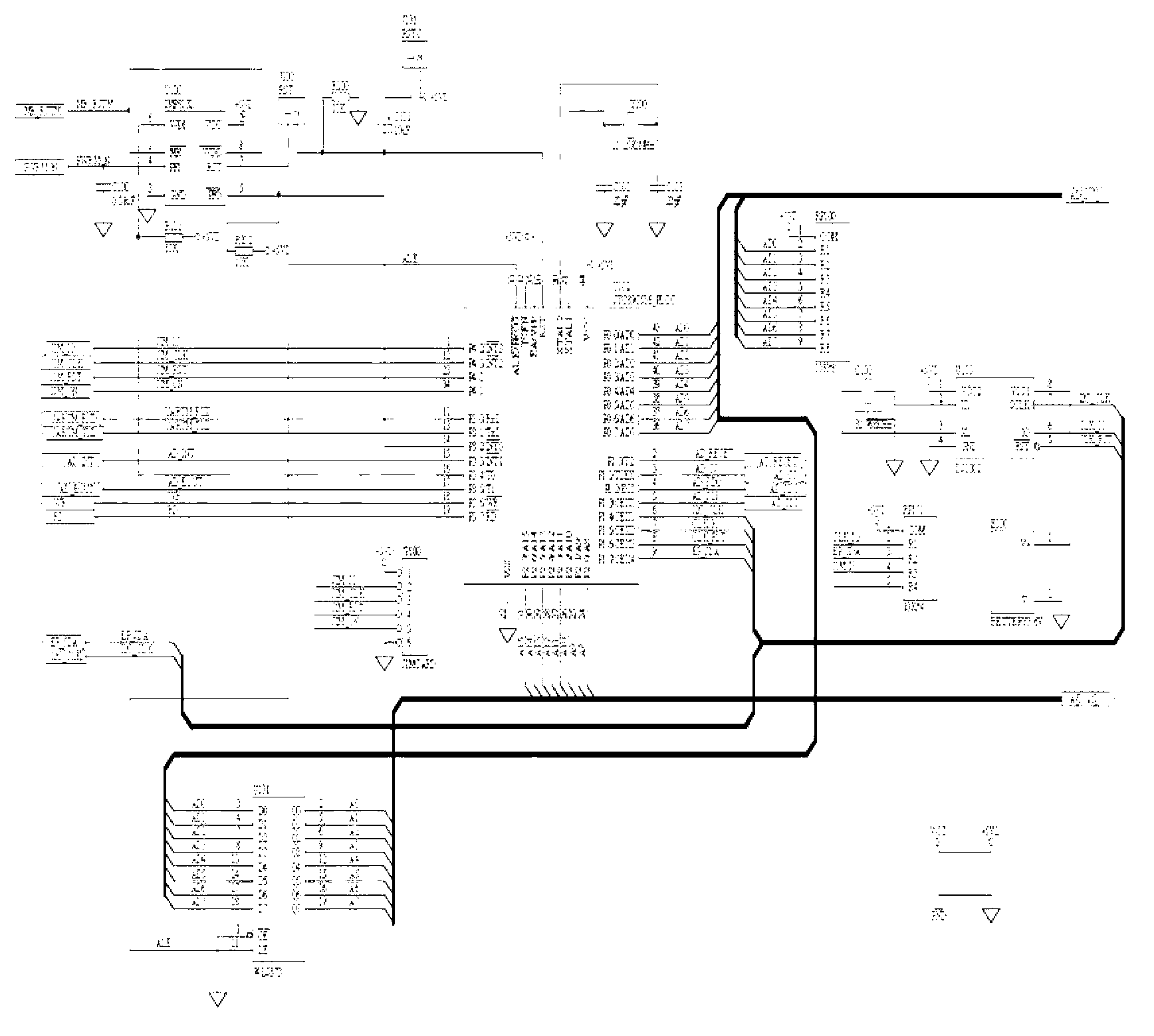

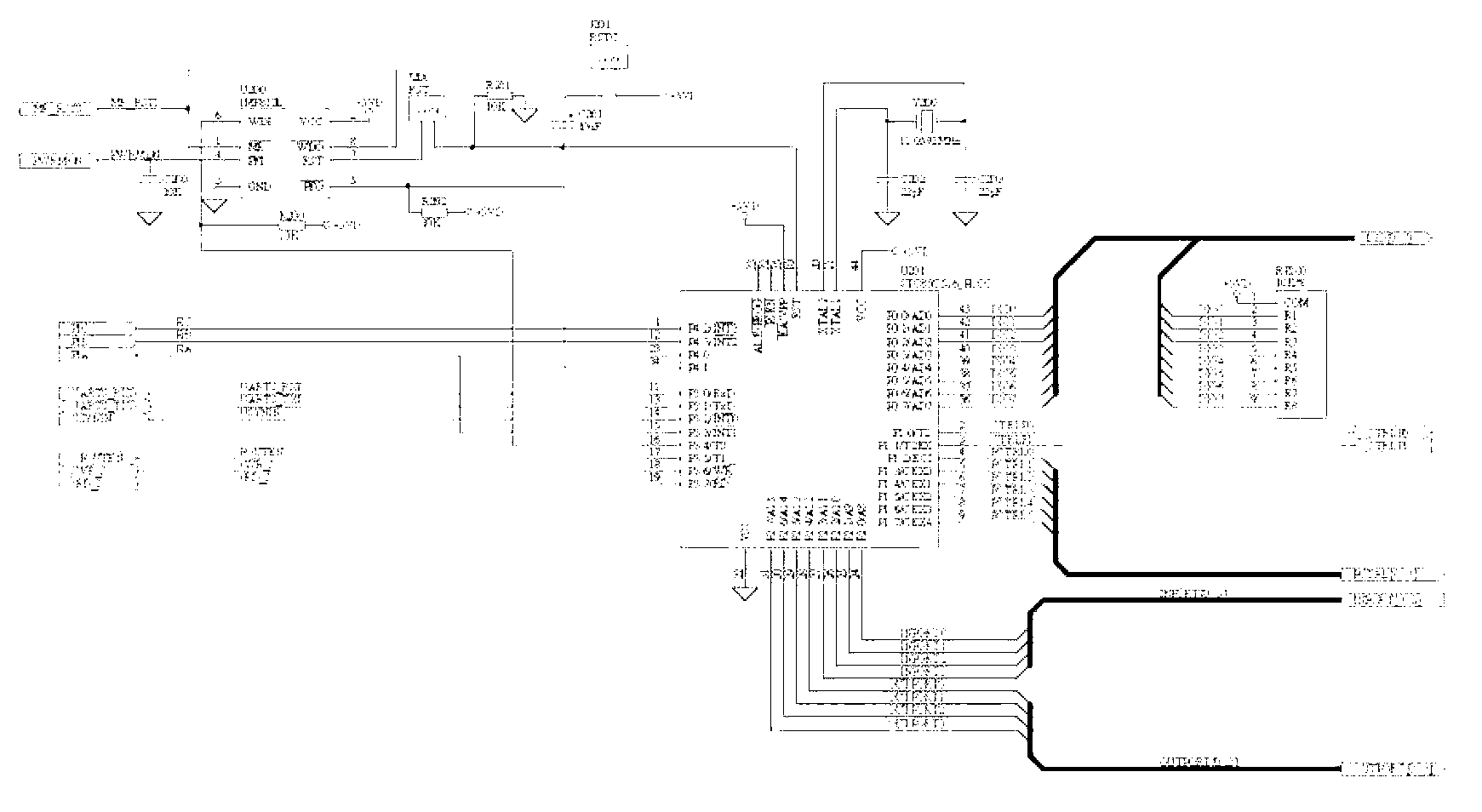

[0034] Such as figure 1 As shown, the intelligent winding motor phase advance compensation controller with dual CPU structure includes main control CPU1, CPLD logic control circuit 2, co-processing CPU3, input / output interface terminal 4, analog / digital conversion circuit 5, SIM memory card Interface 6, memory circuit 7, first crystal oscillator 8, first reset chip 9, second reset chip 10, second crystal oscillator 11 and external device 12; CPLD logic control circuit 2, input / output interface port 4, analog / digital conversion Circuit 5, SIM memory card interface 6, memory circuit 7, first crystal oscillator 8 and first reset chip 9 are all connected with main control CPU1; Analog / digital conversion circuit 5 is connected with input / output i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com