Method for optimization selection of water treatment filter material

A water treatment and filter material technology, applied in the direction of separation methods, chemical instruments and methods, loose filter material filters, etc., to achieve reliable performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

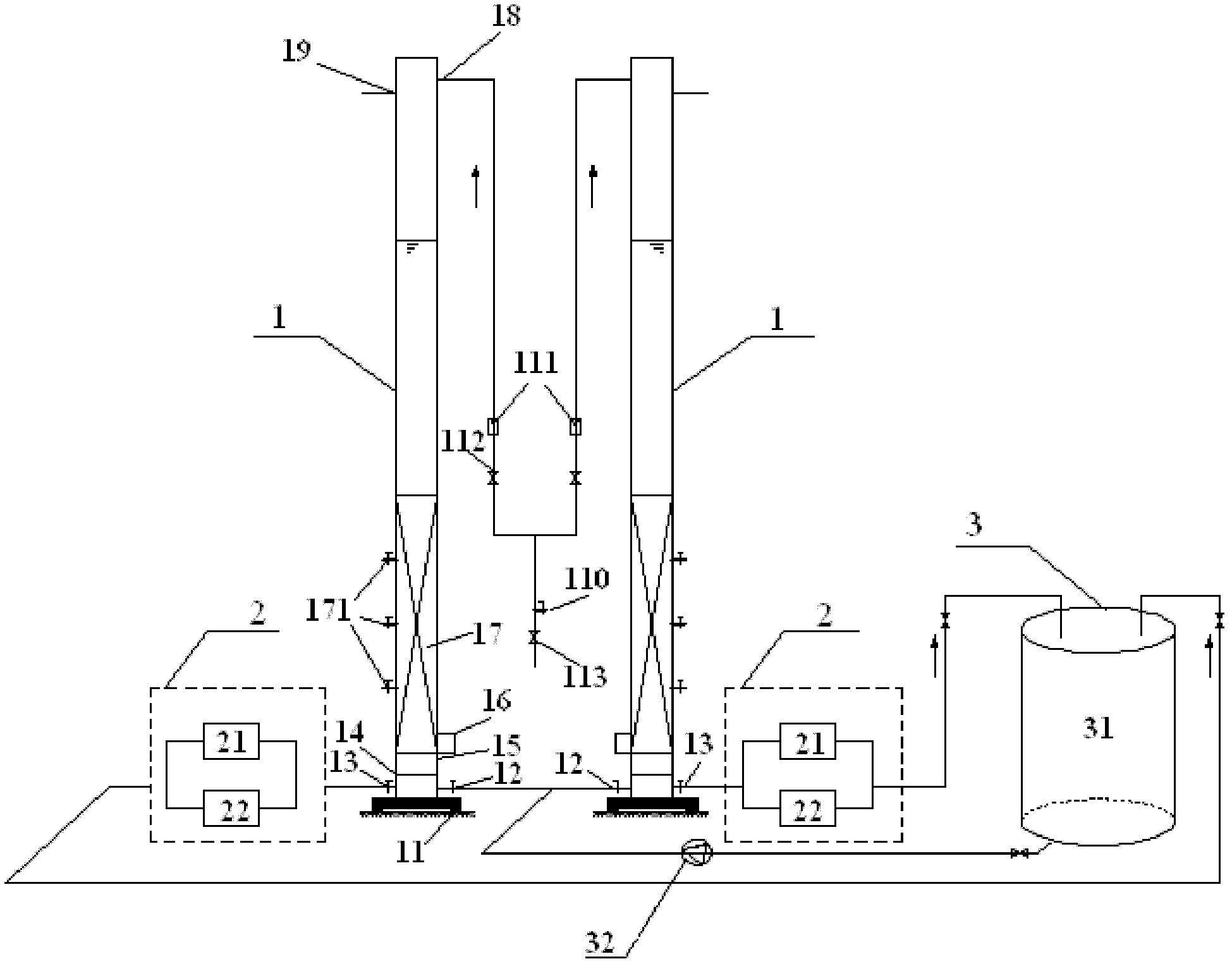

[0025] The water treatment of this embodiment is preferably a filter device, such as figure 1 As shown, it includes two filter columns 1 connected in parallel, a real-time water quality monitor 2 matched with each filter column, and a filter column backwasher 3 matched with each filter column.

[0026] The bottom of the filter column 1 is provided with a base 11, the top side wall of the filter column is provided with a water inlet 18 and an overflow port 19 sequentially from top to bottom, and the bottom side wall of the filter column is provided with a total water outlet 13 and backwashing port 12. The filter column is provided with a filter plate 14, a coarse sand supporting layer 15 and a filter material layer 17 from bottom to top. The side wall of the filter column with the filter material layer is from top to bottom A plurality of sampling tubes 171 are provided, and the bottom end of the side wall of the filter column with the filter material layer is provided with a sand...

Embodiment 2

[0041] The process of filtering material optimization:

[0042] Using the device for water treatment of preferred filter material of Example 1 and the method of water treatment of preferred filter material of Example 1 to optimize 1# and 2# filter media.

[0043] In order to investigate the difference in the filtration performance of the two filter media, compare the filtration effects of the two filter media under the same working conditions. 1# is fine sand with a particle size of 0.7~0.9mm, and 2# is coarse sand with a particle size of 0.9 ~ 1.1mm. The inlet water of the filter column is the effluent from a coagulation sedimentation tank of a water plant. The turbidity of the inlet water is 1.0-2.0 NTU, and the number of particles larger than 2 μm in the inlet water is 4000-8000 / mL. The filtration speed of the two filter columns is the same, ranging from 8 to 12m / h. The total number of particles in and out of the water, particle size distribution and turbidity of the two filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com