Welding device and method based on binocular vision sensing of structured light

A binocular vision and welding device technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as serious health threats, difficult level adjustment, cumbersome operation, etc., achieve accurate identification, improve image processing speed, and improve The effect of positioning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to illustrate the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

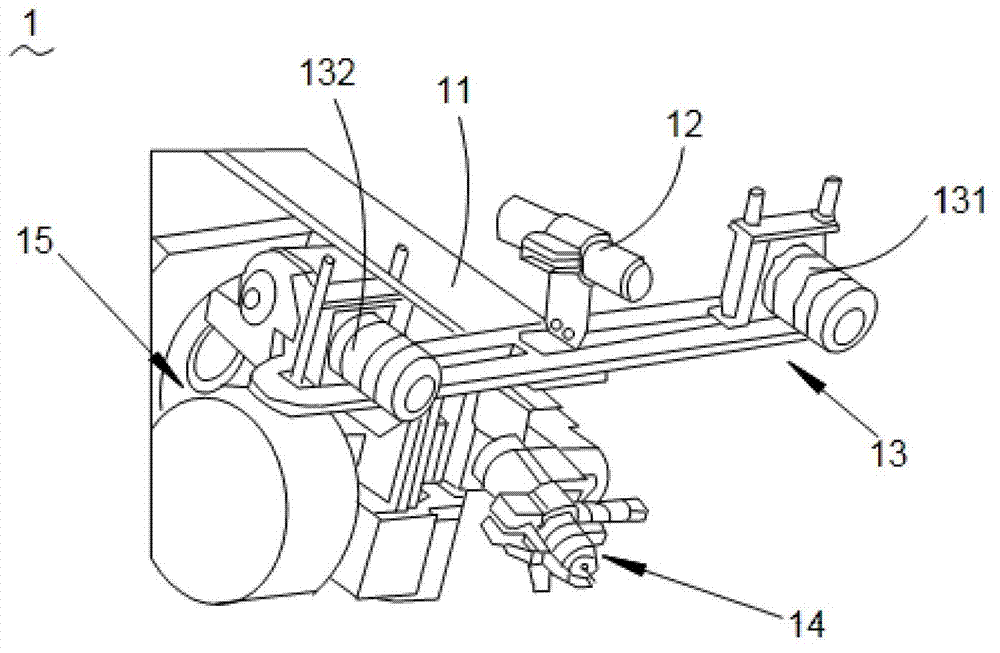

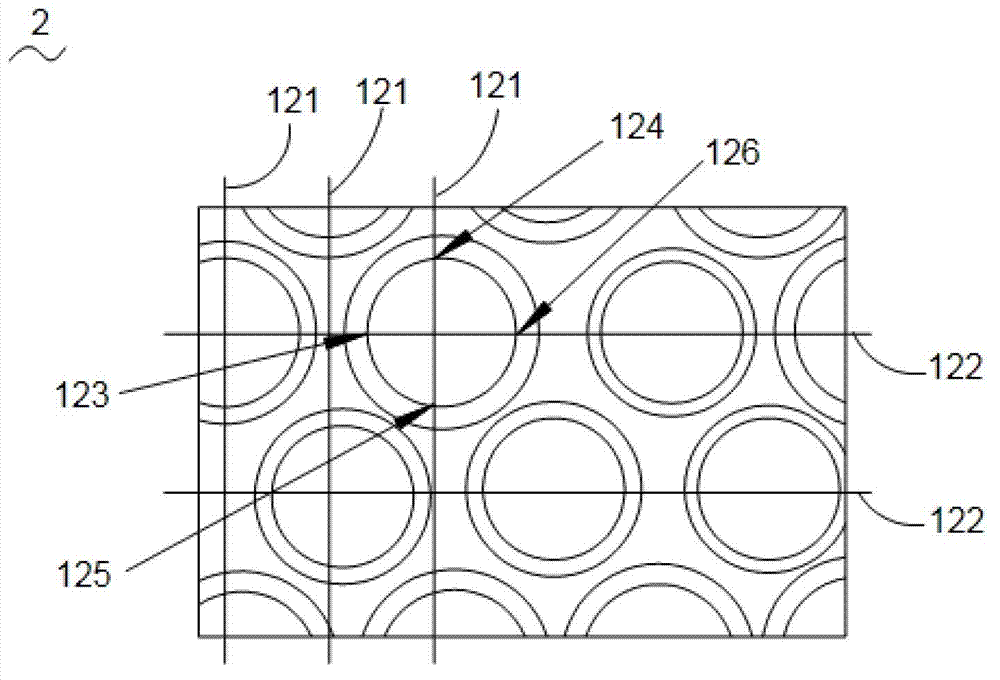

[0019] see figure 1 , and see in conjunction with figure 2 , figure 1 Shown is a structural schematic diagram of the welding device based on structured light binocular vision sensing of the present invention. figure 2 Shown is a schematic diagram of the positioning principle of the tube sheet pattern to be welded by the welding device based on the structured light binocular vision sensor of the present invention. The welding device 1 based on structured light binocular vision sensing includes a mounting bracket 11, and the mounting bracket 11 is used to install the welding device 1 based on structured light binocular vision sensing; a structured light emitter 12, the The structured light emitter 12 is a laser emitter, which is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com