Light-weight six-shaft universal robot

A robot and six-axis technology, applied in the field of robotics, can solve the problems of increased difficulty in installing protective devices, high robot production costs, and large structural volume, and achieve compact space for the front and rear arms, reduce the use of empty space, and simplify the machine structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

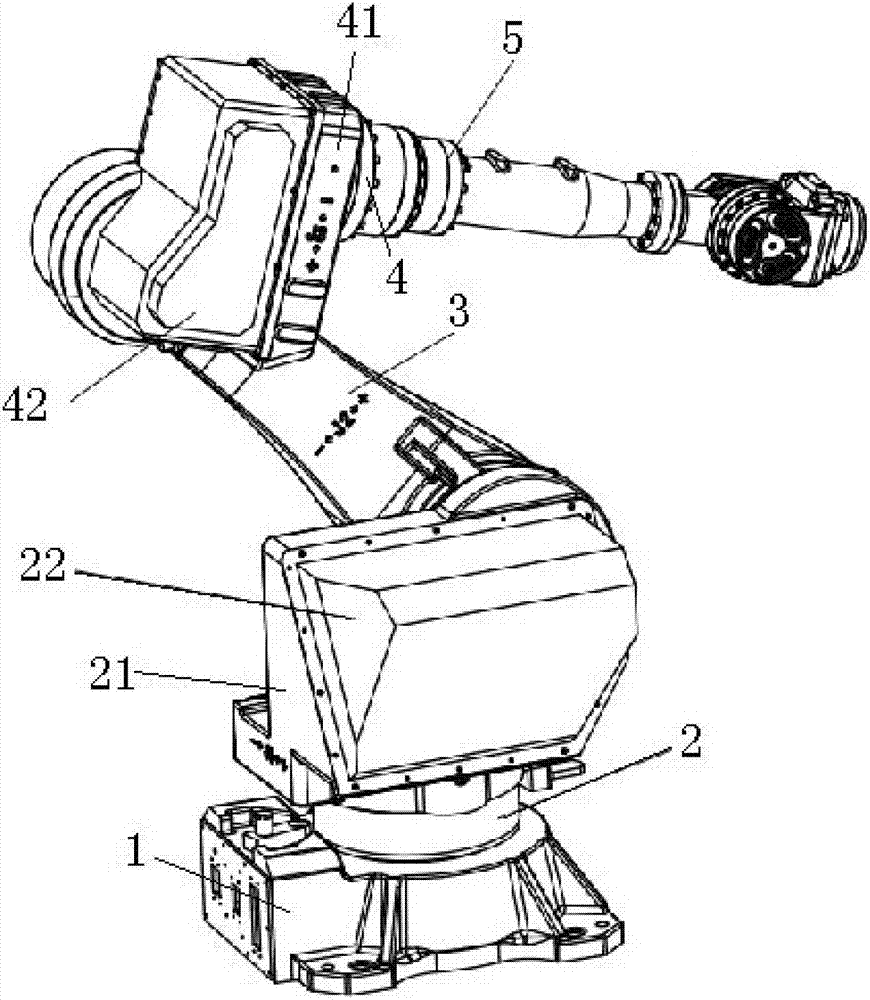

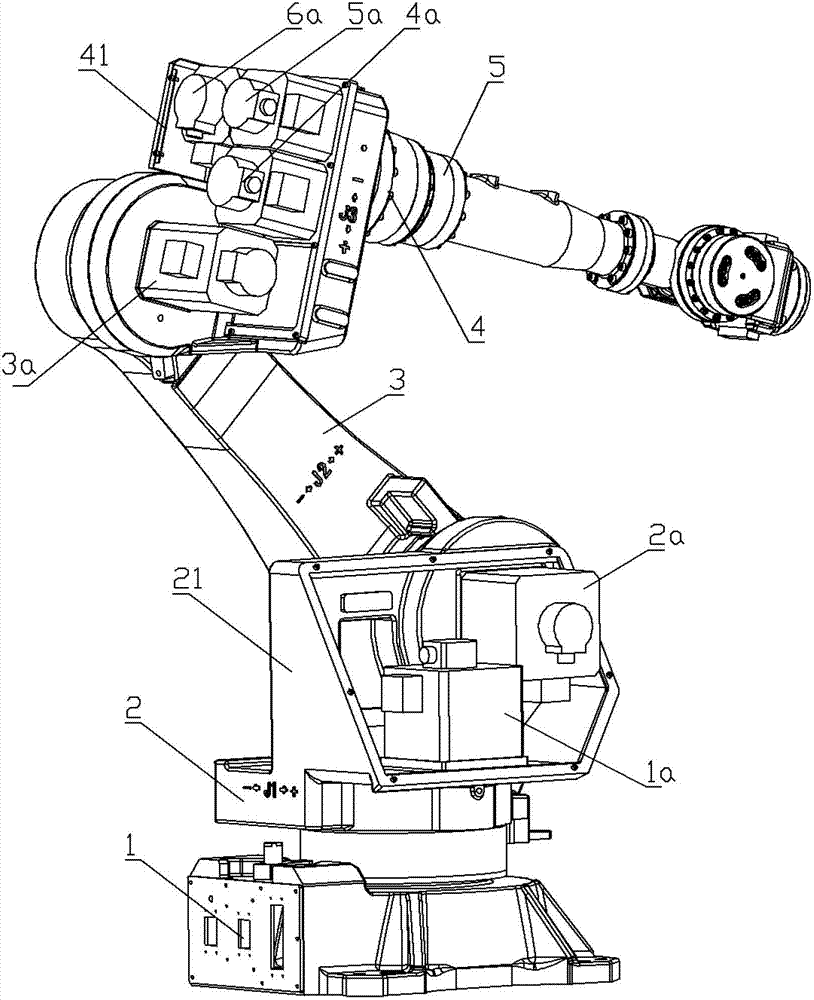

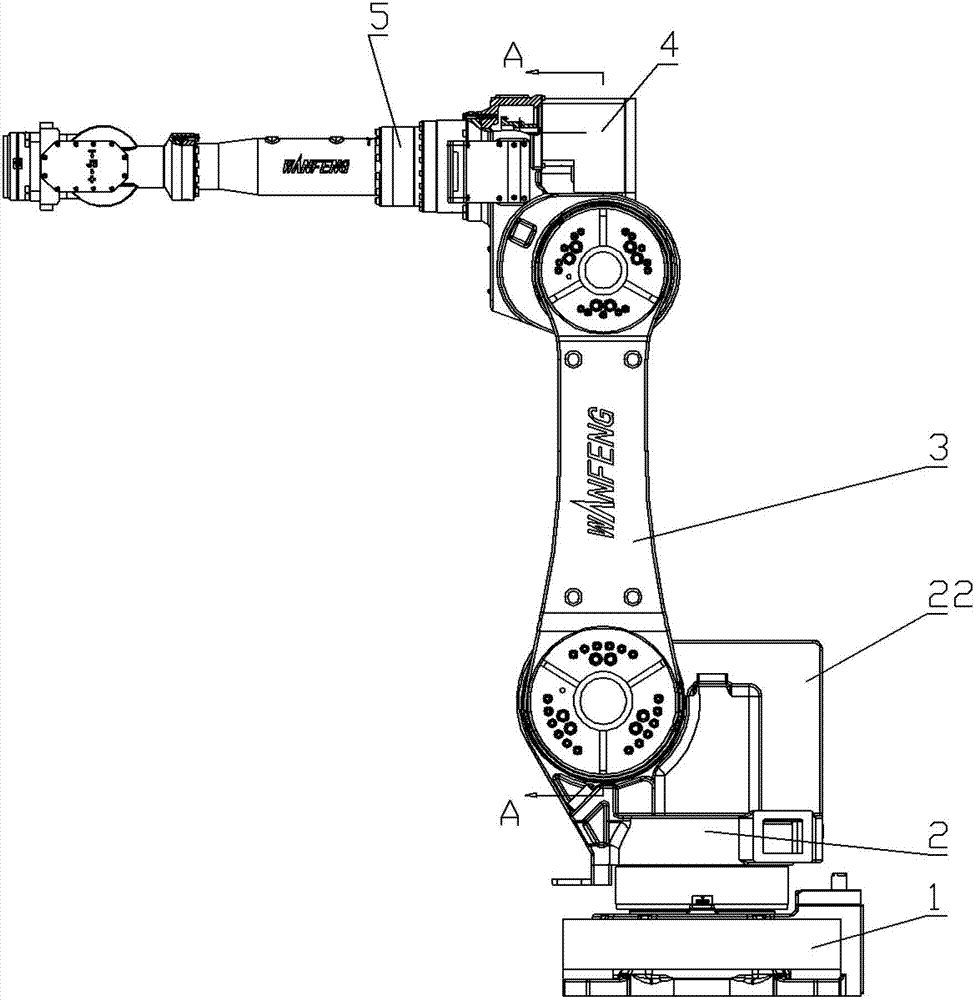

[0020] Example: see Figures 1 to 5 As shown, a light-duty six-axis universal robot includes a base 1, a waist rotating part 2, a large arm 3, an axle seat 4, and a small arm 5. The waist rotating part 2 rotates around the base 1, and the big arm 3 rotates around the waist rotating part 2. A waist rotation protection box 21 is formed on the rotation part 2, and the first shaft drive motor 1a and the second shaft drive motor 2a are fixed in the waist rotation protection box 21, and the waist rotation protection box 21 is fixedly connected with a waist rotation box cover 22 by screws , a sealing gasket is installed between the waist-turning box cover 22 and the waist-turning protection box 21;

[0021] The rotating shaft of the second shaft drive motor 2a is fixedly connected to the input shaft of the boom gear reducer 31, and the output shaft of the boom gear reducer 31 is fixed on the boom 3;

[0022] A shaft seat protection box 41 is fixed on the shaft seat 4, and the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com