Full-automatic multifunctional packaging machine

A multi-functional, packaging machine technology, applied in multiple packaging, packaging, transportation packaging and other directions, can solve problems such as changing the mechanical appearance of food packaging, and achieve the effects of improving thermal sterilization efficiency, facilitating maintenance, and accelerating heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

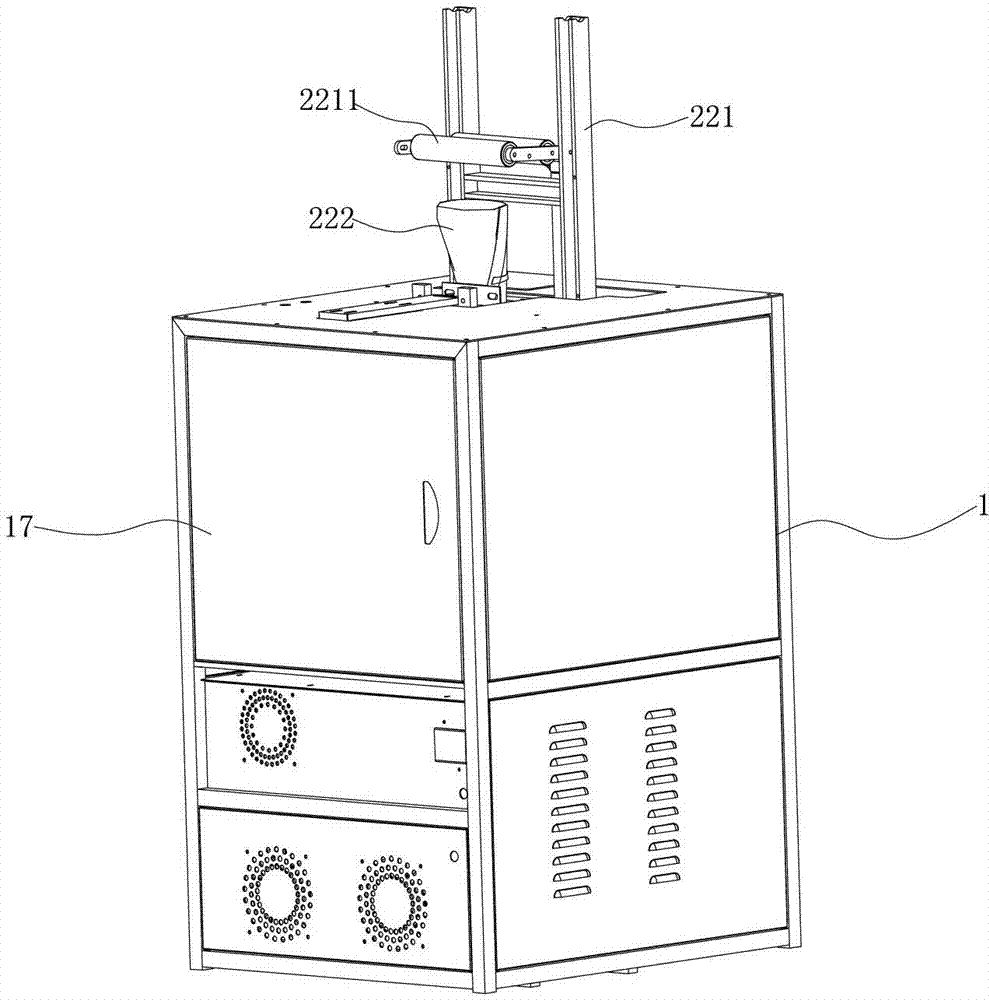

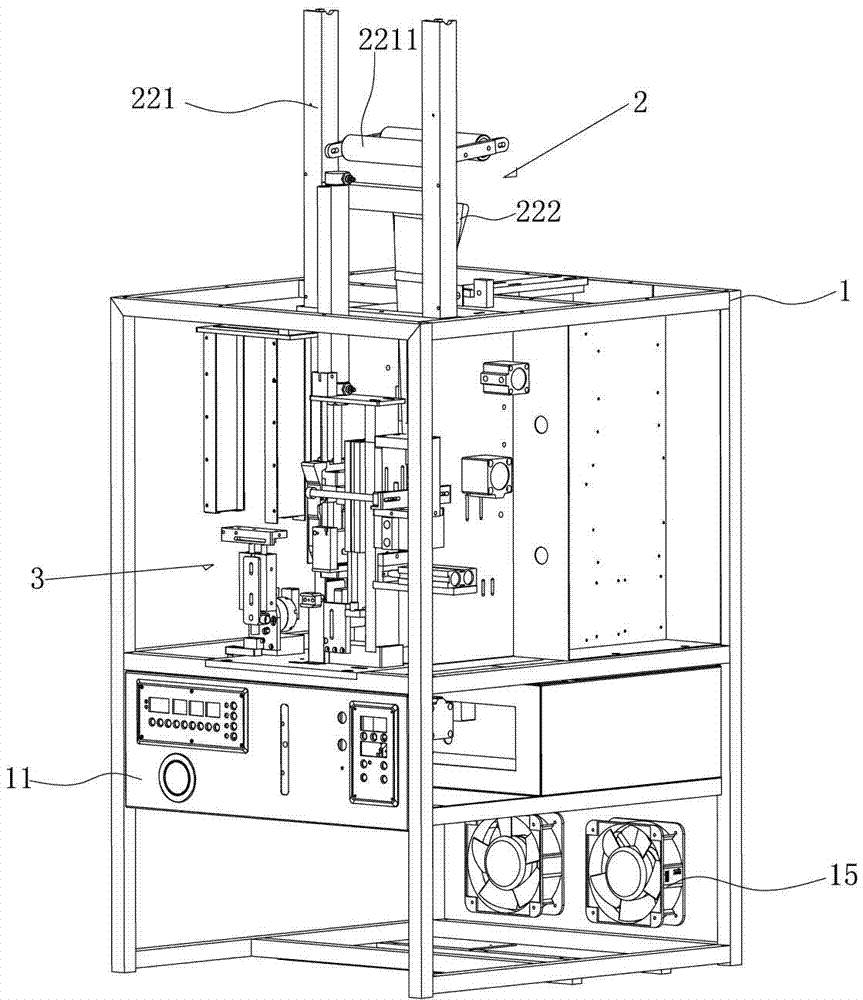

[0062] See Figure 1-11 As shown, the fully automatic multifunctional packaging machine includes: frame 1, inner film sealing structure 2, blanking mechanical structure 3 and small warehouse structure 4, frame 1 is used as the support of the entire packaging machine, and frame 1 is provided with The driving circuit and the control panel 11 for controlling the operation of the packaging machine, the inner film tuyere structure 2, the blanking mechanical mechanism 3 and the small warehouse structure 4 are installed in the frame 1 from top to bottom, the inner film sealing structure 2, the blanking mechanical structure 3 Photoelectric sensors are all installed in the small warehouse structure 4 . in:

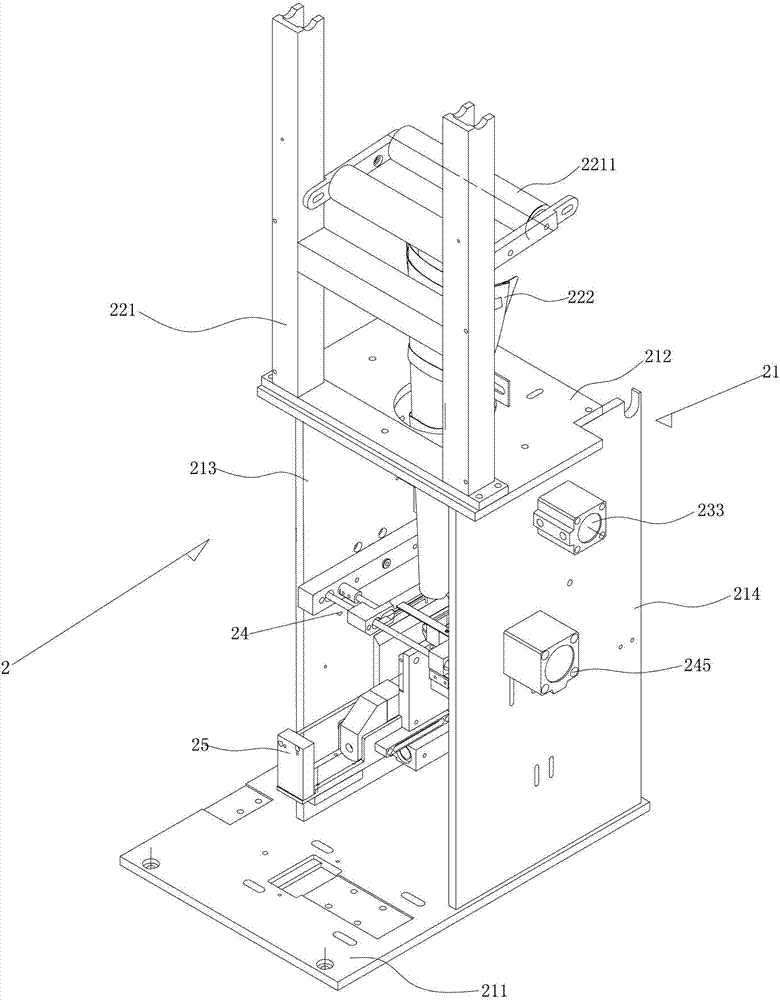

[0063] The intima sealing structure 2 includes: a support frame 21, a feeding mechanism 22, a longitudinal sealing mechanism 23, a transverse sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com