Degradable material for surgical knife handle and its manufacturing method

A technique of surgical knife handle and manufacturing method, which is applied in the direction of anatomical instruments, etc., to achieve the effect of good clinical practical value, detailed and reasonable preparation process, and reasonable compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

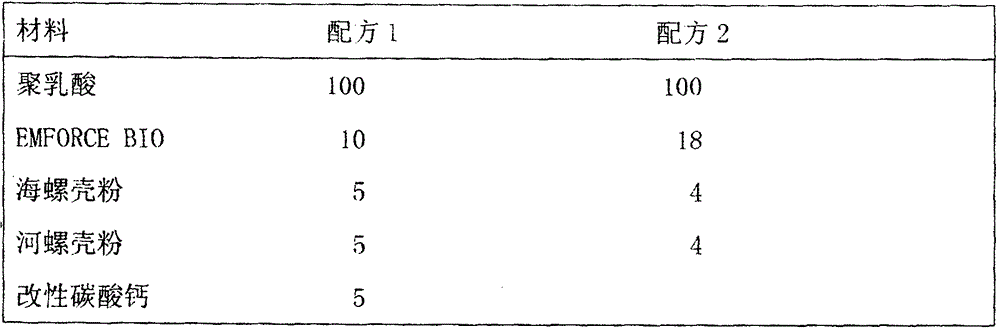

Embodiment 1

[0026] The injection molding method of embodiment 1 degradable scalpel handle:

[0027] The first step, vacuum drying: dry the degradable substrate pellets of formula 1 or formula 2 at 50°C for 3 hours in vacuum, and set aside;

[0028] The second step, injection molding: add the dried degradable substrate pellets of formula 1 or formula 2 to an injection molding machine for injection molding.

[0029] The barrel temperature is set as follows: feed inlet 160°C, compression section 165°C, metering section 175°C, nozzle 170°C;

[0030] Mold temperature: 15-20°C;

[0031] The injection pressure is: the first section is 75pa, the second section is 80Mpa, and the third section is 50Mpa;

[0032] Injection molding cycle: 43 seconds;

[0033] The holding time is: 0 seconds;

[0034] The screw speed is: 180 rpm.

[0035] Obtain the degradable scalpel handle adopting the degradable base material of formula 1 or formula 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com