Wood veneer skeleton accessory installation structure

A wood veneer and installation structure technology, which is applied in building construction, covering/lining, construction, etc., can solve the problems of time-consuming installation of wood veneer, easy to be deformed by moisture, pollution, etc., to ensure the quality of decoration, improve construction efficiency, The effect of easy disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

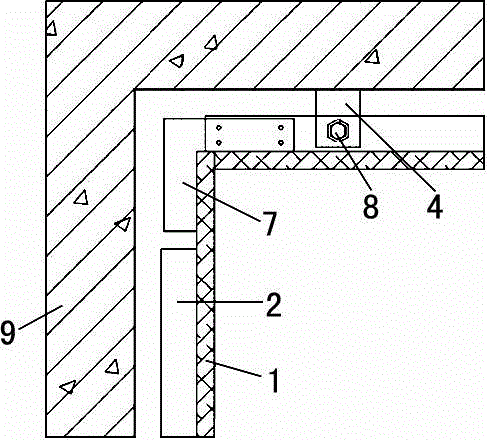

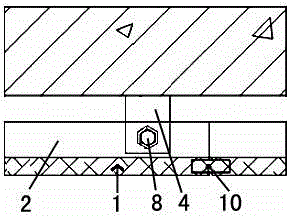

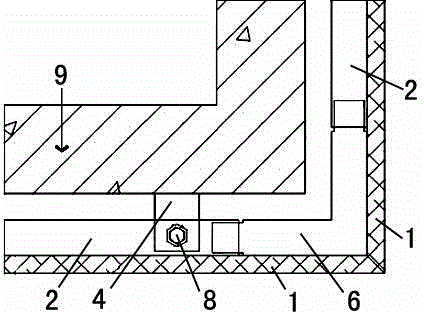

[0028] Example: such as Figure 1 to Figure 7 As shown, a wooden veneer skeleton accessory installation structure, which includes a wooden veneer 1, a square tube 2, a corner code 4, an L-shaped square tube connector 6, and an L-shaped positioning piece 7.

[0029] A square tube 2 is arranged on the back of the wooden veneer 1, and the corner code 4 is fixed to the building wall 9 by expansion bolts, and the square tube 2 and the corner code 4 are fixed by the through-hole bolt 8; A wood veneer 1 is handed over to form the male corner, one end of the L-shaped square tube connector 6 is plugged into the square tube behind a piece of wood veneer 1 in the male corner, and the other end of the L-shaped square tube connector 6 is connected to the male corner. The square tube behind another piece of wood veneer 1 in the corner is plugged in; at the inner corner of the wall, one piece of wood veneer 1 is handed over to another wood veneer 1 to form an inner corner, and one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com