Starter

A technology of starter and sliding bearing, which is applied in the direction of engine components, engine starting, machine/engine, etc., can solve the problem of reducing the life of the starter, and achieve the effect of improving the life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

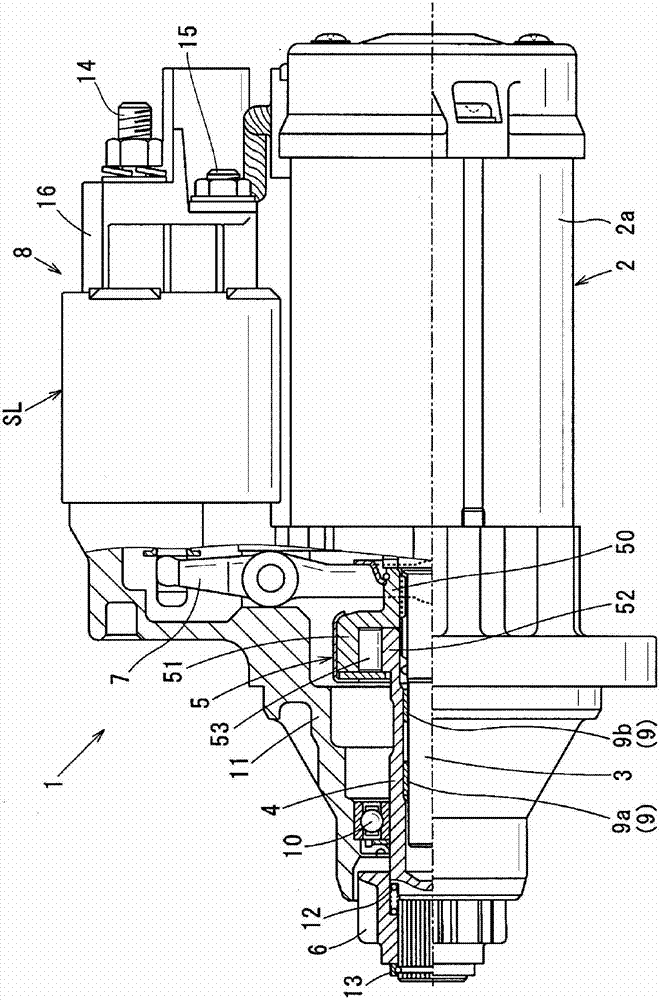

[0034] figure 1 A starter 1 according to a first embodiment is shown. Such as figure 1 As shown, the starter 1 includes a motor 2 , an output shaft 3 , a pinion tube 4 , a clutch 5 , a pinion 6 and an electromagnetic switch 8 . The motor 2 receives supplied electric power to generate torque. The output shaft 3 is driven to rotate by the motor 2 . The pinion tube 4 is fitted on the outer periphery of the output shaft 3 with a spline connection. The clutch 5 transmits the rotation of the output shaft 3 to the pinion tube 4 . The pinion 6 is supported at the end on the anti-motor side in the axial direction of the pinion tube 4 . The electromagnetic switch 8 has a function of driving the shift lever 7 by the attractive force of the electromagnet so that the pinion tube 4 faces the anti-motor side in the axial direction with the clutch 5 with respect to the output shaft 3 ( figure 1to the left of the ) shift. In addition, the electromagnetic switch 8 opens and closes mai...

no. 2 approach

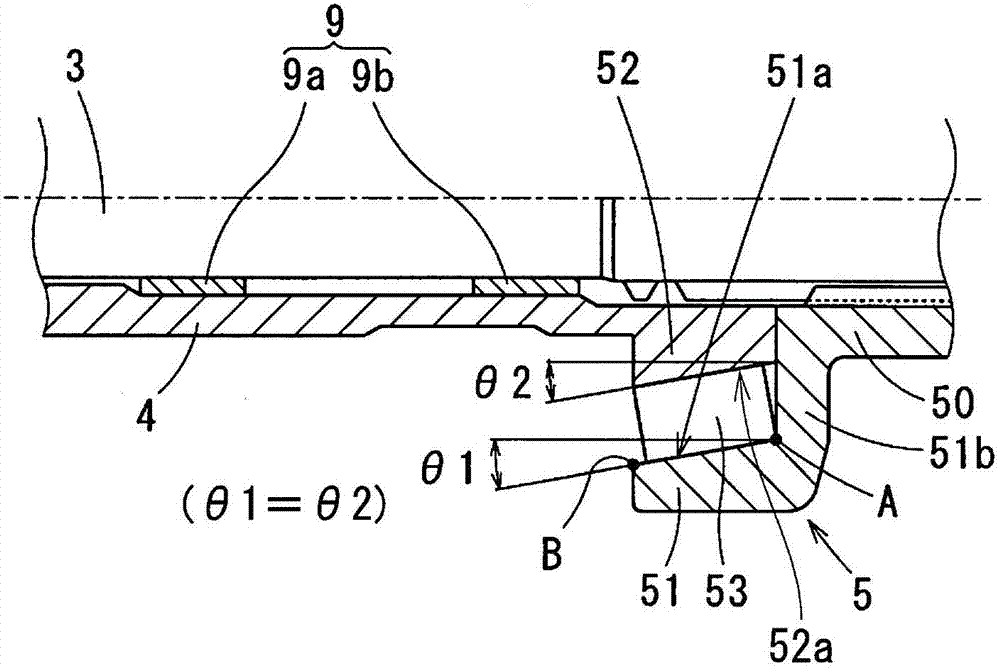

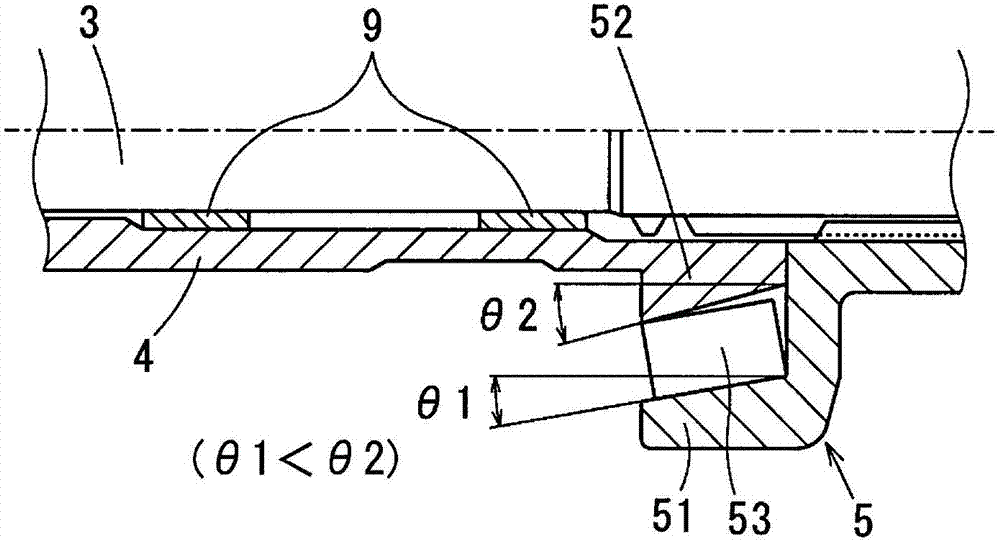

[0058] In the first embodiment, if figure 2 As shown, the taper angle θ1 of the inner portion 52 is set to be equal to the taper angle θ2 of the outer portion 51 (θ1=θ2). In the second embodiment, as image 3 As shown, the taper angle θ1 of the interior 52 is set to be smaller than the taper angle θ2 of the exterior 51 (θ1 Figure 4 As shown, the taper angle θ1 of the inner portion 52 is set larger than the taper angle θ2 of the outer portion 51 (θ1>θ2).

[0059] In both cases above, the outer periphery 52a of the inner portion 52 is provided in a tapered shape, so the gap between the roller 53 and the inner portion 52 formed by the tapered shape of the cam surface 51a can be reduced. Thus, when torque is transmitted, the inclination of the pinion tube 4 , that is, the inclination of the inner portion 52 relative to the roller 53 can be reduced. Thus, it is possible to prevent the roller 53 and the inner portion 52 from contacting each other only at the bottom of the cam. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com