System for collecting and utilizing compressed-air type wave energy of ship swaying lever

An energy harvesting and lever technology, which is used in liquid variable capacity machinery, piston pumps, pump devices, etc., can solve the problems of increased manufacturing costs, low energy conversion equipment, and inability to meet the requirements of reducing corrosion resistance. Avoid direct impact and erosion, reduce the effect of investment in capital costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

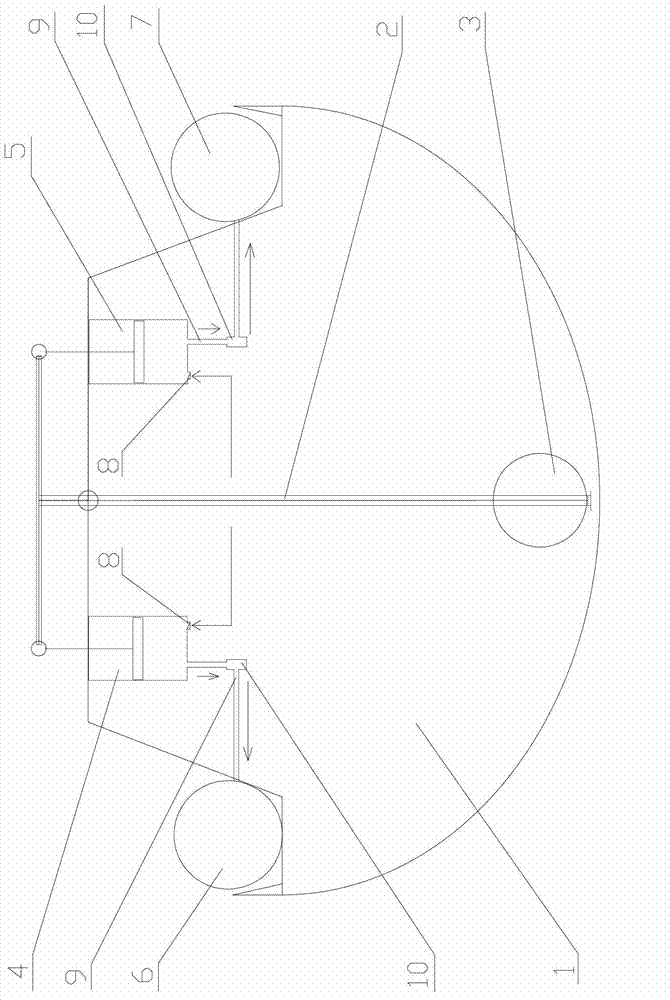

[0024] Below in conjunction with accompanying drawing, technical scheme of the present invention will be further described:

[0025] The ship swing lever compressed air type wave energy collection and application system of the present invention includes an energy conversion and collection device that converts the kinetic energy of the left and right swings of the ship body 1 into compressed air energy and collects it. The energy conversion and collection device is mainly composed of a T-shaped lever 2, a counterweight 3, The left cylinder 4 and the right cylinder 5 (the same type and specification), the left air storage tank 6 and the right air storage tank 7 (the same size), valves and pipelines 9 constitute.

[0026] The vertical bar of the T-shaped lever 2 is located on the center line of the hull 1 and the hull 1 is divided into two parts, left and right. The upper part of the vertical rod is hinged on the hull 1, and the counterweight 3 is arranged at the bottom of the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com