Steam temperature observation optimal control method for supercritical unit

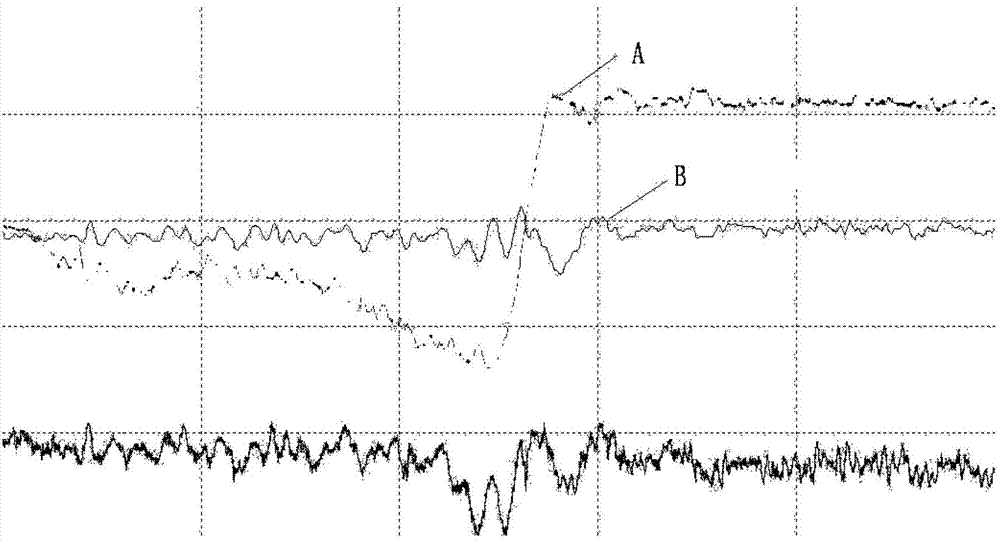

A supercritical unit, optimized control technology, applied in the control of superheat temperature, steam superheat, steam generation, etc., can solve the main steam temperature control system disturbance, difficult control, excessive sensitivity of the leading steam temperature, etc., to achieve the main steam temperature. The effect of reducing temperature fluctuation and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

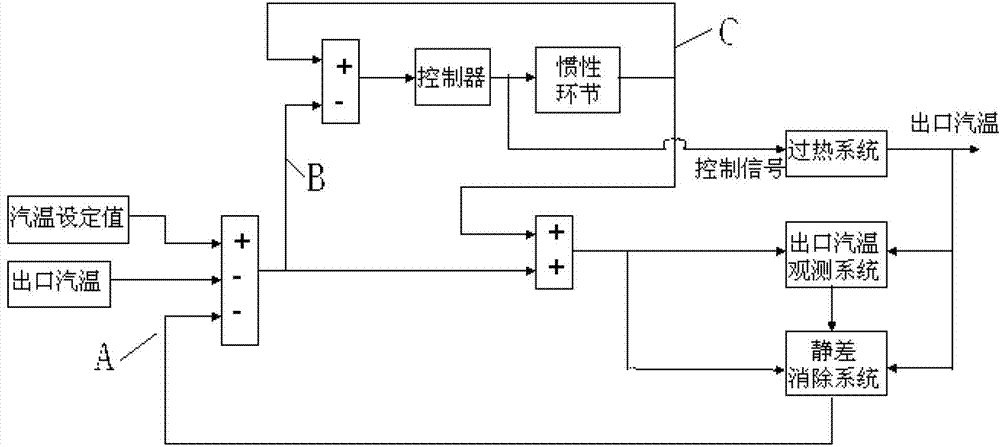

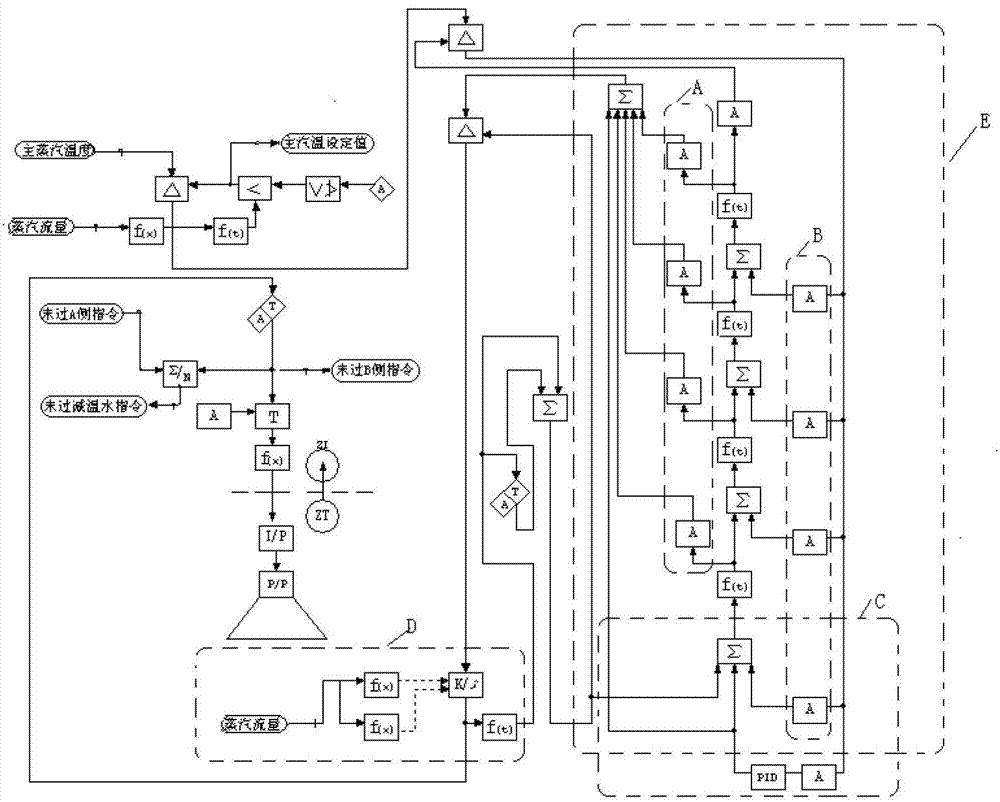

[0018] 1. Outlet steam temperature observation optimization control system

[0019] In the steam temperature control of thermal power units, the steam temperature control system of some units has the situation that the leading steam temperature is too sensitive, most of which are due to the poor installation of the measuring point, which is too close to the desuperheating water valve, so in the conventional cascade control system Among them, the ideal control effect cannot be obtained by introducing the leading steam temperature, but the effect of controlling the outlet steam temperature with a single-stage PID is even worse; the present invention proposes an outlet steam temperature observation optimization control system, which does not need to introduce the leading steam temperature, At the same time, the control effect is much better than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com