Detection method of permanent magnet motor rotor position

A permanent magnet motor, rotor position technology, applied in motor generator control, control of electromechanical transmission, electronic commutation motor control, etc. The requirements are higher

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to describe the present invention more specifically, the detection method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

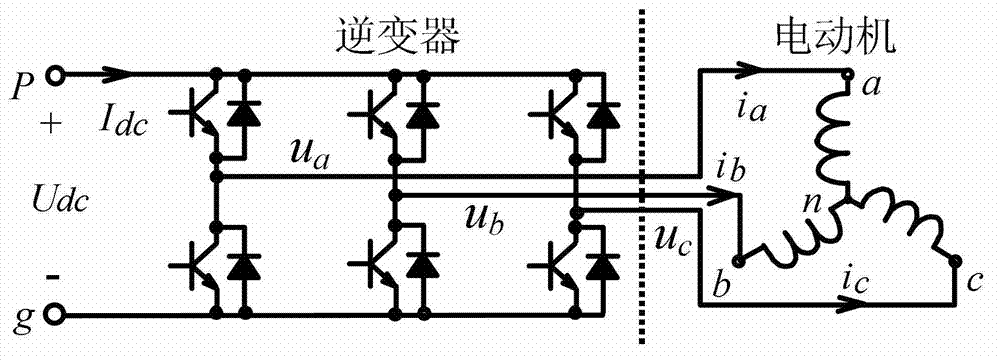

[0047] Taking a three-phase permanent magnet synchronous motor as an example, the parameters of the motor are shown in Table 1; the control structure of the motor is as follows figure 1 As shown, among them, U a , U b , U c is the three-phase terminal voltage, I a , I b , I c is the three-phase current.

[0048] Table 1

[0049] Rated power (W)

1500

Rated speed(rpm)

1000

Rated torque(N*m)

14.3

Rated current (A)

3.8

Winding Connection

Y type

Phase resistance R s (Ω)

2.15

Direct axis inductance L d (H)

0.0632

Quadrature axis inductance L q (H)

0.0919

Permanent magnet equivalent flux linkage (Wb)

0.5

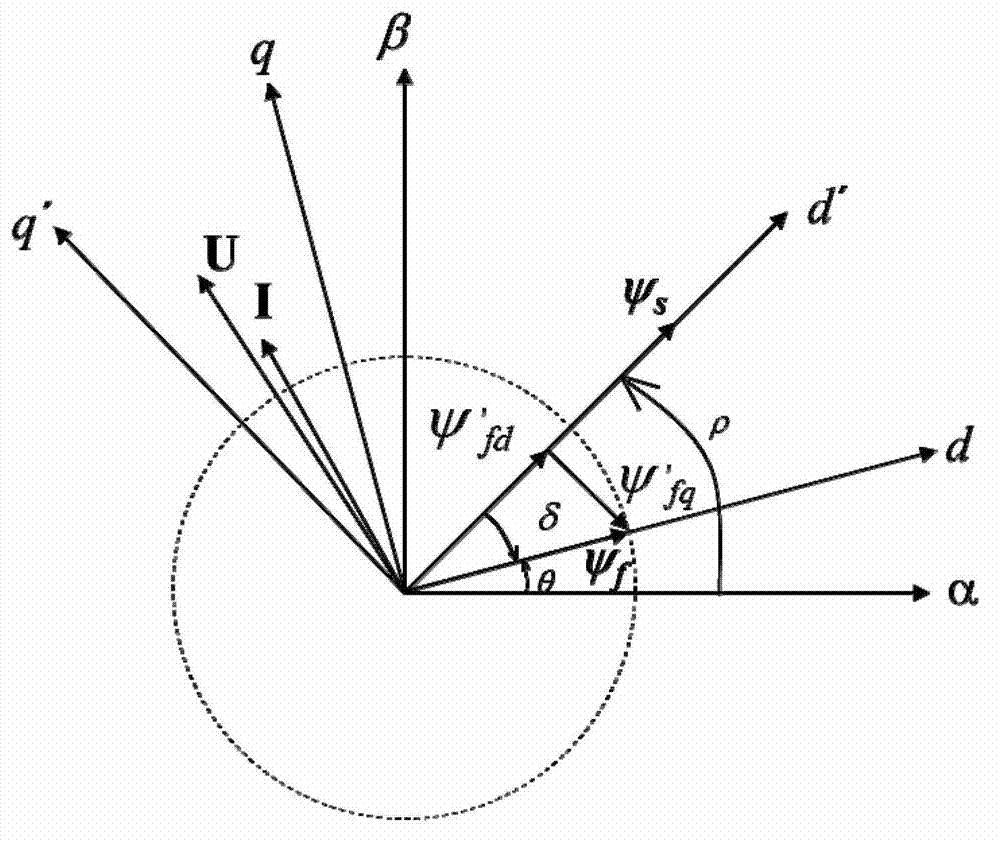

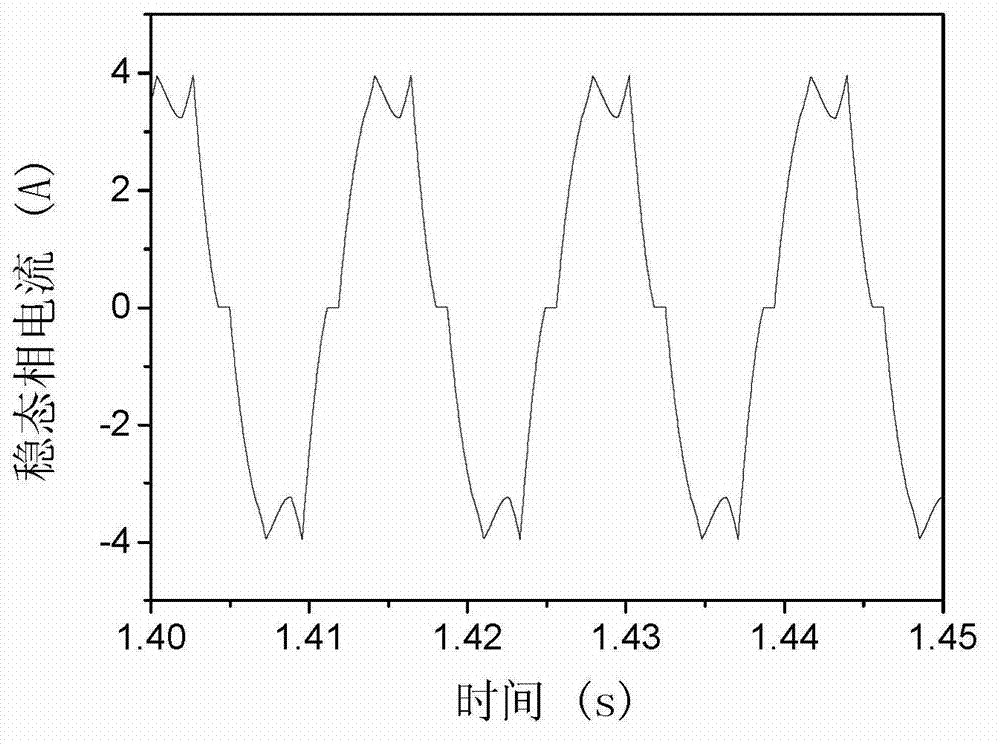

[0050] A method for detecting the rotor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com