Soldering Offset Prevention Method for Surface Mount Devices

A technology of surface mount devices and surface mount devices, which is applied in the field of anti-soldering offset of surface mount devices, can solve problems such as easy generation of tin balls, easy displacement, and chip offset, so as to avoid repair work and avoid device Offset, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0026] The inventors of the present invention have advantageously found that in the existing surface mount process, the reason why surface mount devices such as TO265 packaged devices are prone to offset is mainly due to the fact that the center of the solder paste printing is aligned with the surface mount device. The actual placement center does not coincide.

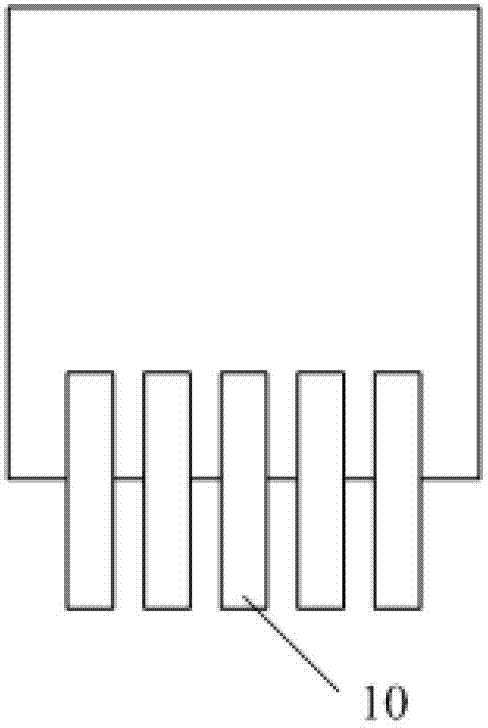

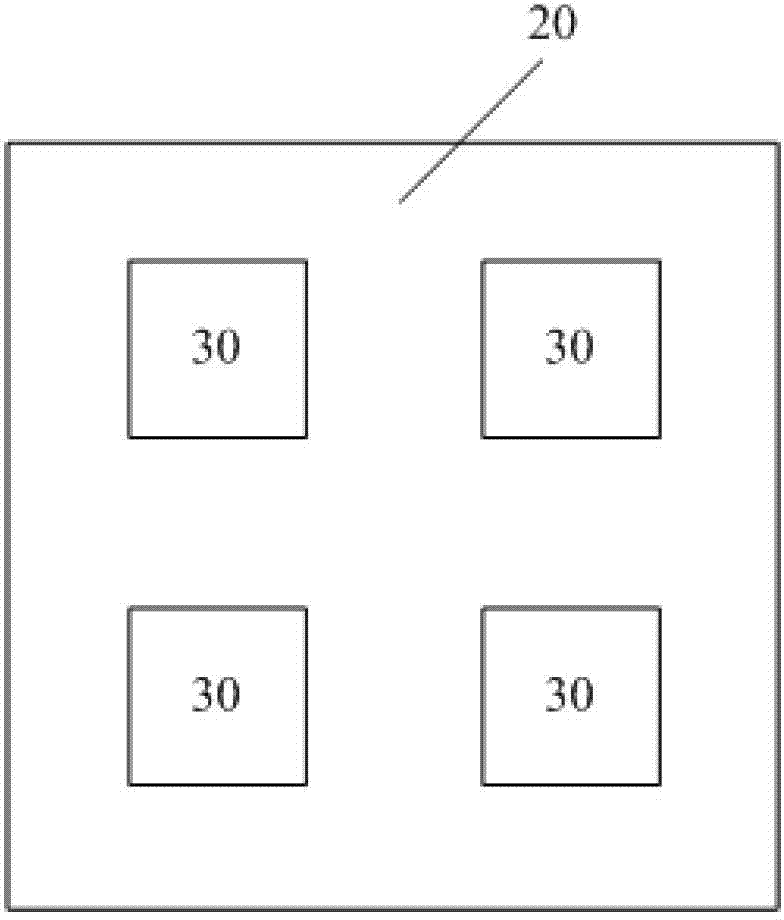

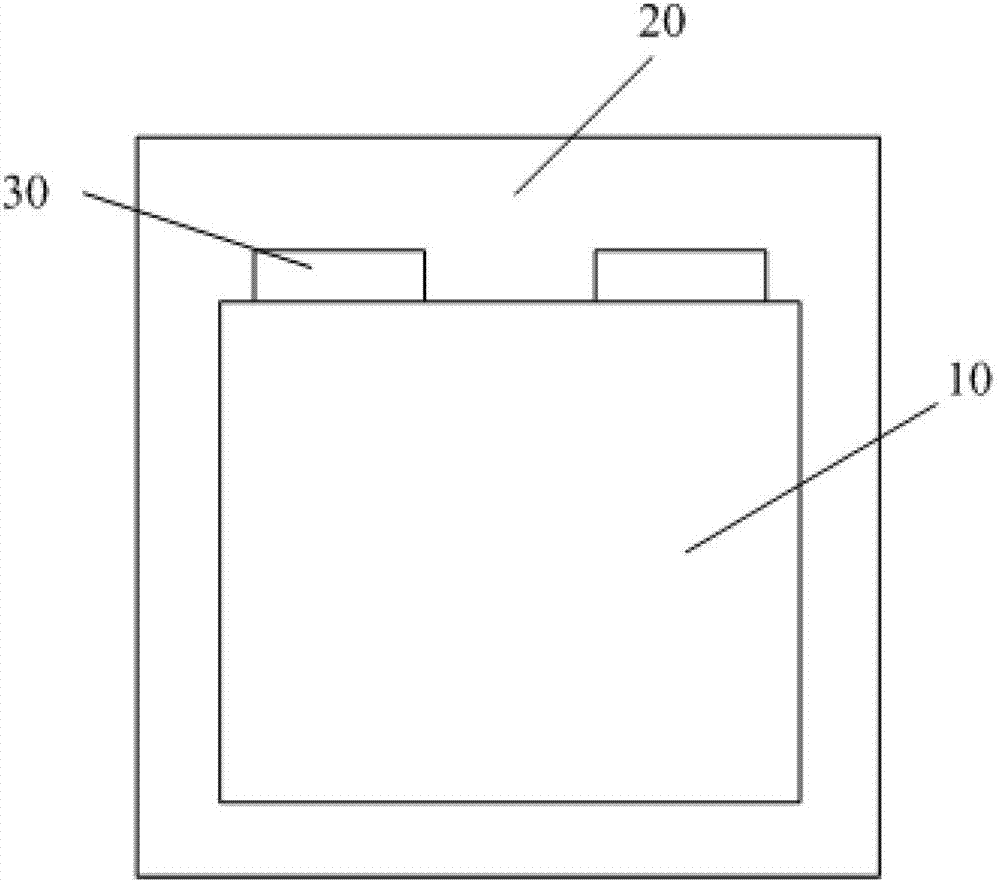

[0027] Specifically, the design of existing surface mount devices such as TO265 package devices and the like is that, at the central position of the pad 20 of the PCB board, a grid-shaped opening 30 is opened, and solder paste is printed on the PCB, such as figure 2 shown.

[0028] However, since the grounding pads of surface mount devices such as TO265 packaged devices are generally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com