Method for controlling sodium nitrate quality in vacuum cooling crystallization technology

A technology of vacuum cooling and product quality, applied in solution crystallization, alkali metal nitrate, chemical instruments and methods, etc., can solve problems such as low sodium nitrate content, products that do not meet the requirements of high-quality products, and difficult to remove.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment includes the following steps:

[0024] (1) By controlling the parameters of the evaporation system, the content of sodium nitrate in the evaporated high-temperature mother liquor is 900g / l (the temperature of the high-temperature mother liquor is 135°C, the content of sodium chloride is 75g / l, and the content of sodium sulfate is 30g / l), and then sent to Three-stage vacuum cold crystallizers connected in series for cooling and crystallization;

[0025] The feed liquid temperatures of the three-stage series crystallizers are 77±1°C, 55±1°C, and 35±1°C respectively;

[0026] (2) Add water during the vacuum cooling and crystallization process to suppress the crystallization of sodium chloride and sodium sulfate during the vacuum cooling and crystallization process. The volume of additional water is 18% of the volume of the high-temperature mother liquor (all added to each stage of crystallizer), Obtain sodium nitrate slurry;

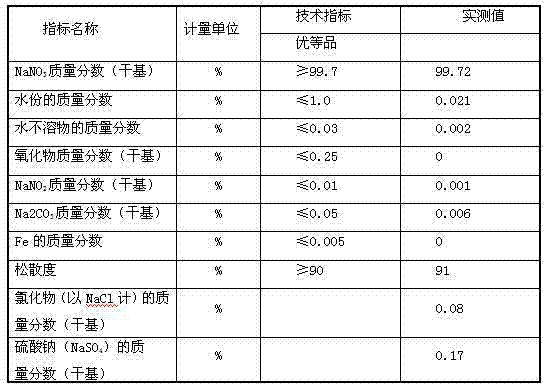

[0027] (3) In the elutriatio...

Embodiment 2

[0031] This embodiment includes the following steps:

[0032] (1) By controlling the parameters of the evaporation system, the content of sodium nitrate in the evaporated high-temperature mother liquor is 950g / l (the temperature of the high-temperature mother liquor is 140°C, the content of sodium chloride is 85g / l, and the content of sodium sulfate is 35g / l), and then sent to Four-stage vacuum cold crystallizers connected in series for cooling and crystallization;

[0033] The feed liquid temperatures of the four-stage series crystallizers are 85±1°C, 60±1°C, 50±1°C, and 35±1°C respectively;

[0034] (2) Add water during the vacuum cooling and crystallization process to inhibit the crystallization of sodium chloride and sodium sulfate during the vacuum cooling and crystallization process. The volume of additional water is 22% of the volume of the high-temperature mother liquor (all added to each stage of crystallizer), Obtain sodium nitrate slurry;

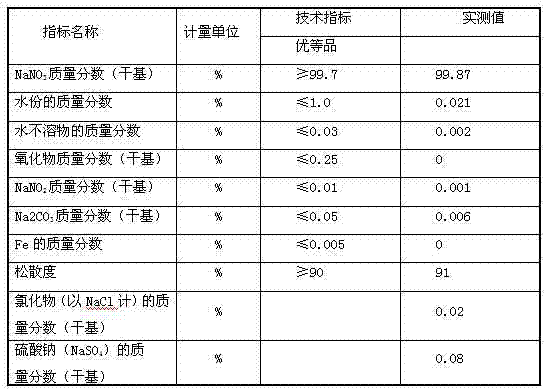

[0035] (3) In the elutr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap