Detachable fiberglass tubular trawl truss

A kind of glass fiber reinforced plastic and glass fiber reinforced plastic technology, applied in fishing boats and other directions, can solve the problem that log poles and bamboo poles are difficult to meet the requirements of strength and size, high fluidity, rapidity and mobility, and truss poles do not meet the survey work. and other problems, to achieve the effect of small specific gravity, anti-aging friction resistance, easy positioning and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

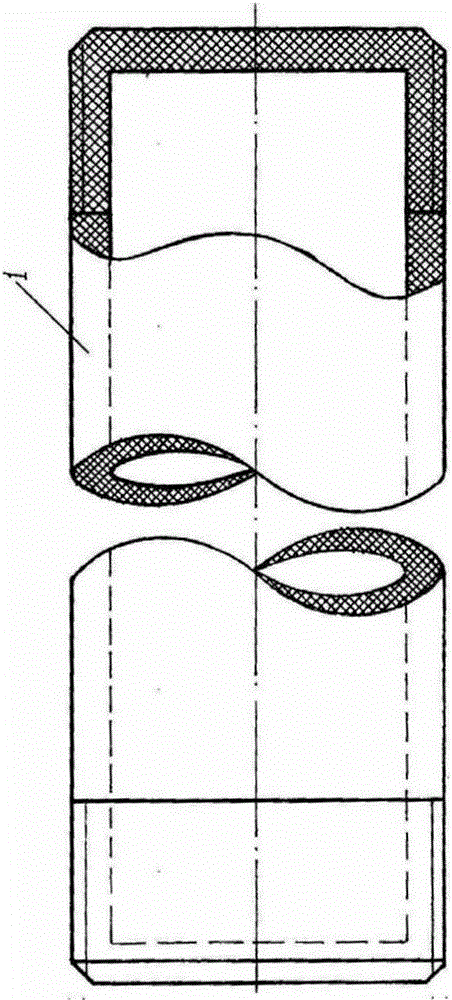

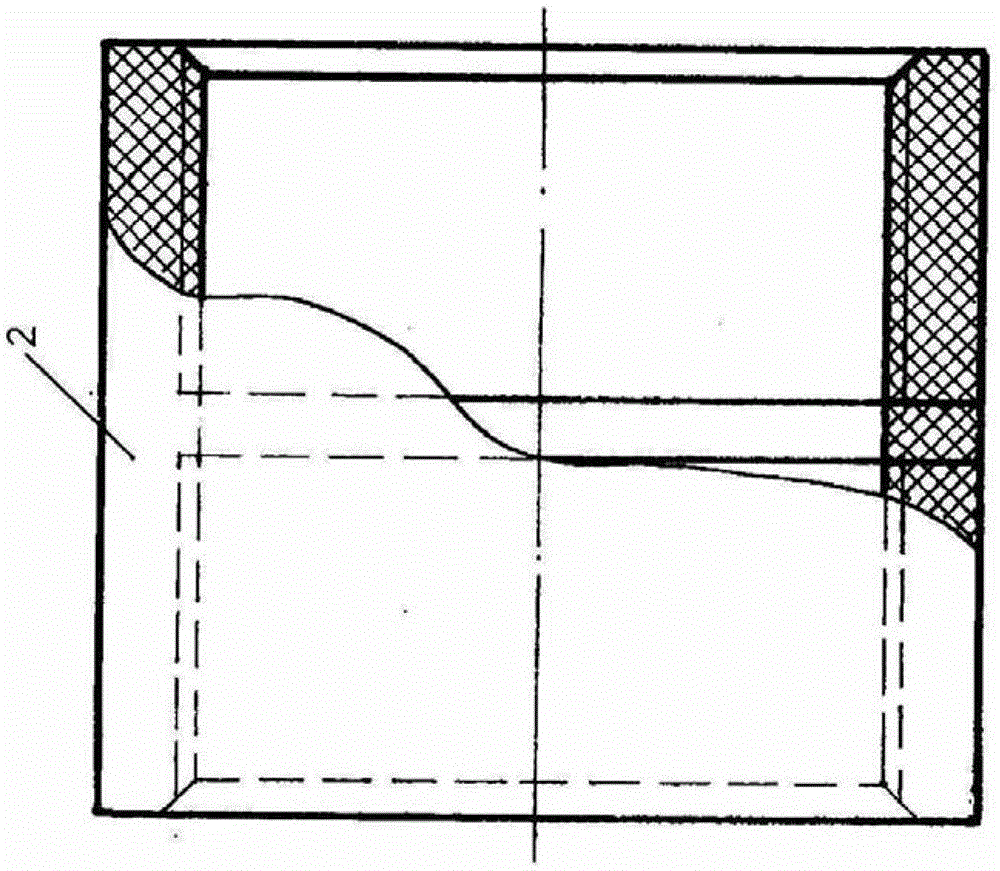

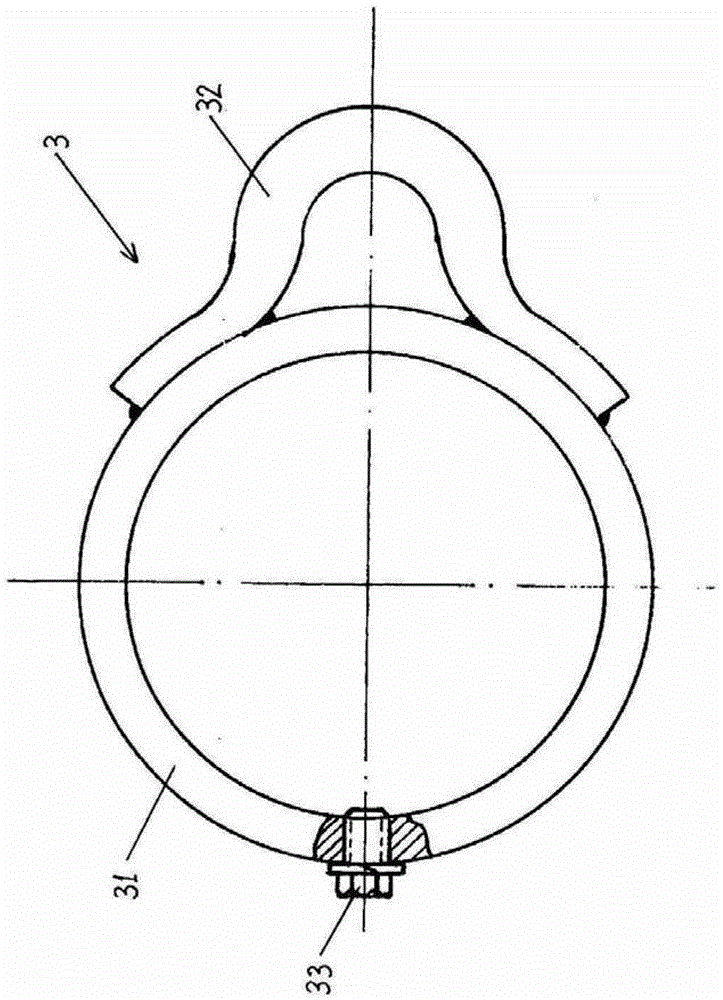

[0019] The detachable FRP-shaped trawl truss of the present invention includes a rod body and a fork frame positioning device, and the rod body includes a plurality of FRP steel pipes 1 and a plurality of FRP connecting sleeves 2 . Such as figure 1 As shown, the outer diameter of each glass steel pipe 1 is 50-80mm, preferably 60.3mm, the pipe wall thickness is 6-10mm, preferably 8mm, and the length of each is 1-2m, which can be selected from 1.00m, 1.20m, 1.40m, 1.50m, 1.60m, 1.70m, 1.80m and other sizes, the material is epoxy glass fiber reinforced plastic. The end of the glass steel pipe 1 is processed with an external thread portion, and the two ends are closed with the same glass fiber reinforced plastic material. Such as figure 2 As shown, the two ends of the FRP connecting sleeve 2 are respectively processed with internal thread parts, and the external thread part on the glass steel pipe 1 matches the internal thread part on the glass tube connecting sleeve 2 . Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com