High-wear-resistant cement-based self-leveling mortar and preparation method thereof

A self-leveling mortar and cement-based technology, which is applied in the field of high wear-resistant cement-based self-leveling mortar and its preparation, can solve the problem of low surface wear resistance and achieve good surface wear resistance and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A high wear-resistant cement-based self-leveling cement mortar, its raw material formula is as follows in Table 1:

[0021]

[0022] Use the raw materials in the above table to make mortar, and the preparation method is as follows:

[0023] 1) Anti-rust treatment of iron sand: put iron sand in boiling sodium hydroxide solution with a concentration of 5wt% for 10 minutes, separate iron sand, and dry;

[0024] 2) Put the antirust-treated iron sand and other components of self-leveling mortar into the mixing kettle according to the ratio, stir for 20-50 minutes, and then discharge and pack.

Embodiment 2

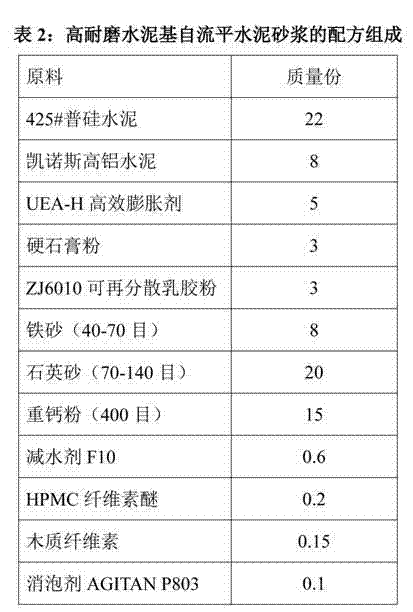

[0026] A high wear-resistant cement-based self-leveling cement mortar, the composition of its raw materials is as follows in Table 2:

[0027]

[0028] Use the raw materials in the above table to make mortar, and the preparation method is as follows:

[0029] 1) Anti-rust treatment of iron sand: put iron sand in boiling sodium hydroxide solution with a concentration of 5wt% for 10 minutes, separate iron sand, and dry;

[0030] 2) Put the antirust-treated iron sand and other components of self-leveling mortar into the mixing kettle according to the ratio, stir for 20-50 minutes, and then discharge and pack.

Embodiment 3

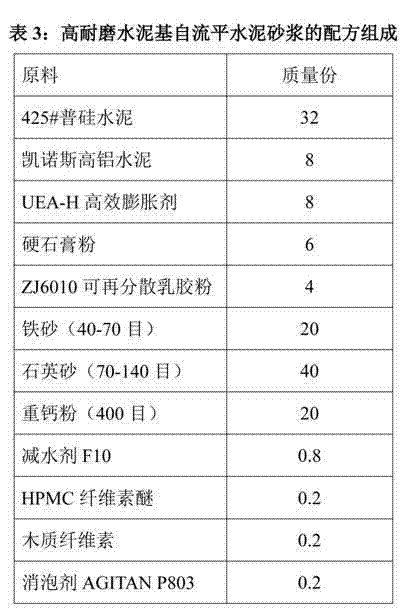

[0032] A high wear-resistant cement-based self-leveling cement mortar, its raw material formula is as follows in Table 3:

[0033]

[0034] Use the raw materials in the above table to make mortar, and the preparation method is as follows:

[0035] 1) Anti-rust treatment of iron sand: put iron sand in boiling sodium hydroxide solution with a concentration of 5wt% for 10 minutes, separate iron sand, and dry;

[0036] 2) Put the anti-rust treated iron sand and other components of self-leveling mortar into the mixing kettle according to the proportion, stir for 20-50 minutes, and then discharge and pack.

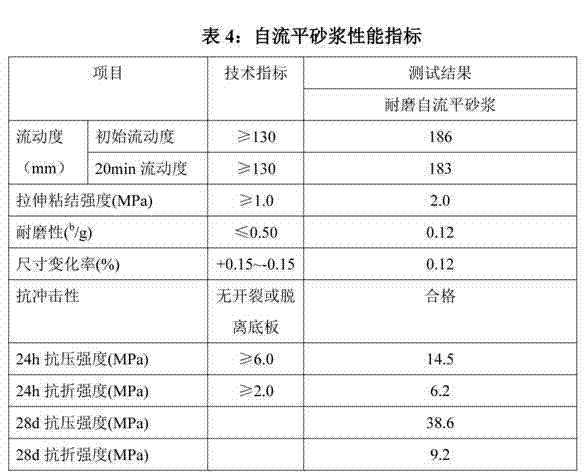

[0037] The mortar of embodiment 1 is carried out relevant performance test (the standard of test is JC / T985-2005), and its test result is as follows:

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com