Method for manufacturing decorative base material taking sodium chloride particles as main material

The technology of a sodium chloride particle and a manufacturing method is applied in the manufacturing field of decorative substrates, can solve problems such as the inability to meet the development of the national economy, and achieve the effects of easy industrial production and promotion, beautiful appearance, and wide sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present invention takes the sodium chloride particle as the manufacture method of the decoration base material of main ingredient, and the detailed steps of this manufacture method are as follows:

[0032] a, with sodium chloride granules as the basic raw material, lightly burned powder and halogen block as cement, the weight ratio between the sodium chloride granules and lightly burned powder is 7:2, and the lightly burned powder The molar ratio between the halogen block and the two is 5:1;

[0033] The mass percentage of the sodium chloride particles is ≥ 91%, and the particle size ranges from 0.1 to 3.5mm; the mass percentage of the active magnesium oxide in the lightly burned powder is 80 to 85%; the magnesium chloride in the halogen block The mass percentage content is 40-50%;

[0034] b. Mixing of sodium chloride and lightly burned powder: prepare various raw materials according to the ratio of raw materials in step a, first place the prepared basic raw mater...

Embodiment 2

[0040] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0041] In step a: using sodium chloride granules as basic raw material, lightly burned powder and halogen block as cement, the weight ratio between the sodium chloride granules and lightly burned powder is 4:1, and the lightly burned powder The molar ratio between burnt powder and halogen block is 4:1;

[0042] In step c: be mixed with the magnesium chloride solution that Baume degree is 25 ° of Be;

[0043] In step d: add for the first time the solution that accounts for 28% of the total volume of the magnesium chloride solution;

[0044] In step e: molding time is 5h;

[0045] In step f: the initial maintenance at room temperature for 9 hours, demoulding after the initial maintenance, and then continued maintenance for 10 days to obtain the decorative base material of the product sodium chloride particles as the main ingredient.

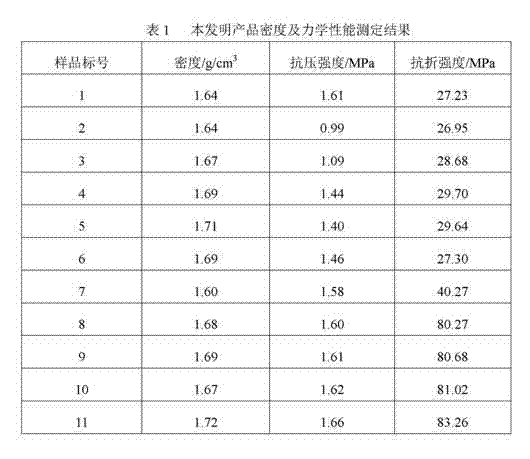

[0046] For the density and mechanical properties of the product o...

Embodiment 3

[0047] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0048] In step a: using sodium chloride granules as basic raw material, lightly burned powder and halogen block as cement, the weight ratio between the sodium chloride granules and lightly burned powder is 6:1, and the lightly burned powder The molar ratio between burning powder and halogen block is 6:1;

[0049] In step c: be mixed with the magnesium chloride solution that Baume degree is 24 ° of Be;

[0050] In step d: first add the solution that accounts for 29% of the total volume of magnesium chloride solution;

[0051] In step e: molding time is 7h;

[0052] In step f: initial maintenance at room temperature for 10 hours, demoulding after the initial maintenance, and then continued maintenance for 11 days to obtain a decorative substrate with sodium chloride particles as the main ingredient.

[0053] For the density and mechanical properties of the product obtained in Example 3, see the experi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com