PVB (polyvinyl butyral) film having sound-insulating property and preparation method thereof

A technology of sound insulation performance and diaphragm, applied in the field of PVB diaphragm and its preparation, can solve problems such as insufficient noise reduction effect, and achieve the effects of reducing coupling frequency, good effect and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

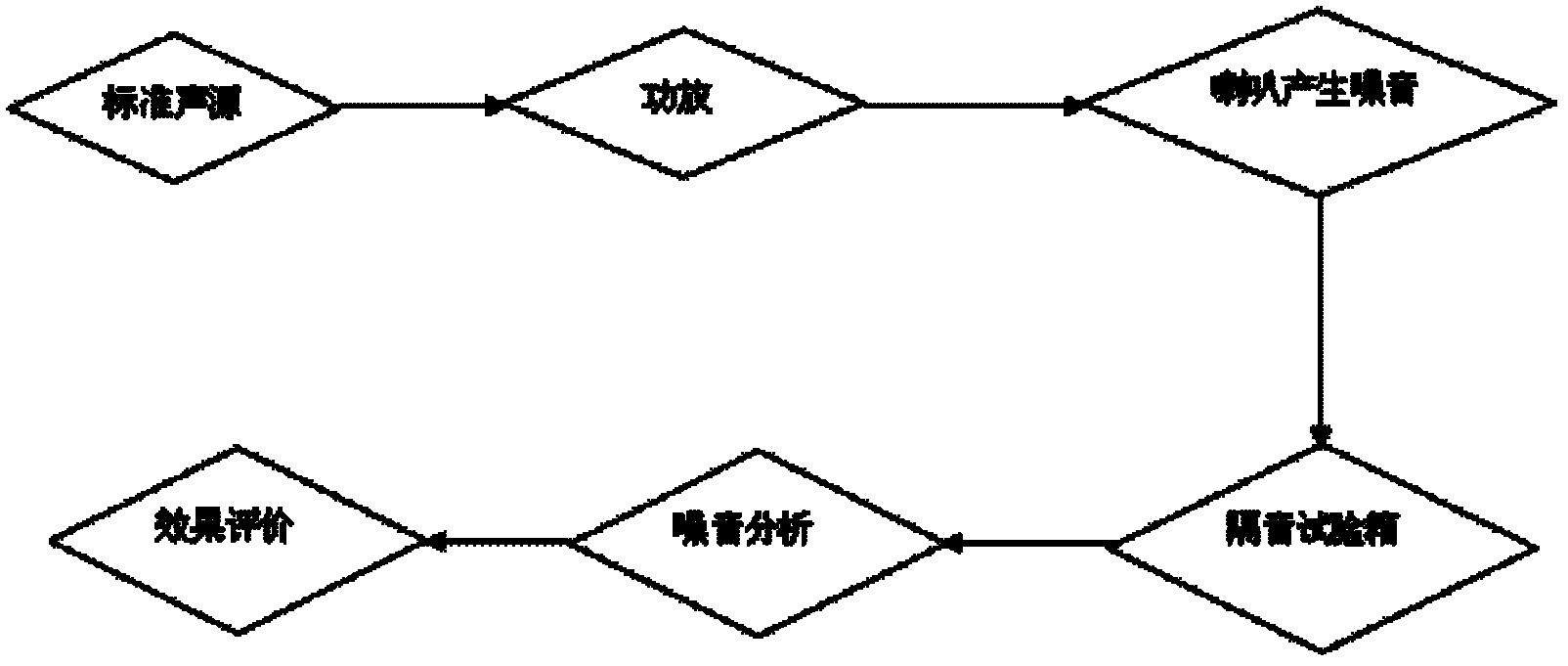

Method used

Image

Examples

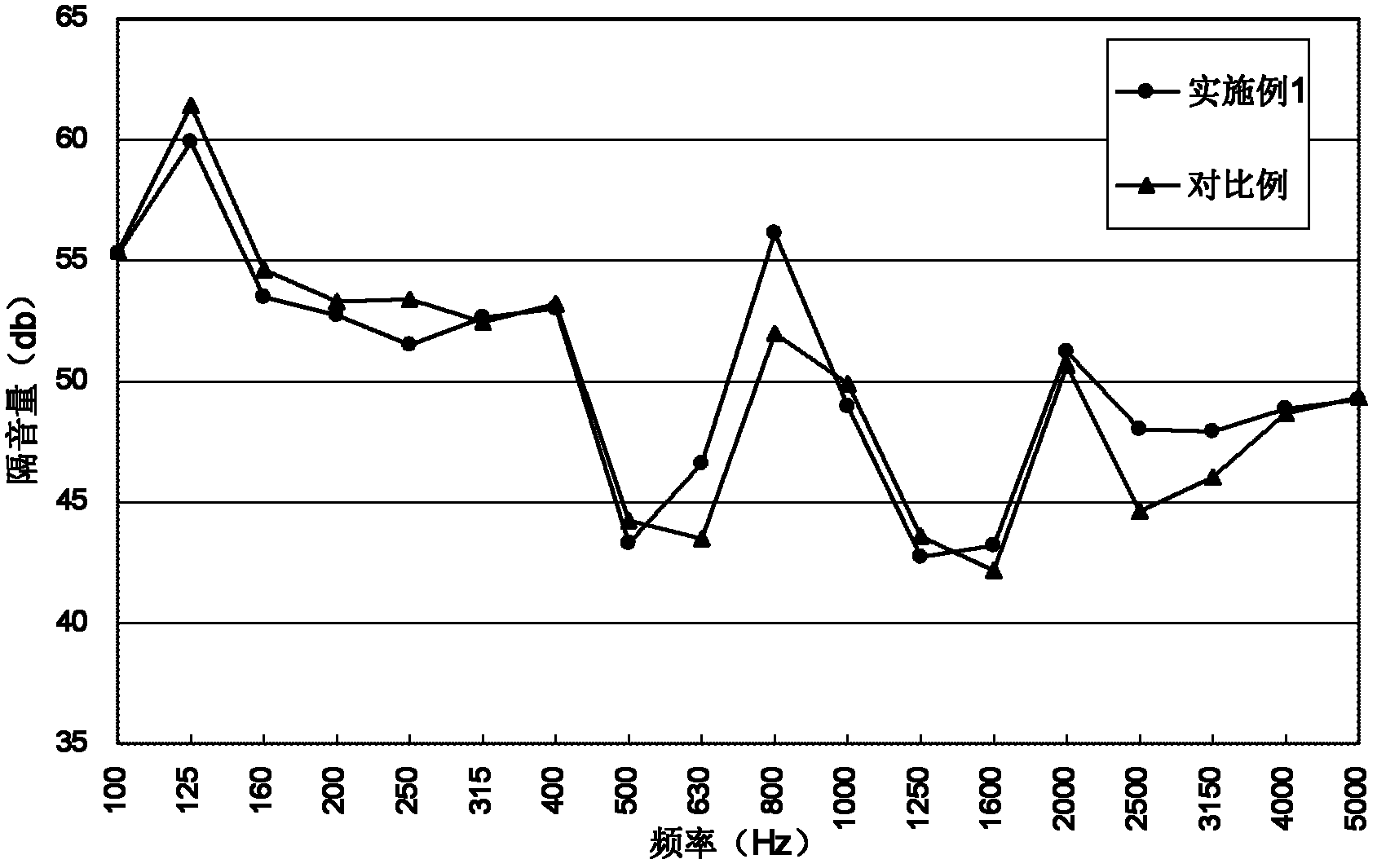

Embodiment 1

[0032] Take polyethylene glycol 200: 100g, 3G7: 300g, PVB resin powder: 600g, antioxidant 1076: 10g, ultraviolet absorber 327: 5g, after uniform mixing in a high-speed mixer, pass through a twin-screw extruder at 160 The temperature is plasticized at a temperature of ℃, and the PVB film with sound insulation performance is obtained by forming a film through a mold.

Embodiment 2

[0034] Take polyethylene glycol 600: 200g, 4GO: 300g, PVB resin powder: 500g, antioxidant 1135: 16g, ultraviolet absorber UV-P: 5g, after uniform mixing in a high-speed mixer, pass through a twin-screw extruder Plasticized at a temperature of 140° C., and formed into a film through a mold to obtain the PVB film with sound insulation performance.

Embodiment 3

[0036] Take polyethylene glycol 800: 200g, DBS: 200g, PVB resin powder: 700g, antioxidant 1076: 15g, ultraviolet absorber 327: 8g, after uniform mixing in a high-speed mixer, through a twin-screw extruder in Plasticized at a temperature of 170° C., and formed into a film through a mold to obtain the PVB film with sound insulation performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com