Antistatic color gel coat and preparation method thereof

An antistatic and antistatic agent technology, applied in the direction of conductive coatings, multi-color effect coatings, coatings, etc., can solve problems such as difficult production, unstable gel coat gelation and curing, and difficult control of gelation and curing time. Uniform thickness, uniform and controllable surface resistance, and rich colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0019] The antistatic colored gel coat of the present embodiment is green, and it is made of the following components by weight:

[0020] 100 parts of matrix resin; among them, 70 parts of medium-active matrix resin, whose molecular weight distribution index (Mw / Mn) ≤ 2.5, specifically adopts Changxing company's model 2504 ortho-phthalic matrix resin, in which the moles of unsaturated dibasic acid It is 50% of the total moles of dibasic acids; 30 parts of highly active matrix resin, the molecular weight distribution index (Mw / Mn) ≤ 2.5, specifically the isophthalic matrix resin model RX130 of Nisshin Company, of which no The mole number of saturated dibasic acid is 70% of the total mole number of dibasic acid.

[0021] 12 parts of styrene.

[0022] 20 parts of talcum powder.

[0023] Fumed silica 2 parts.

[0024] 0.15 part of thixotropic stabilizer, what adopt is the PR600 type thixotropic stabilizer produced by Clariant Company.

[0025] KJ-120 antistatic agent 4 parts. ...

Embodiment 2~ Embodiment 5)

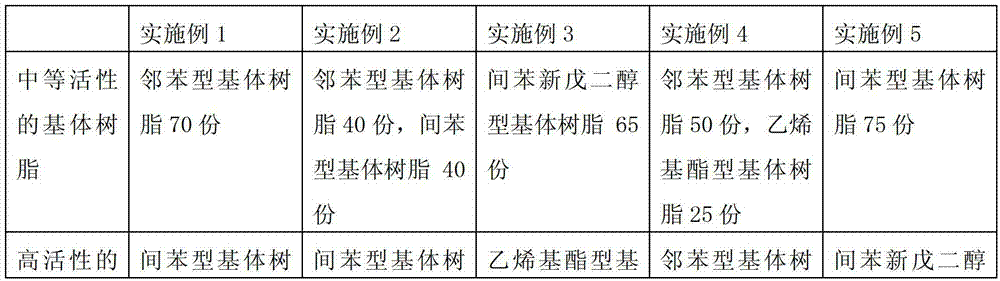

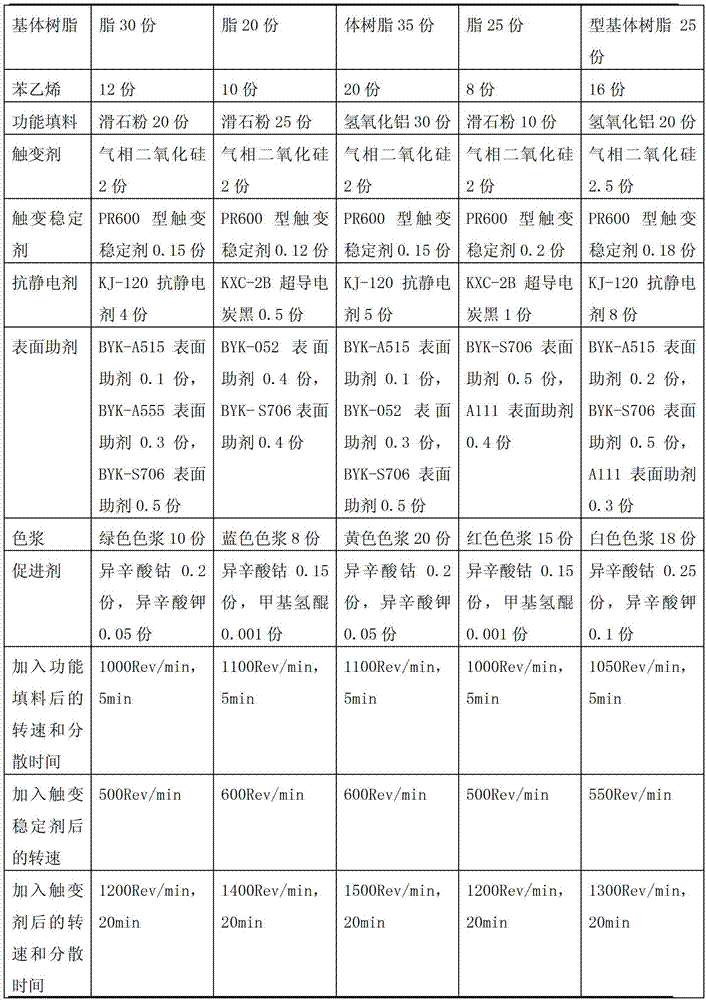

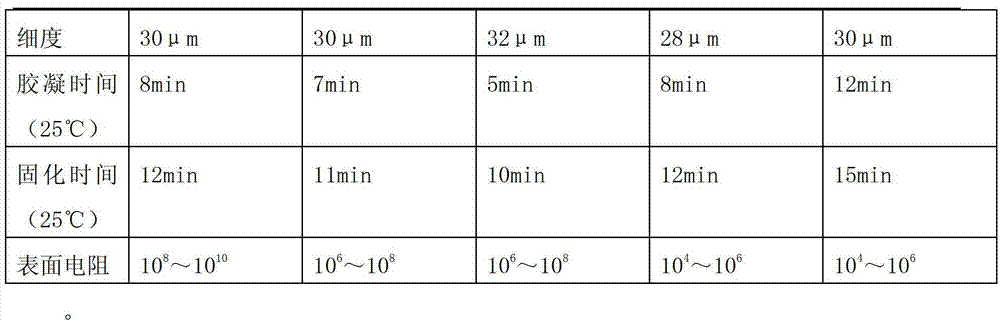

[0035] Each embodiment is basically the same as Embodiment 1, and the differences are shown in Table 1.

[0036]

[0037]

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com