Microbial fermentation method for promoting iris japonica dry piece to rapidly generate fragrance

A technology of dried iris slices and iris, which is applied in the field of catalytic fermentation of iris aging, can solve problems such as difficult industrial applications, and achieve the effects of shortening the time of aging and producing aroma, reducing production costs, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

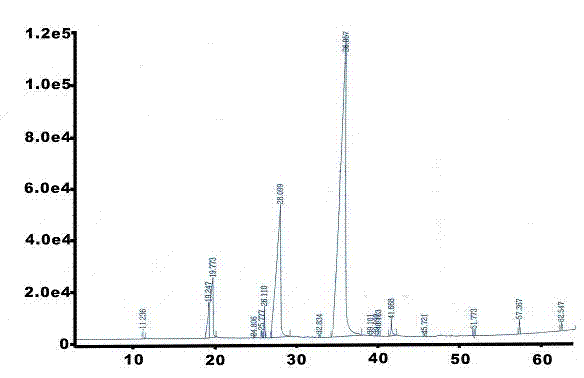

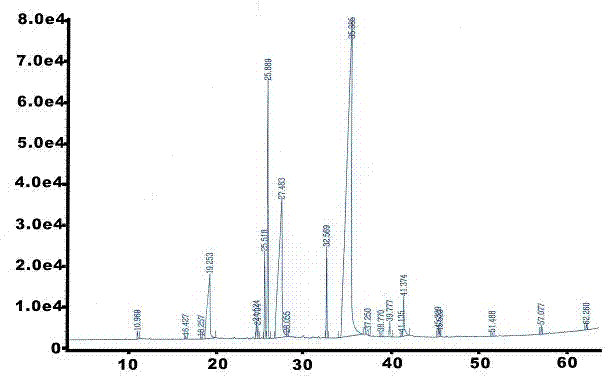

[0019] Fresh iris rhizome 10kg. Among them, take out 8 kg of fresh iris rhizomes, slice them, dry them, crush them, and then take 2 kg from the iris rhizome powder, and mix them with 20 g of iris dry powder that has been naturally fermented for 3 years and has a good aroma, and 1 g of finely ground NaNO 2 Mix the powder evenly, put it into the fermentation room, control the temperature at 37°C, keep the humidity > 95%, and ferment for 30 days. The fermented iris powder is distilled in water, and the distilled fat is tested by GC. The results are shown in figure 2 , Table 1; take out 2kg of fresh iris rhizomes and beat them into pulp with a pulverizer, distill in water, and use GC to check the distilled fat, the results are shown in figure 1 ,Table 1.

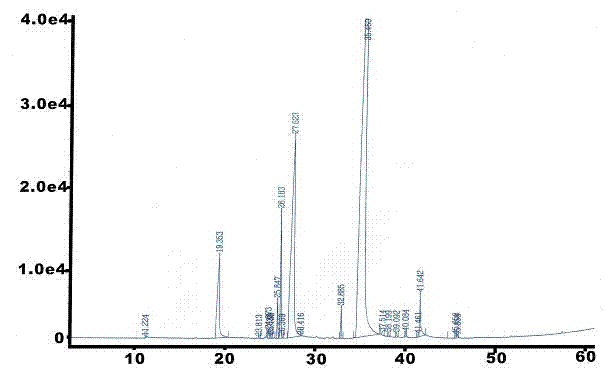

[0020] As a reference standard, take 3 to 5 years of natural fermentation and crush the dry iris slices with good aroma, take 2kg of water for distillation, and test the distilled fat by GC. The results are shown in image 3 ...

Embodiment 2

[0026] Take 4kg of dried iris flakes that have been naturally fermented for 1 year and have no aroma, and crush them. Among them, take 2kg and mix them with 20g of iris dry powder that has been naturally fermented for 3 years and has a good aroma and 0.5g of finely ground NaNO 2 Mix the powder evenly, put it into the fermentation room, control the temperature at 30°C, keep the humidity > 95%, and ferment for 15 days. The fermented iris powder is distilled in water, and the distilled fat is tested by GC. The results are shown in Figure 5 ; Take another 2 kg of dried iris slices from the same batch above that have been naturally fermented for 1 year and have no aroma, and are distilled by water distillation. The distilled fat is tested by GC, and the results are shown in Figure 4 ,Table 2.

[0027] Similarly, with image 3 As a comparison standard, it is shown in Table 2 below.

[0028] Table 2 The method of the present invention and the comparison of the GC spectra of the...

Embodiment 3

[0032] Use the dried iris flakes that have been naturally fermented for 3 to 5 years, have no mildew on the surface and have a good aroma, as the strain, use the ground nitrite as the catalyst, and crush the dried iris flakes to be fermented. The weight ratio of the fermented iris dry powder is 1%, the weight ratio of the catalyst and the iris dry powder to be fermented is 0.01%, the strain and the catalyst and the iris dry powder to be fermented are mixed evenly in the form of dry material, and packed into a sack that can hold 5kg of the iris dry powder and tightened , so that the amount of each batch of sacks is the same, each layer is laid flat on the stand of the fermentation room, leaving a gap between the sacks to facilitate air flow, and the temperature is 40 ℃, and the humidity is greater than 95%. Continue to ferment for 30 days , for large-scale fermentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com