Device and method for preparing large-size light alloy semi-solid billet

A preparation device and light alloy technology, which are applied in the field of light alloy semi-solid billet preparation device, can solve the problems of slow speed of large-size light alloy semi-solid billets, and achieve the goal of improving preparation speed, improving spheroidization, and large pulping capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

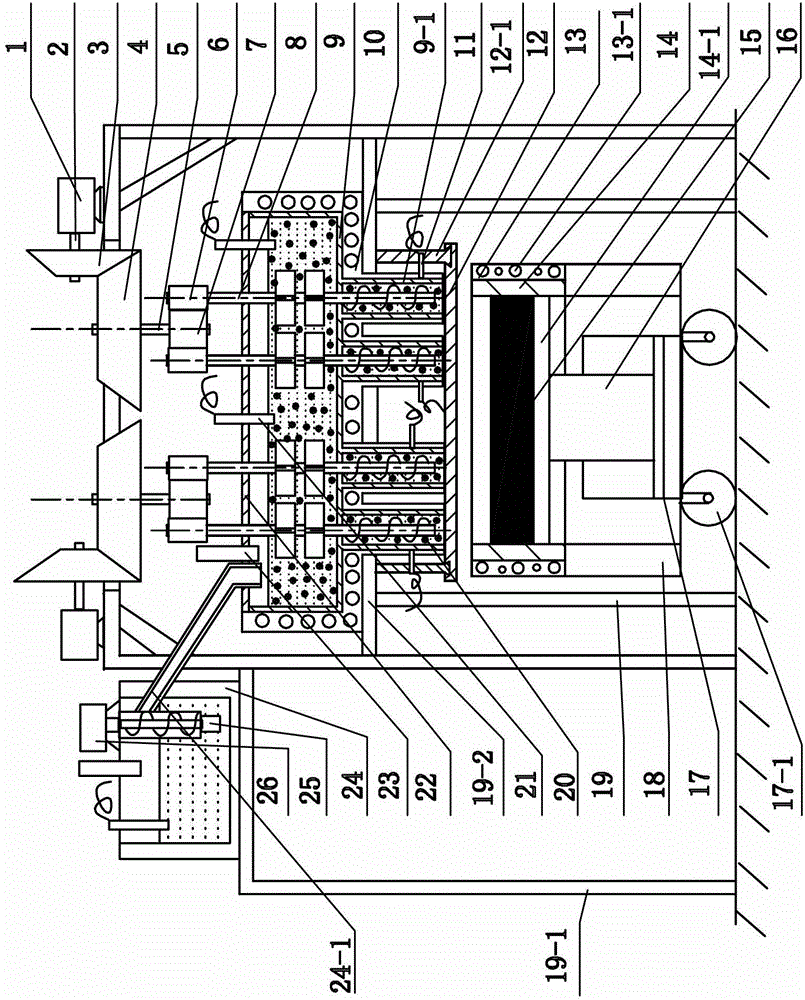

[0013] Specific implementation mode 1: Combination Figure 1-Figure 6 In this embodiment, a large-size light alloy semi-solid billet preparation device includes a 2N stirring propeller 8, the stirring propeller 8 includes a blade shaft, a small screw blade and a plurality of large blades, and the device also includes a stirring chamber 9. The first heating device 10, the baffle mechanism 12, the mobile workbench 17, the equipment frame 19, the frame bracket 19-1, the half-type cover 22, the protective gas delivery pipe 23, the electric furnace 24, the feeding pipe 24-1 , Screw pump 25, second motor 26, N first motors 1, N first gear shafts 2, N first bevel gears 3, N second bevel gears 4, N second gear shafts 5, N Two second spur gears 7, 2N first spur gears 6, 2N stirring propellers 8, 2N round tubes 9-1, a plurality of first thermocouples 11 and a plurality of second thermocouples 21, the baffle mechanism 12 includes The first hydraulic cylinder 12-1, the movable baffle 12-2 ...

specific Embodiment approach 2

[0015] Specific implementation manner two: combination figure 1 To illustrate this embodiment, a large-size light alloy semi-solid billet preparation device, the mobile workbench 17 includes a second heating device 13, a cooling mechanism 13-1, a slurry collection device 14, a moving plate 14-1, and a second The hydraulic cylinder 16, the support 18 and a plurality of universal wheels 17-1; the slurry collection device 14 is a hollow cavity, the slurry collection device 14 is provided with a second heating device 13 on the outer side, and the slurry collection device 14 is provided inside There is a moving plate 14-1, the slurry collecting device 14 is arranged on the top of the bracket 18, the moving plate 14-1 is fixedly connected with the extension end of the second hydraulic cylinder 16, the second hydraulic cylinder 16 is fixed at the bottom of the bracket 18, and the bottom of the bracket 18 is arranged There are multiple universal wheels 17-1, and the others are the same ...

specific Embodiment approach 3

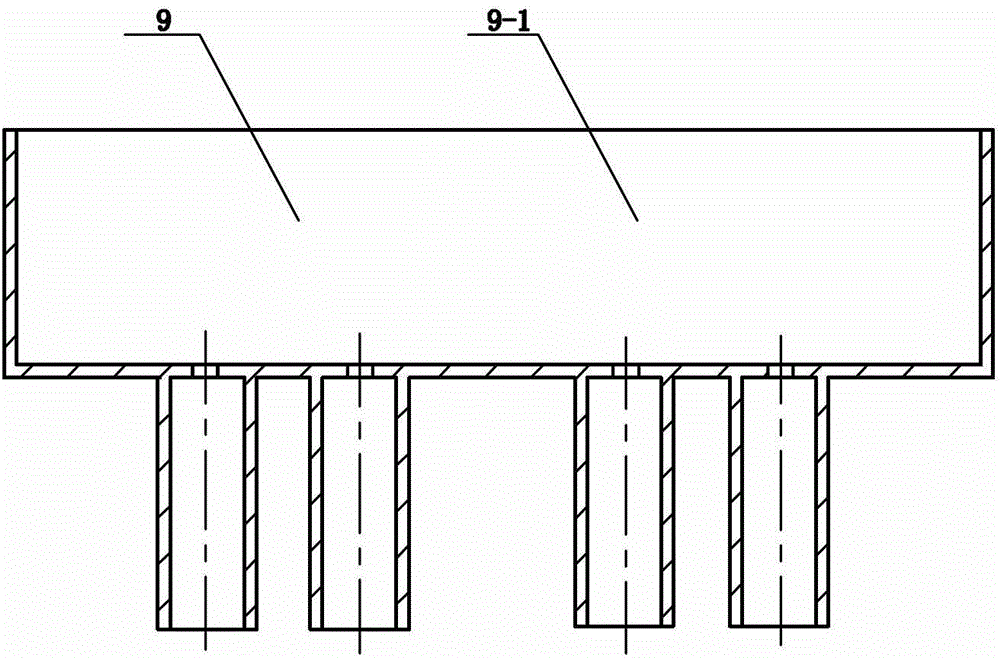

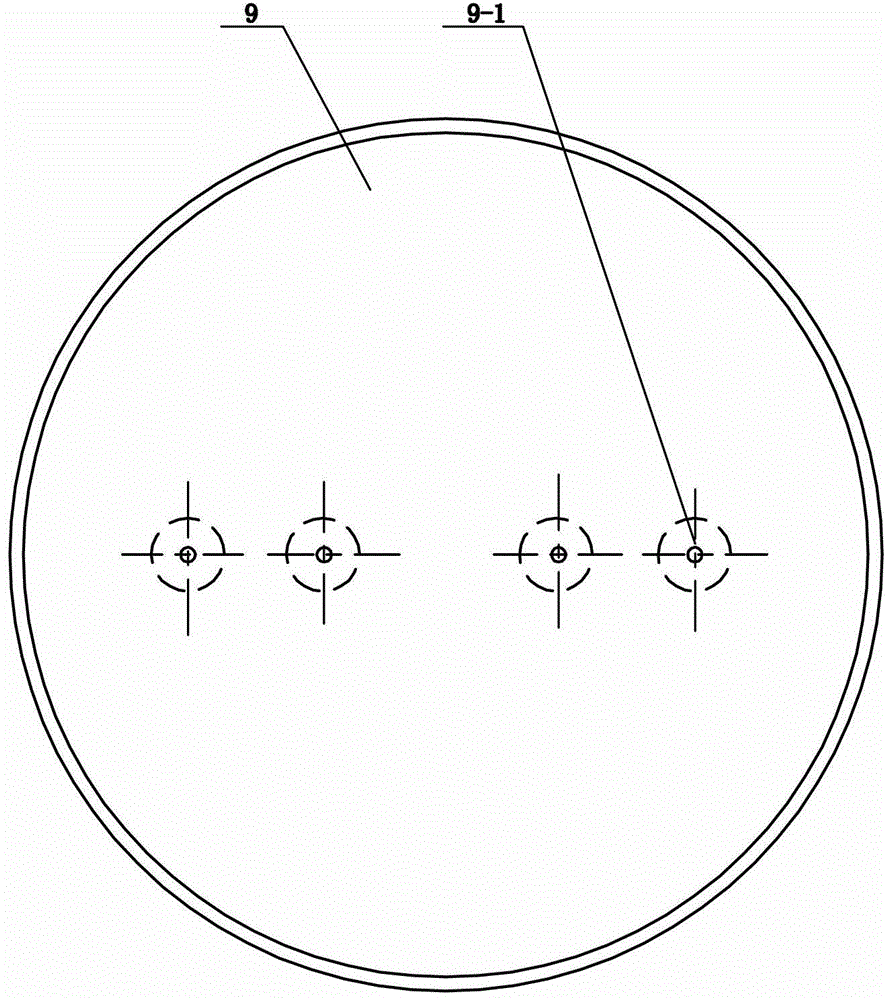

[0016] Specific implementation mode three: combination Figure 1-Figure 3 To illustrate this embodiment, a large-size light alloy semi-solid blank preparation device, the stirring chamber 9 is made of 316 stainless steel, the outer diameter of the stirring chamber 9 is 460mm, the inner diameter of the stirring chamber 9 is 400mm, and the inner diameter of the stirring chamber 9 is 400mm. The height is 380mm, the inner height of the stirring chamber 9 is 350mm, the outer diameter of the circular tube 9-1 is 60mm, the inner diameter of the circular tube 9-1 is 40mm, the height of the circular tube 9-1 is 400mm, and the bottom of the stirring chamber 9 passes There are 2N round tubes 9-1 fixed by welding, and the others are the same as the first embodiment.

[0017] Specific implementation manner 4: Combination Figure 1-Figure 3 In this embodiment, a large-size light alloy semi-solid blank preparation device is described. The first heating device 10 adopts a resistance wire wound ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com