Heading machine

A technology of roadheader and traveling mechanism, which is applied in the directions of propulsion, slitting machinery, earth-moving drilling and mining, etc., can solve the problems of high grounding specific pressure and unstable center of gravity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

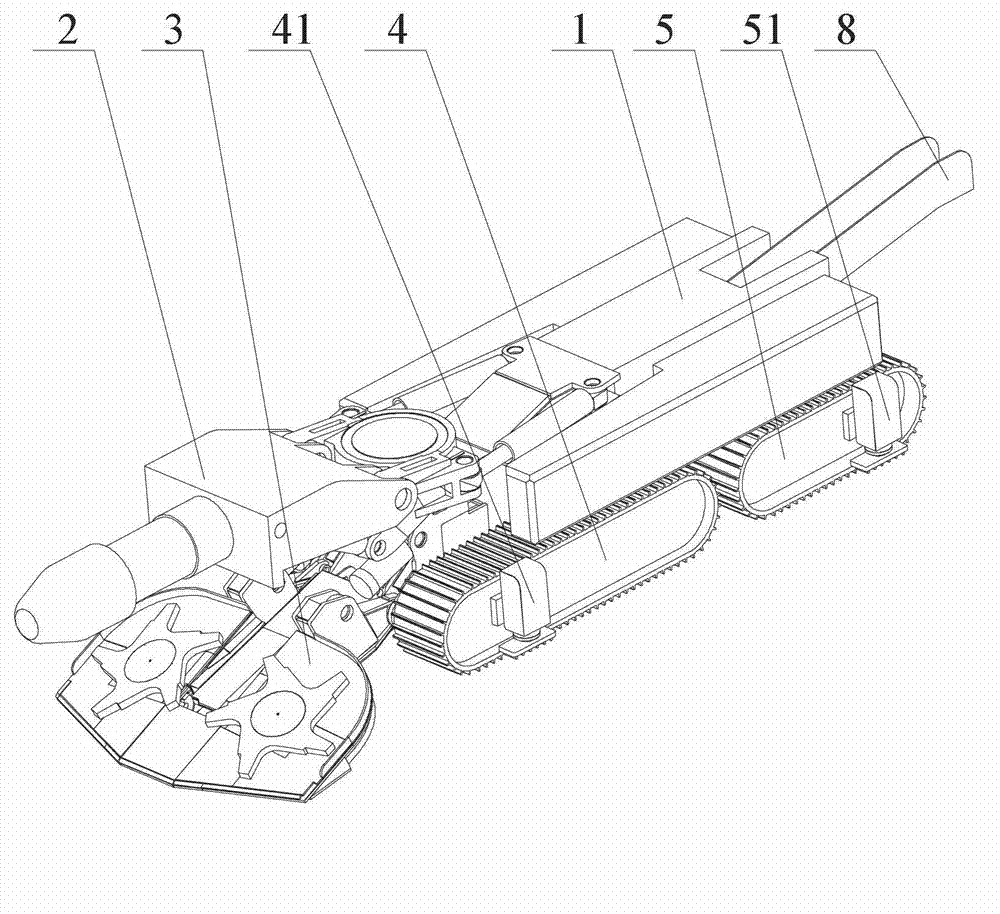

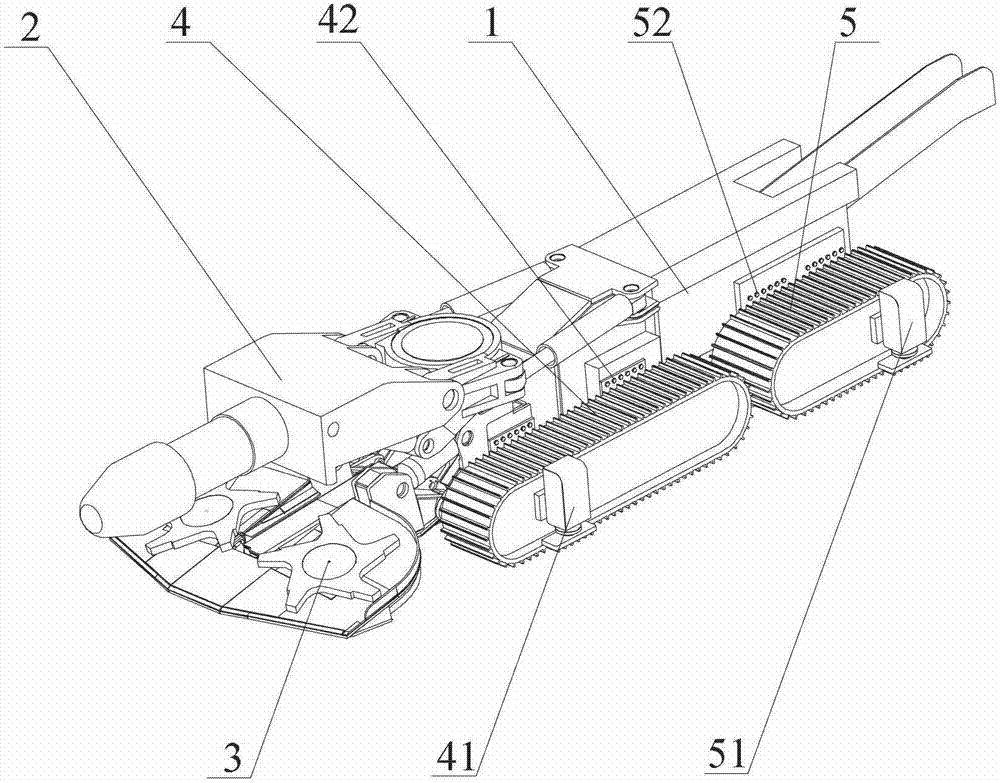

[0051] The dislocation arrangement structure in the second embodiment is, as Figure 8 As shown, the second group of crawler traveling mechanisms is arranged at a position close to the inner side of the roadheader body relative to the first group of crawler traveling mechanisms. The second set of tracked running gear spacing is even smaller.

Embodiment 3

[0052] In the third embodiment, the dislocation arrangement structure is, such as Figure 9 As shown, the second group of crawler running mechanisms is arranged at a position away from the inner side of the roadheader body relative to the first group of crawler running mechanisms. The second set of crawlers is spaced a little wider.

[0053] Multiple sets of crawler traveling mechanisms are arranged in dislocation to meet the working requirements of the roadheader under different working conditions. Make the roadheader more adaptable.

[0054] Further preferably, the first left crawler running mechanism 4 has the same width as the second left crawler running mechanism 5; the first right crawler running mechanism 6 has the same width as the second right crawler running mechanism 7 (not shown in the figure) out); to make the roadheader more practical for its different working environments.

[0055] As another option, the first left crawler running mechanism 4 is different in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com