A construction method for the lining structure of large-span and large-volume concrete tunnel with circular openings

A technology of mass concrete and construction method, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of reduced section stiffness, reduced shear performance, and impact on structural safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

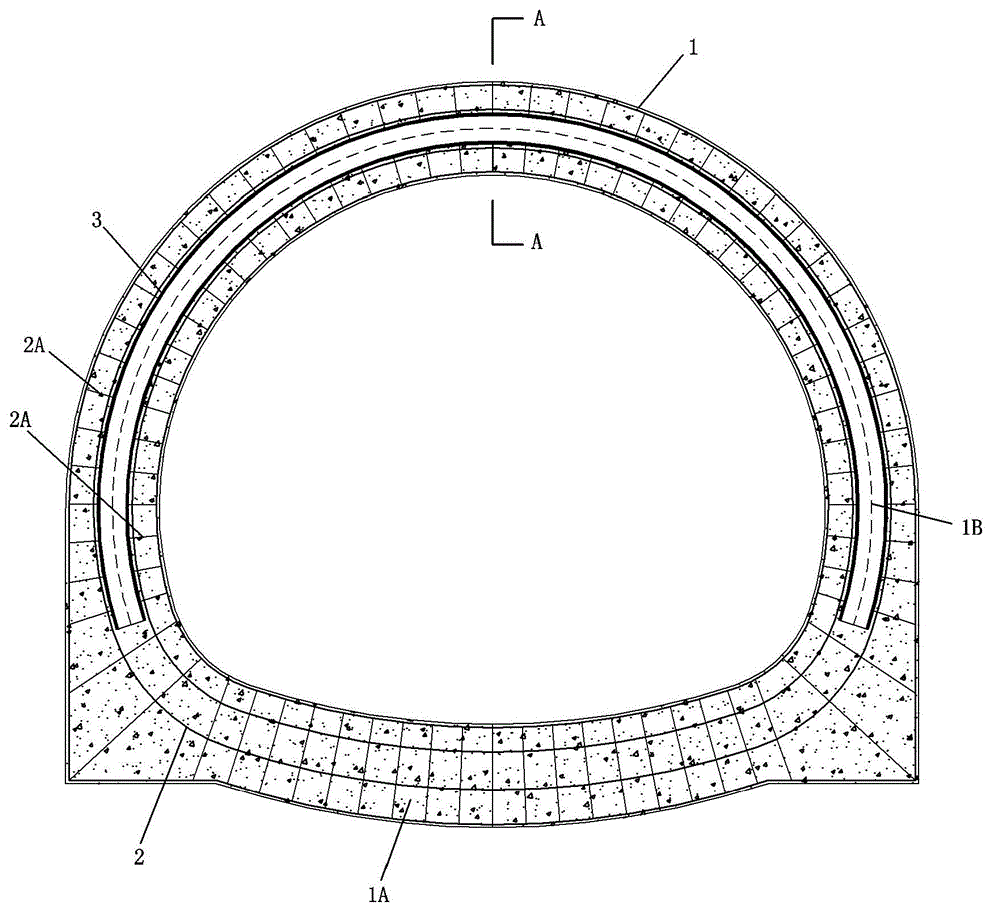

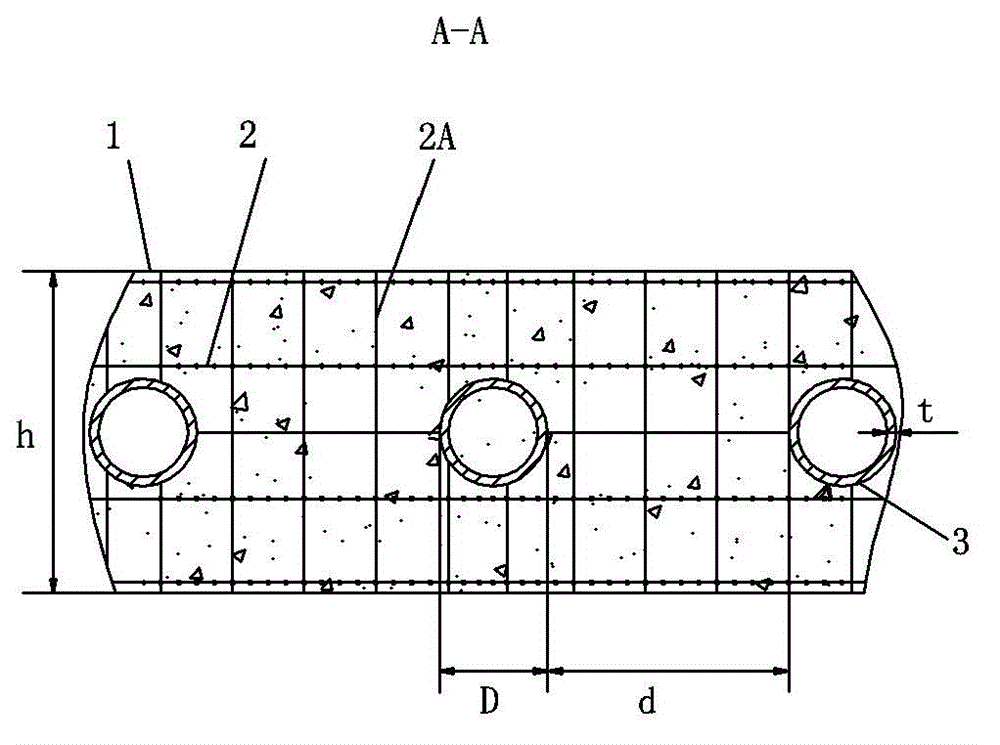

[0022] figure 1 , figure 2 It is shown that a specific embodiment of the present invention is: a method for constructing a large-span mass-volume concrete tunnel lining structure with circular openings, which is as follows:

[0023] a. Set up the formwork at the construction site of the lining 1 and bind the lining reinforcement 2;

[0024] b. Weld the arc-shaped steel pipe 3 on the erecting bar 2A in the lining steel bar 2, and the central axis of the arc-shaped steel pipe 3 coincides with the circumferential axis 1B of the lining 1 above the inverted arch 1A, and the arc-shaped steel pipe 3 along the tunnel Longitudinal equidistant distribution;

[0025] c. Pouring concrete.

[0026] The diameter D of the arc-shaped steel pipe 3 used in this example is 1 / 10 to 1 / 2 of the lining thickness h, the wall thickness t of the arc-shaped steel pipe 3 is 10-30 mm, and the longitudinal distance d between adjacent arc-shaped steel pipes 3 is arc-shaped 2 to 3 times the diameter D o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com