Pressure sensor debugging system and debugging method thereof

A pressure sensor and debugging system technology, which is applied to the measurement of fluid pressure, calibration/testing of force/torque/power measuring instruments, instruments, etc., can solve the problems of complex debugging process, long time-consuming sensor debugging, low efficiency, etc., to achieve The effect of a wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

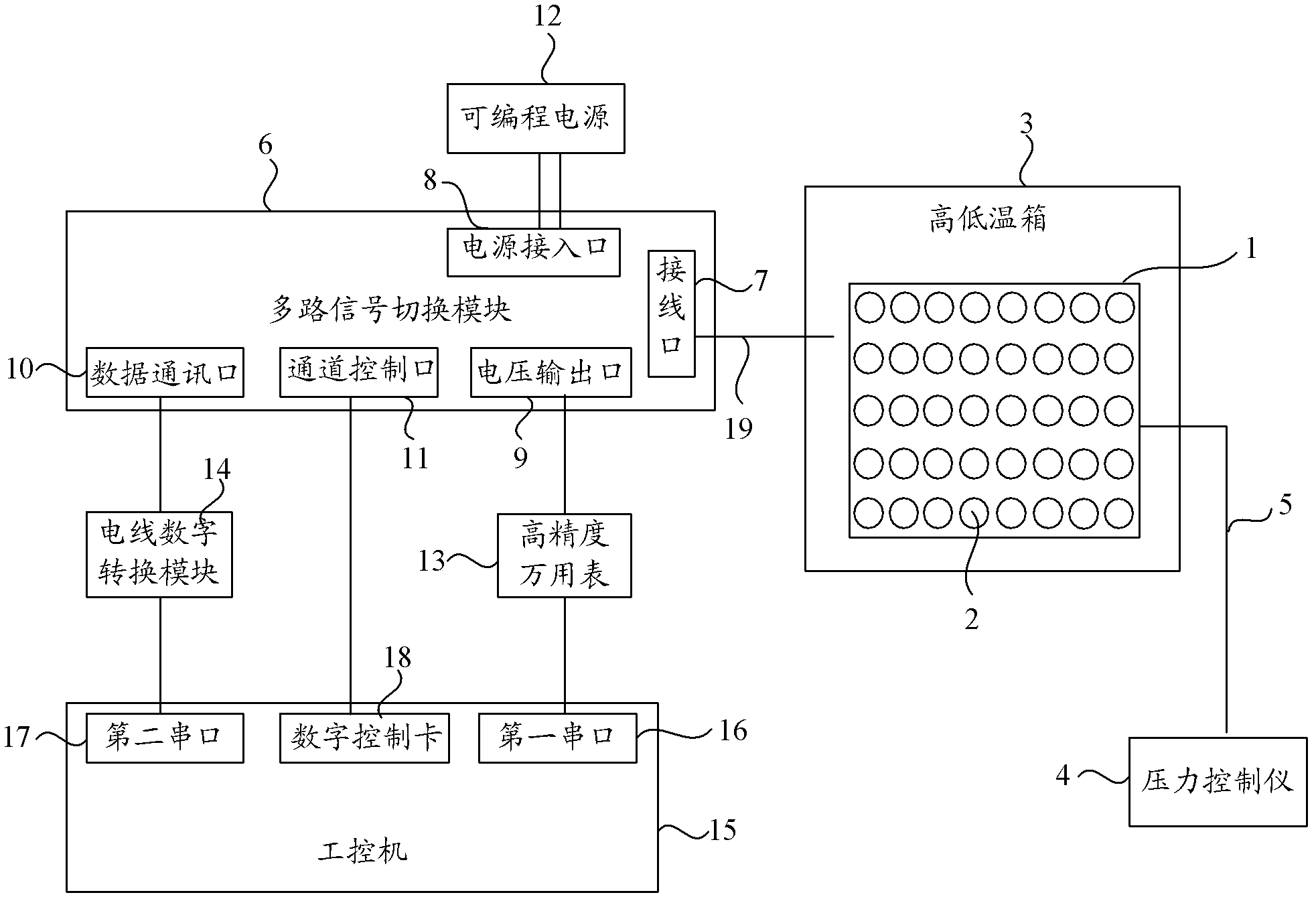

[0023] The pressure sensor debugging system and its debugging method proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that the drawings are all in a very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

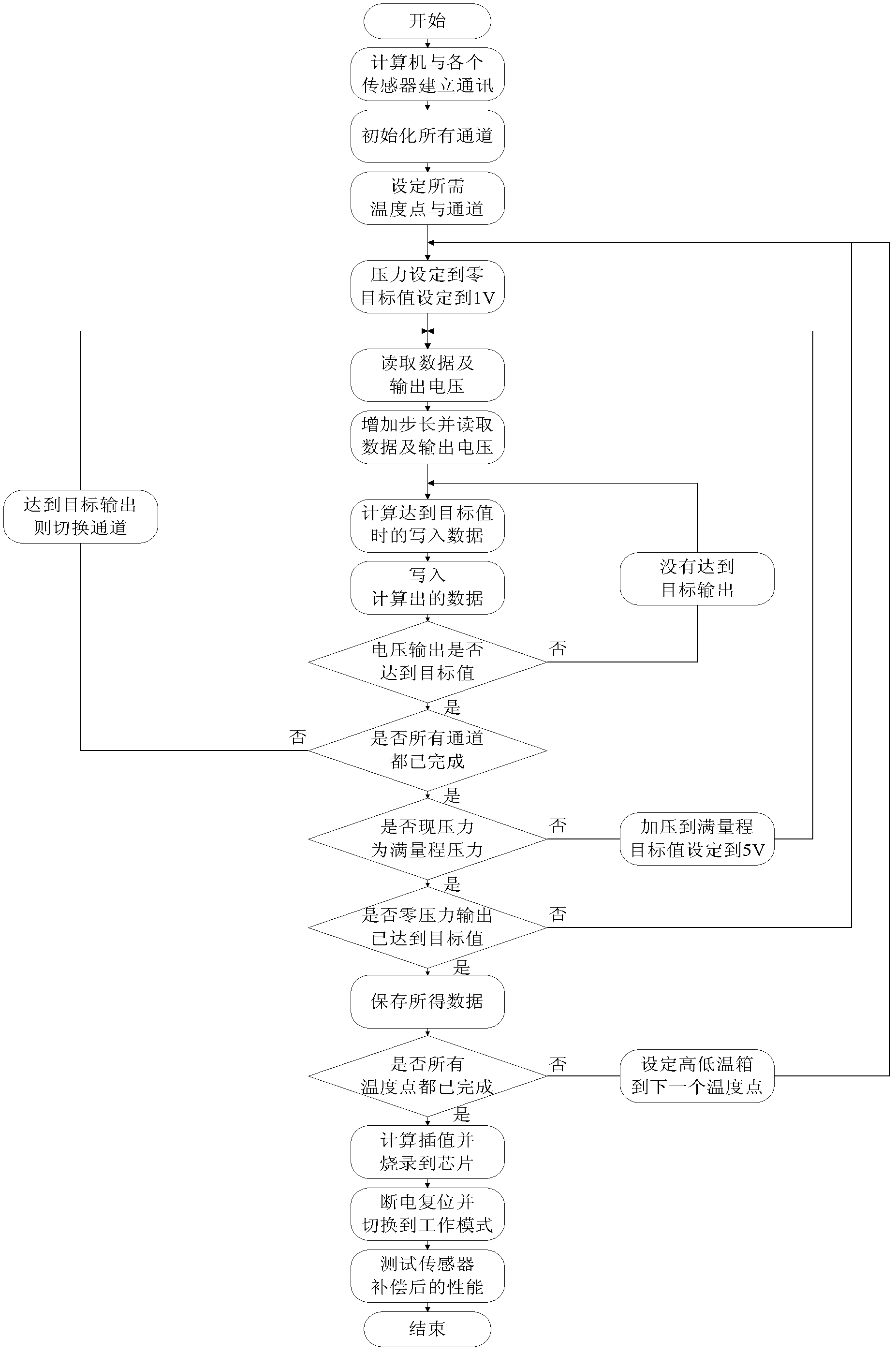

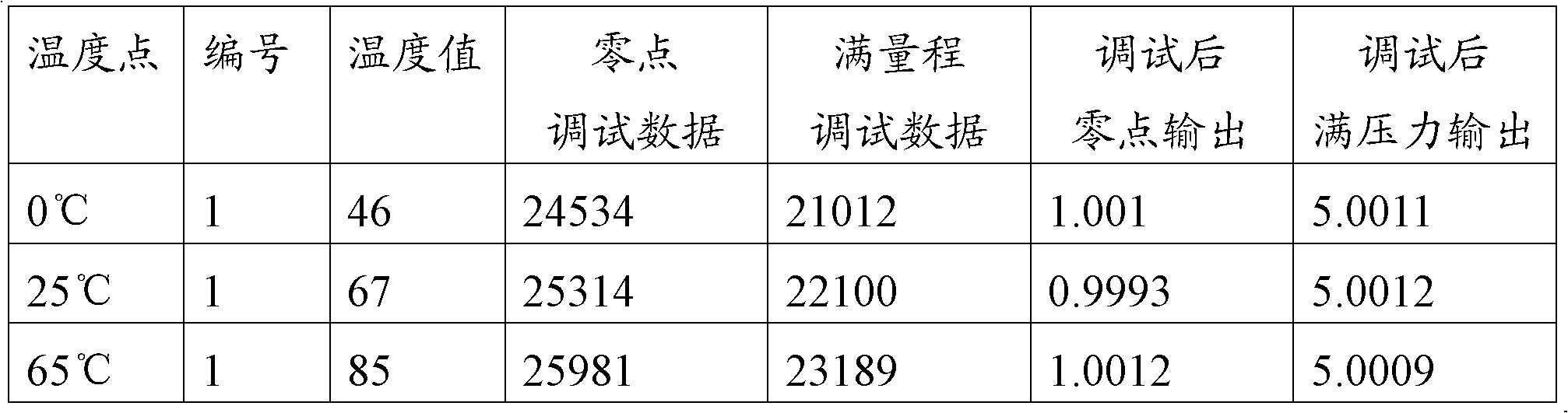

[0024] The core idea of the present invention is to provide a pressure sensor debugging system and its debugging method. The pressure sensor debugging system provides the required reference pressure for all the pressure sensors placed in the multi-channel sensor test pressure seat through the pressure controller, Set the ambient temperature required for debugging through the high and low temperature box, and then select one of the channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com