Sampling method of solution method for asphalt component separation

A solution method sampling and asphalt technology, applied in the direction of sampling devices, etc., can solve the problems of inaccurate experimental data, short softening time, easy aging of asphalt, etc., and achieve the effects of improving experimental efficiency, simple operation, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

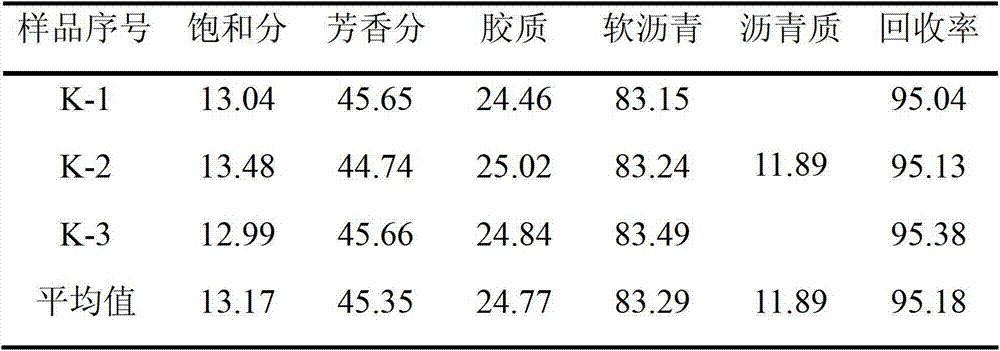

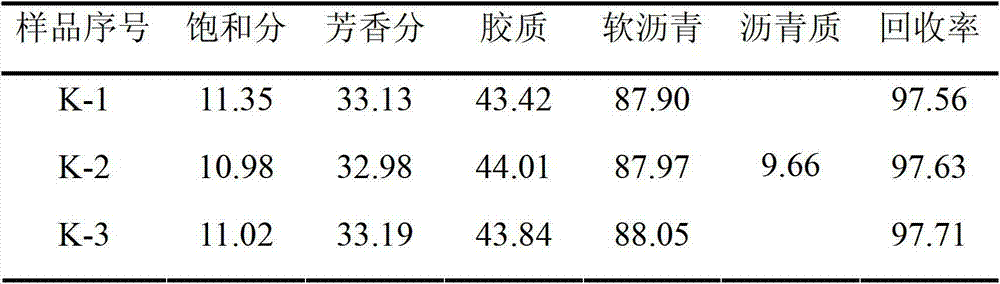

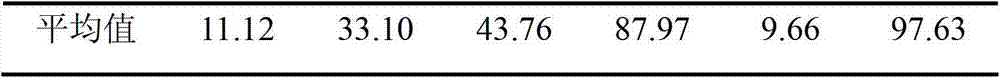

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with embodiment.

[0014] A solution-based sampling method for the separation of asphalt components, involving instruments including a 500mL round-bottom flask, a 500mL volumetric flask, a 150mL Erlenmeyer flask, a 50mL pot-bellied pipette, an ear wash ball, etc., specifically comprising the following steps:

[0015] Step 1: Set the volume of soft asphalt to a 500mL volumetric flask

[0016] 1) Measure the mass of the cleaned 500mL round bottom flask with a balance, accurate to 0.1mg;

[0017] 2) After step 1), weigh out 10g±1g of base asphalt in a round bottom flask;

[0018] 3) Add 300mL of activated n-heptane (refer to JTG E20-2011) into the 500mL round bottom flask, heat and boil for 1 hour to fully dissolve the soft asphalt in the base asphalt in the activated n-heptane, and then move it to a dark place to stand After standing for 2h, filter the solution in the round bottom flask with filter pap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com