Method for measuring electrode current through electrode current measuring device for low voltage compensation of submerged arc furnace

A technology of electrode current and measuring devices, which is applied in the direction of measuring devices, measuring current/voltage, and measuring electrical variables, etc. It can solve the problems that the electrode current cannot truthfully reflect the state of the electrode current, affect the rationality of electrode operation, and cannot obtain the electrode current correctly. , to achieve the effect of simple and convenient installation, small installation space and wide measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable the examiner to further understand the structure, features and other purposes of the present invention, the attached preferred embodiments are now attached in detail as follows with accompanying drawings, and the illustrated embodiments using the drawings are only used to illustrate the technology of the present invention scheme, not to limit the present invention.

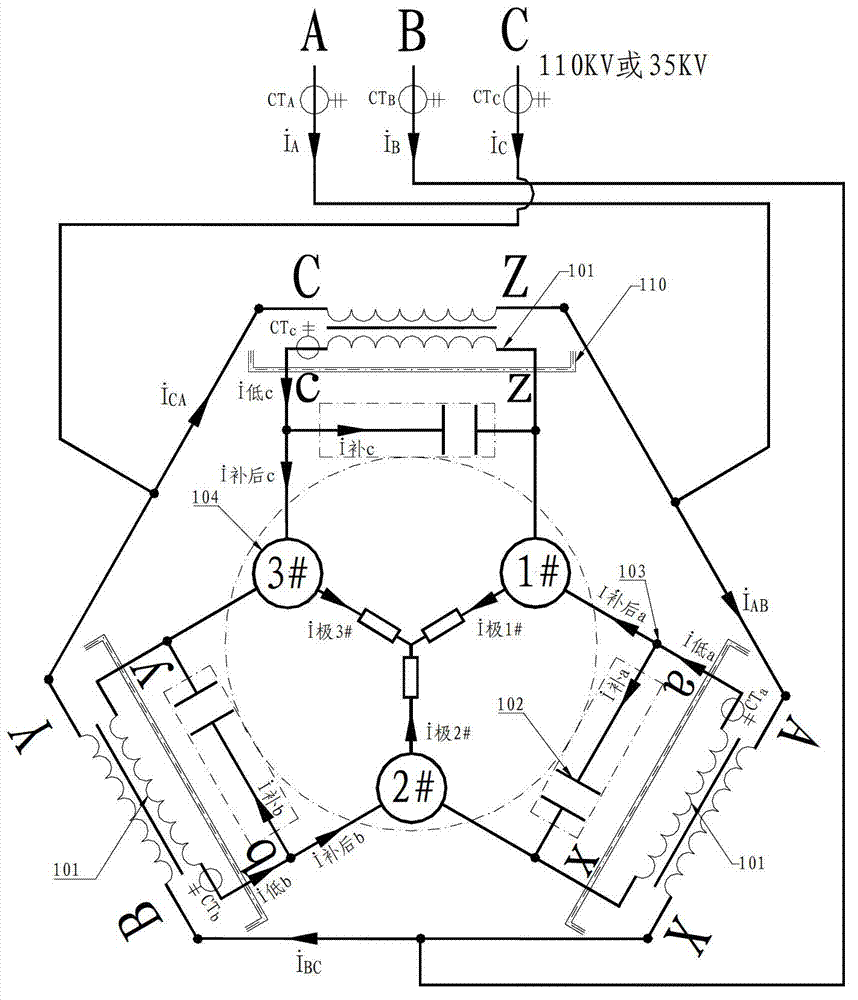

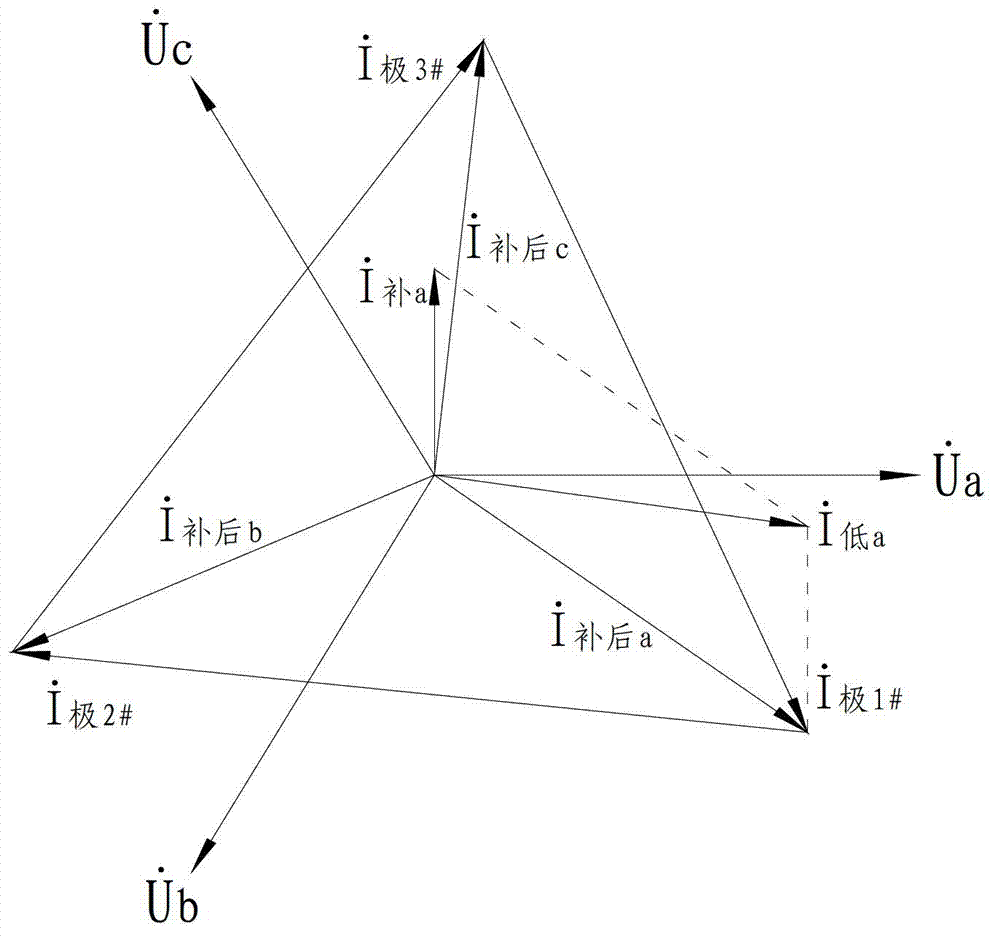

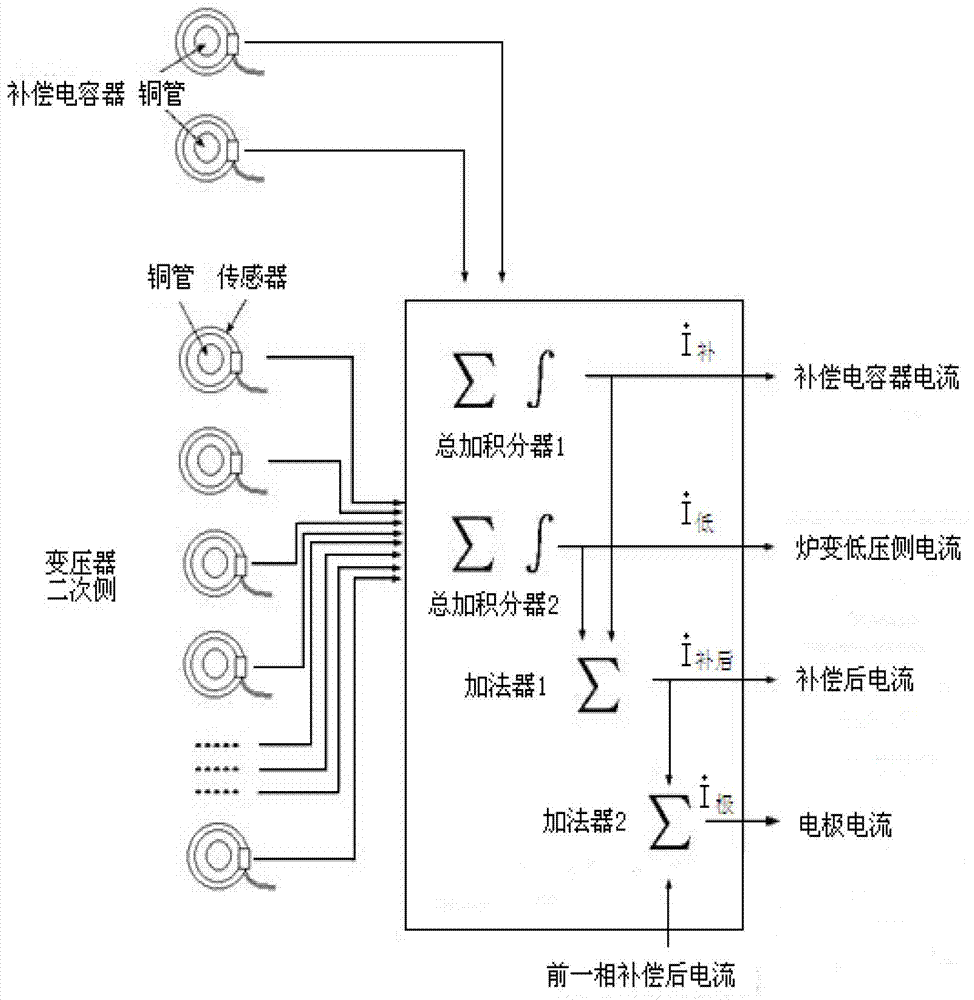

[0027] Such as figure 1 as shown, figure 1 It is a schematic diagram of the current transmission system of the submerged arc furnace. in, figure 1 The inside of the dotted line circle is the internal system of the furnace body, the dotted line box is the reactive power compensation system, and the rest are transformers and short network systems. Depend on figure 2 The vector synthesis method applied to the electrode current measuring device can be obtained from the current reference direction shown in .

[0028] Such as figure 1 As shown, in the low-voltage reactive power compensat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com