Passive multidomain VA (vertical alignment) type liquid crystal display and manufacturing process thereof

A liquid crystal display, passive technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of dispersion of display effect and unsatisfactory effect, and achieve the effect of increasing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

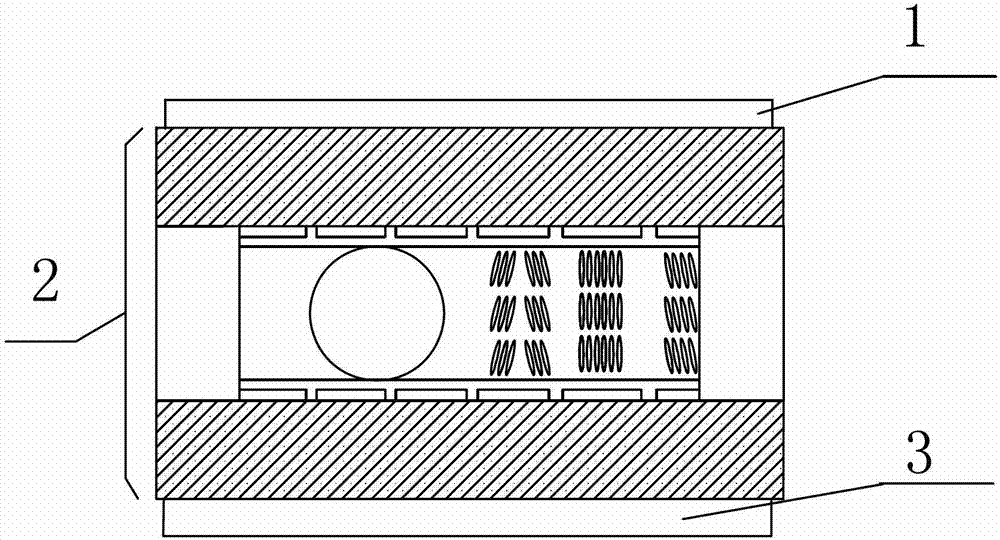

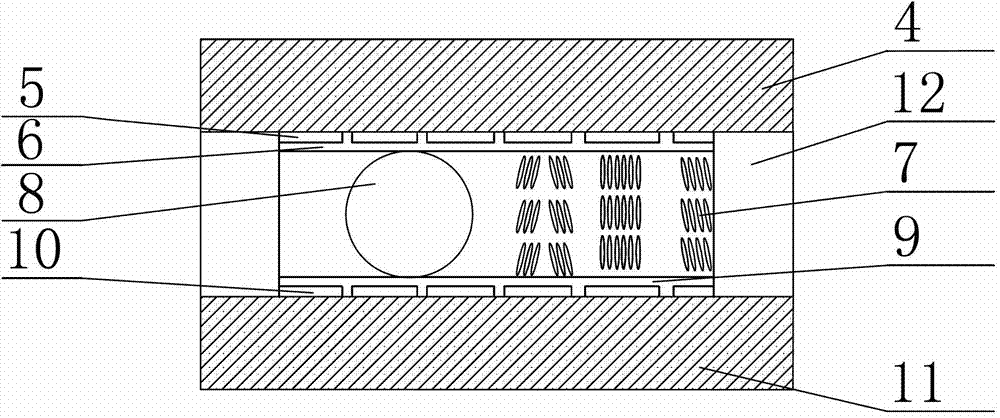

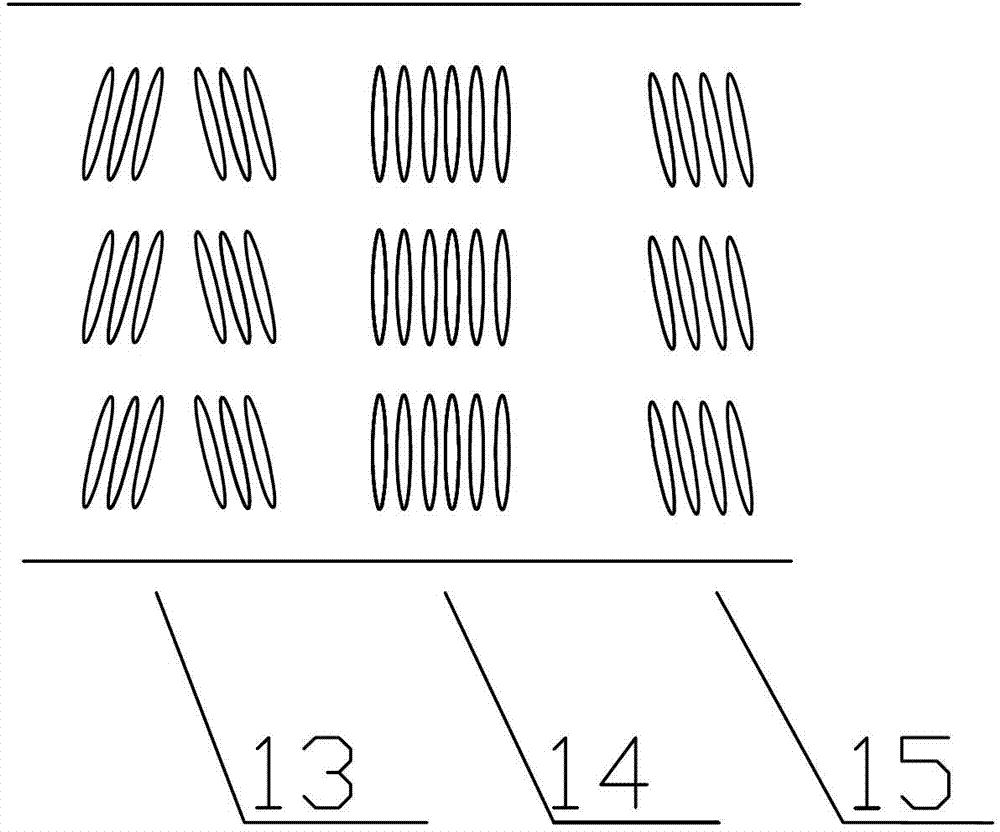

[0026] A passive multi-domain VA liquid crystal display, see figure 1 , including a (composite film) polarizer 1, a liquid crystal cell 2, and a (composite film) polarizer 3 arranged from top to bottom. See figure 2 The liquid crystal cell includes an upper glass substrate 4, an upper ITO layer 5, an upper PI alignment layer 6, a liquid crystal layer 7, a spacer 8, a lower PI alignment layer 9, a lower ITO layer 10, and a lower glass substrate 11 arranged from top to bottom. , also includes frame glue 12 for closing the frame. In the liquid crystal layer 7, spacers 8 are evenly distributed with a density range of 60-180 per square millimeter, and the surroundings are filled with liquid crystals 7; the liquid crystal layer 7 is vertically aligned nematic, with a thickness ranging from 3.0 μm to 6.0 μm; the upper glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com