Electric automobile dynamic equalizing charge method

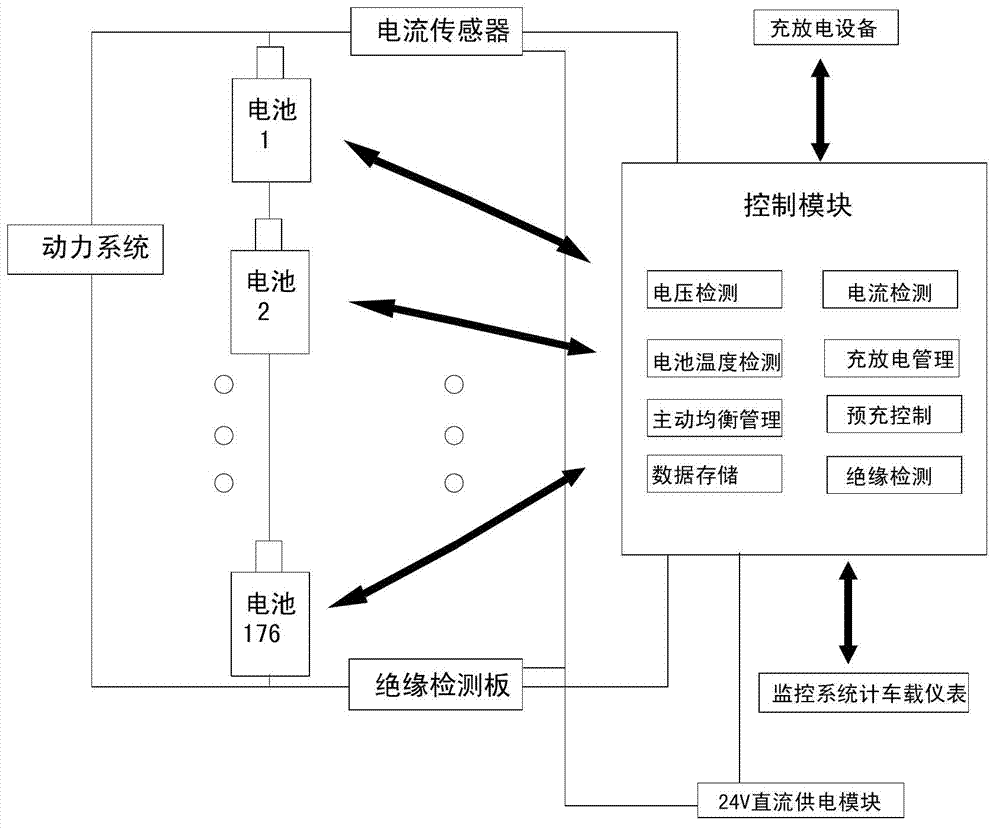

An electric vehicle and dynamic equalization technology, which is applied in electric vehicles, battery circuit devices, current collectors, etc., can solve the problems of small discharge current, inconsistent performance of single batteries, and can not really eliminate the inconsistency of battery packs, etc., to achieve the elimination of inconsistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

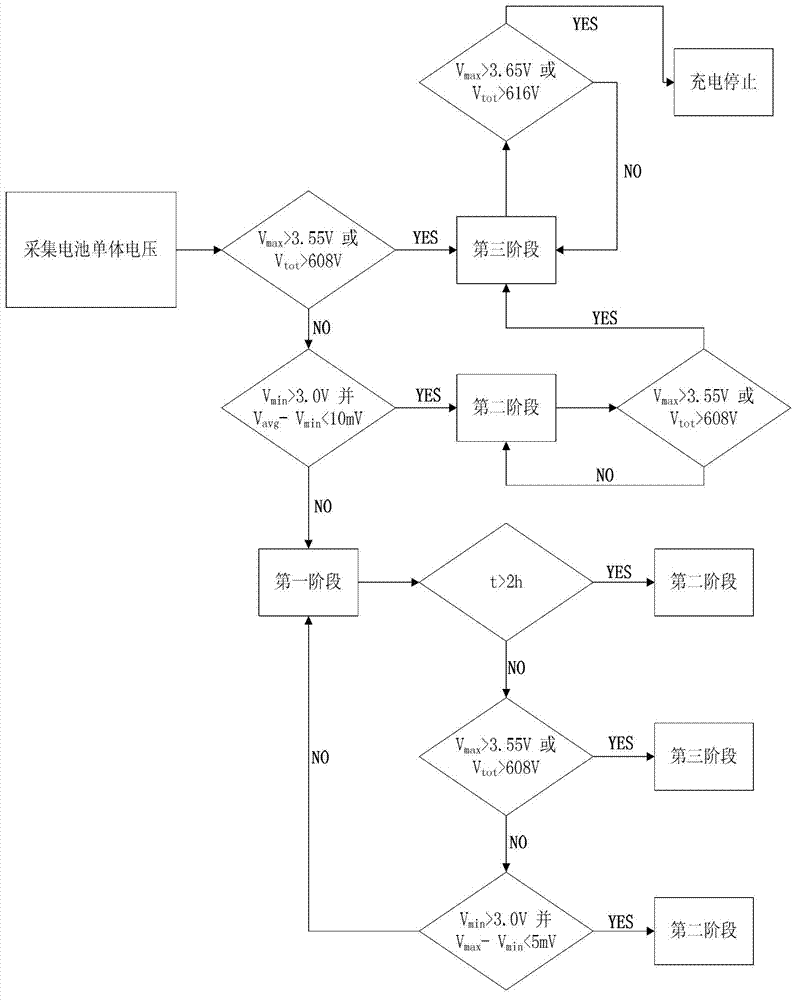

[0023] When charging the battery of an electric vehicle, when the voltage of any battery cell in the battery pack is greater than 3.55V or the overall voltage is greater than 608V, the voltage reduction charging process (third stage) is performed, and the charging current is reduced to 50A; When the voltage of a single battery is greater than 3.575V or the overall voltage is greater than 610V, the charging current is reduced to 612V, and the charging current is reduced to 20A; when the voltage of any single battery in the battery pack is greater than 3.625V or the overall voltage is greater than 614V, the charging current is reduced to 10A; When the voltage of any battery cell in the battery pack is greater than 3.65V or the overall voltage is greater than 616V, stop charging the battery pack.

Embodiment 2

[0025] When charging the battery pack of an electric vehicle, when it is detected that the voltage of all battery cells in the battery pack is greater than 3V and not more than 3.55V, and the minimum battery cell voltage is lower than the average value and less than 10mv, and the overall battery voltage is not more than 608V , directly carry out the 100A current constant current charging process (the second stage); when the voltage of any one battery cell is greater than 3.55V or the overall battery voltage is greater than 608V, the current constant current charging process is ended, and the step-down charging process described in Example 1 is entered (third stage) until the end of charging.

Embodiment 3

[0027] When charging the battery of an electric vehicle, if the following two conditions are met at the same time, it will enter the 40A current constant current pre-charging process (first stage). Condition (1): When it is detected that the voltage of all battery cells in the battery pack is not Greater than 3.55V and the overall battery voltage is not greater than 608V; Condition (2): The voltage of any single battery is not greater than 3V or the lowest battery voltage in the battery pack is lower than the average value and not less than 10mv.

[0028] If the 40A current constant current precharging process exceeds 2 hours and the following two conditions are met at the same time, the 40A constant current precharging process ends and the 100A current constant current charging process (second stage) is entered. Condition (1): All cells When the battery voltage is still not greater than 3.55V, and the overall battery voltage is still not greater than 608V; condition (2) the vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com