Motor stator and manufacturing method thereof

A motor stator and manufacturing method technology, applied in the field of motor stator and its manufacturing, can solve problems such as large no-load stray loss, increased slot leakage reactance, and increased difficulty of embedding wires, so as to improve motor performance and wire embedding speed , The effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

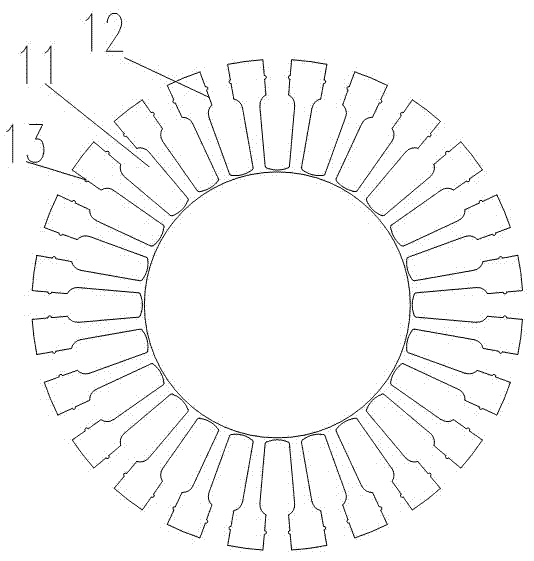

[0021] Example 1, such as figure 1 As shown in the iron core body 1 , the iron core body is provided with a strip-shaped groove 11 from the center to the circumferential direction, and the width of the strip-shaped groove is reduced near the circumference 12 and a protrusion 13 is provided.

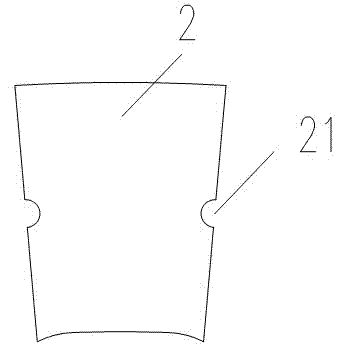

[0022] Such as figure 2 As shown, the core sealing piece 2 is provided with a groove 21 corresponding to the protrusion 13 .

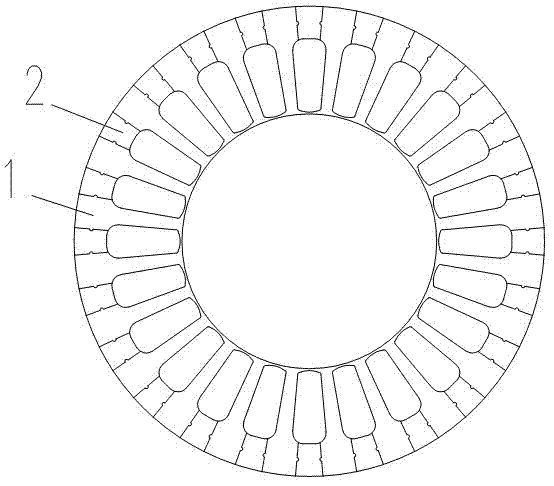

[0023] Such as image 3 As shown, the iron core main body 1 is combined with the iron core sealing piece 2 to form an iron core, and the iron core sealing piece 2 is inserted into the vicinity of the circumference 12 of the strip groove 11 of the iron core main body 1, so that the groove 21 cooperates with the protrusion 13 and the The iron core closing piece 2 is limited on the iron core main body 1 .

[0024] The above-mentioned multi-piece iron core main body 1 and the iron core sealing piece 2 are superimposed to form the motor stator.

Embodiment 2

[0025] Embodiment 2, similar to Embodiment 1, the main difference is that the buckle between the iron core body and the iron core sealing piece changes, and the protrusion on the iron core body becomes a groove, and the corresponding iron core seals The grooves of the sheet are changed to protrusions, but are not shown in the figure because they are easy to understand.

[0026] The above motor stator can be prepared according to the following method: 1) Select a square iron sheet 3, punch out the iron core main body 1 and the iron core sealing sheet 2 on the iron sheet 3 according to the shape of the iron core main body 1 and the iron core sealing sheet 2, Figure 4 According to the layout diagram of the shape of the iron core main body 1 and the iron core sealing piece 2 before punching, Figure 5 In order to punch out the iron core main body 1 and the remaining iron sheet of the iron core sealing piece 2; 2) Insert the iron core sealing piece 2 into the bar-shaped groove of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com