Air distribution system of filter

A filter and gas distribution technology, applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the problems of high installation cost, high pipeline cost, low gas distribution performance, etc., and achieve low maintenance cost , Reduce pipeline cost and installation cost, simple construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

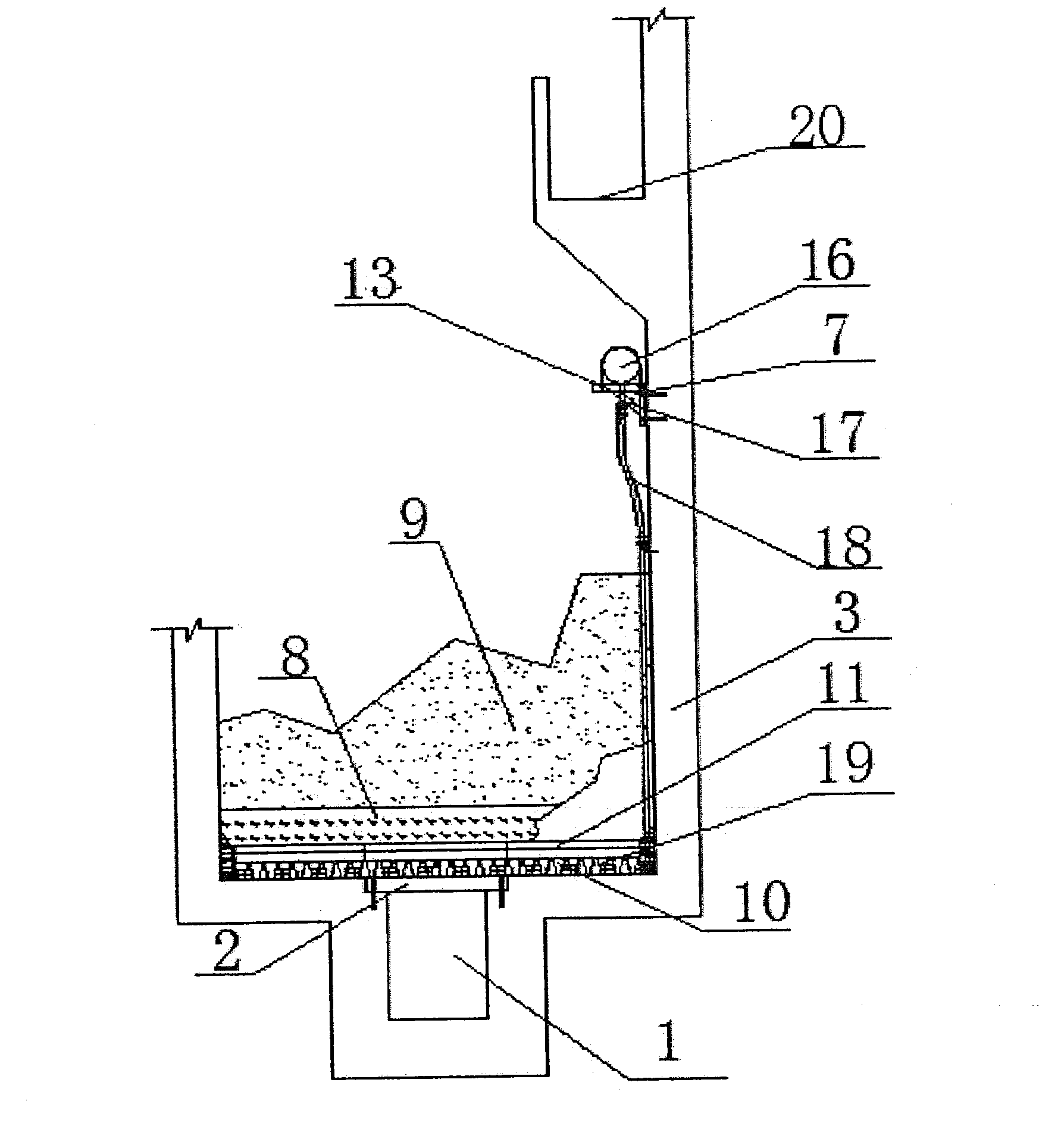

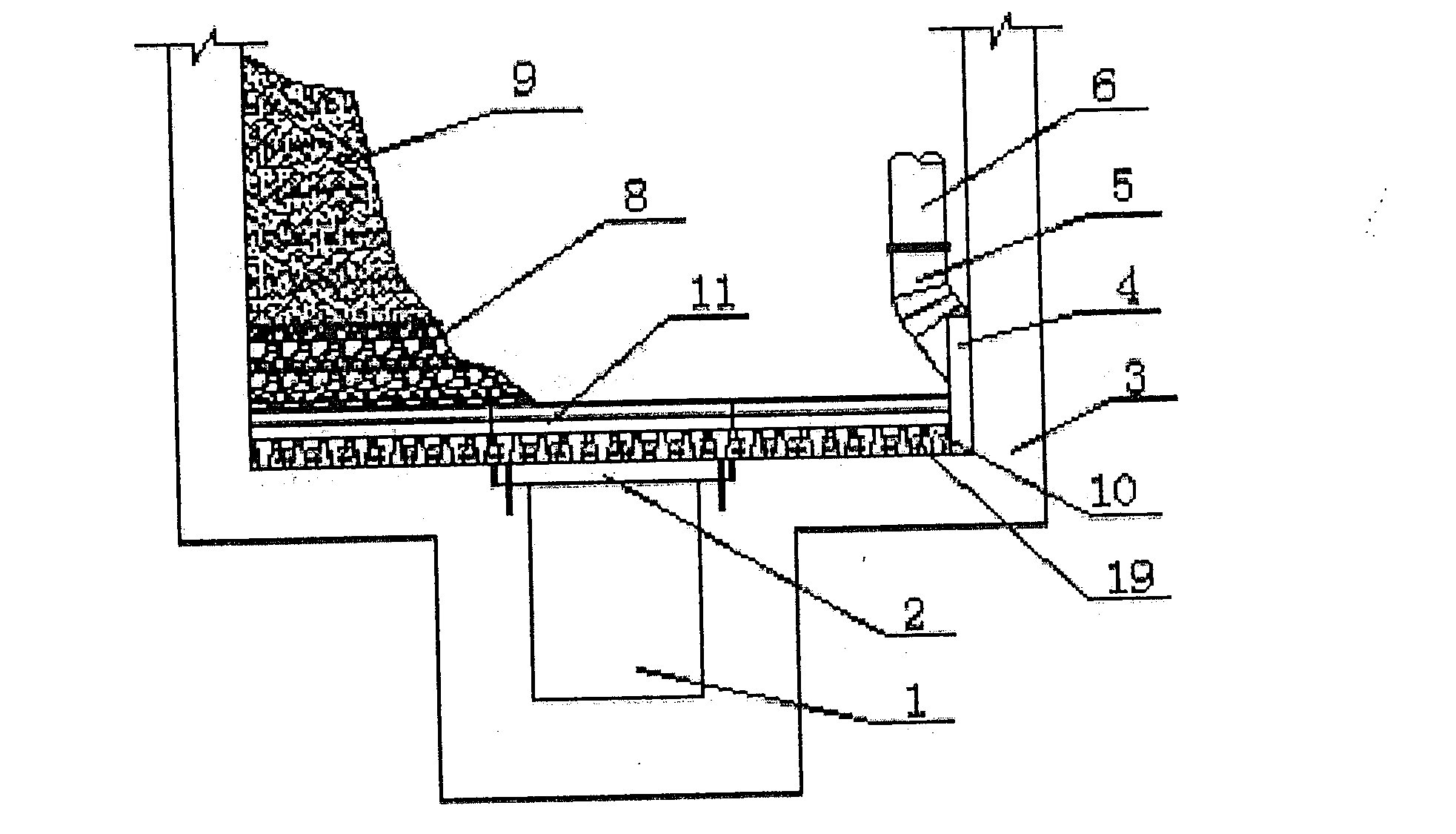

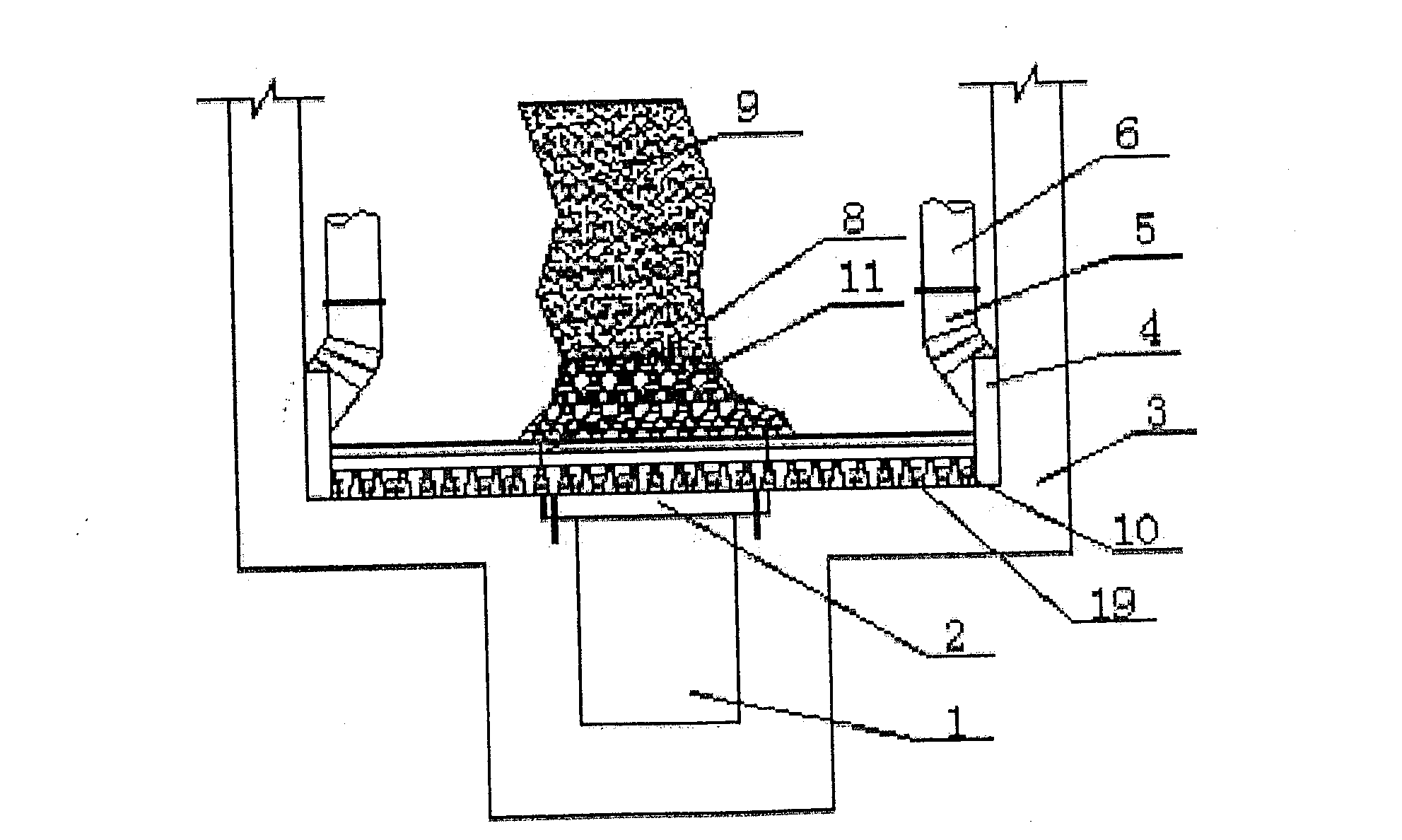

[0012] Such as figure 1 , Figure 4 and Figure 5 As shown, a filter gas distribution system includes a recoil channel 1, a filter 3 and an air distribution pipe group 7, the filter 3 is arranged on the recoil channel 1, and a recoil channel is provided at the upper end of the recoil channel 1 The upper cover plate 2 of the water channel, the bottom of the filter 3 is sequentially provided with a gas distribution branch pipe layer 10 and a filter brick group 11, and the filter brick group 11 is laid on the gas distribution branch pipe layer 10, and the gas distribution branch pipe layer 10 It is composed of several L-shaped perforated gas distribution branch pipes 19. The filter brick group 11 is composed of several filter bricks 12 evenly laid. Each filter brick 12 is equipped with a plug 14 at both ends, and the plug 14 is connected with the filter tank wall. The spaces are filled with concrete 15; the gravel support layer 8 and the filter material layer 9 are arranged seq...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap